Coating diaphragm with high flame retardance and lithium dendrite growth inhibition function and preparation method of coating diaphragm

A technology of lithium dendrites and high flame retardancy, which is applied in the field of coating separators with high flame retardancy and inhibition of lithium dendrite growth and its preparation, can solve problems such as thermal runaway, short-circuiting of lithium-ion batteries, and degradation of battery cycle performance. Achieve good high temperature resistance and thermal conductivity, improve the ability to resist open flames, and improve the effect of battery safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

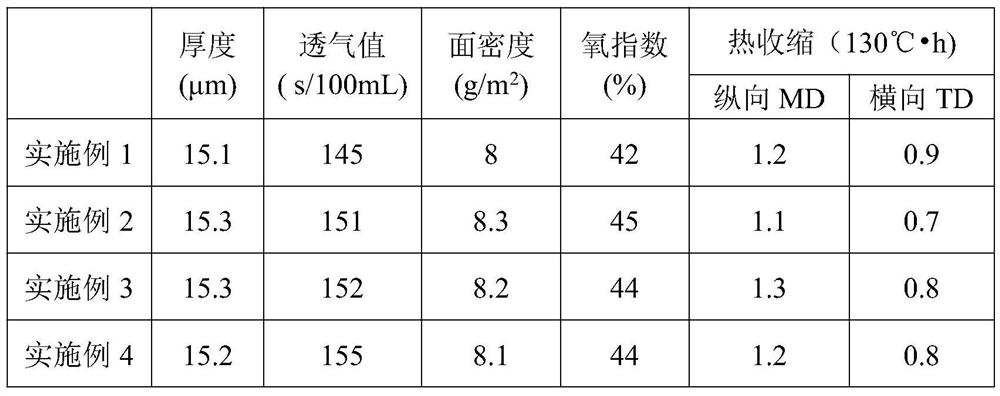

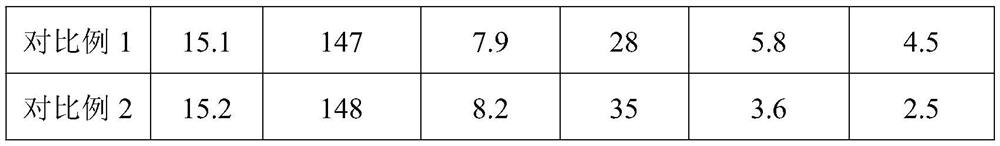

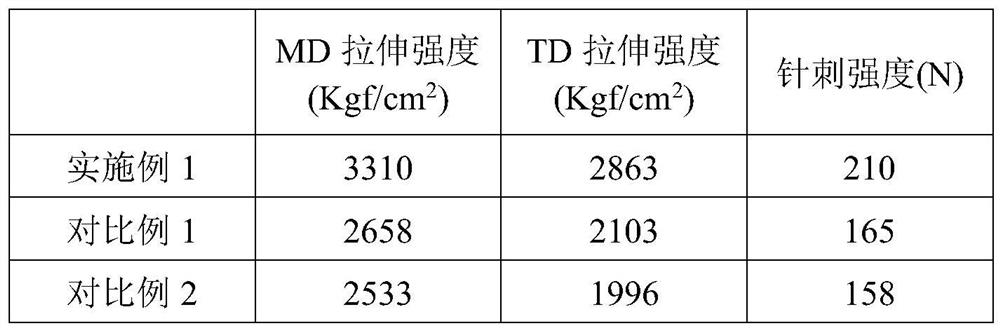

Examples

preparation example Construction

[0032] Fabrication of BNNS Nanosheets: Using Ultrasonic-Assisted Liquid-Phase Exfoliation.

[0033] (1) The hexagonal boron nitride powder of 1.5g is dispersed in the mixed solvent of 300mL isopropanol and ultrapure water (the volume ratio of isopropanol and ultrapure water is 1:1), in the process, the ultrasonic cleaning machine The power is 180W, and the ultrasonic stripping time is 12h; after stripping, the obtained dispersion is centrifuged at 2000rpm for 20min to remove the remaining unstripped hexagonal boron nitride, and finally the supernatant after centrifugation is vacuum filtered and stored at 100°C After drying for 10 h, BNNS nanosheets were obtained.

[0034](2) Preparation of functionalized BNNS nanosheets: using sol-gel method.

[0035] First, an appropriate amount of APTES (3% of the mass of BNNS) was added to 100 mL of absolute ethanol, and stirred at 60° C. for 30 min to fully hydrolyze APTES. Then 2g of BNNS was dispersed into the solution, stirred at 80°C...

Embodiment 1

[0037] Step 1: First, stir 26Kg of ultrapure water, 0.24Kg of dispersant and 8Kg of functionalized BNNS nanosheets to obtain a BNNS dispersion, and then add 16Kg of Mg(OH) 2 Stir the powder to mix the solution evenly, then add 3.2Kg of thickener and mix evenly; grind the obtained slurry to D90<2.0μm through a sand mill, and finally add 3.5Kg of binder, 0.2Kg of moistening The wet agent is stirred evenly to coat the slurry.

[0038] Step 2: Coating slurry on both sides of the base film: using the micro-gravure roll coating process, the prepared coating slurry is coated on both sides of the 9 μm polyethylene base film step by step through the coating machine, and the coating thickness is The thickness is 3 μm, and the separator A is obtained after being baked in an oven at 70°C.

[0039] Step 3: Using methanol and tris buffer solution with pH=8.5 as co-solvents (methanol:buffer solution=1:1), immerse the diaphragm A in 0.01mol polydopamine solution for surface modification. Af...

Embodiment 2

[0041] Step 1: First, stir 20Kg of ultrapure water, 0.15Kg of dispersant and 5Kg of functionalized BNNS nanosheets to obtain a BNNS dispersion, and then add 10Kg of Mg(OH) 2 Stir the powder to mix the solution evenly, then add 1Kg of thickener and mix evenly; grind the obtained slurry to D90<2.0μm through a sand mill, and finally add 1Kg of binder and 0.15Kg of wetting agent and mix evenly Slurry must be applied.

[0042] Step 2: Immerse the base film in an aqueous solution of 1.8 mg / L tannic acid for 10 minutes, then transfer to an aqueous solution of 0.1 mmol / L sodium periodate and immerse for 5 minutes; cycle 2 times; coat on both sides Slurry: Using the micro-gravure roller coating process, the prepared coating slurry is coated on both sides of a 9 μm polyethylene-based film step by step through a coating machine, with a coating thickness of 3 μm, and baked in a 70°C oven Then wind up the separator A.

[0043] Step 3: Using methanol and tris buffer solution with pH=8.5 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com