Self-tackifying diverting acid liquor thickening agent as well as preparation method and application thereof

A technology of turning to acid and thickener, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve problems such as temperature lower than 120 ℃, limited acid liquid injection and displacement, and temperature resistance defects, etc., to achieve reduction Ground pump pressure, increase the action distance, and improve the effect of acidification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

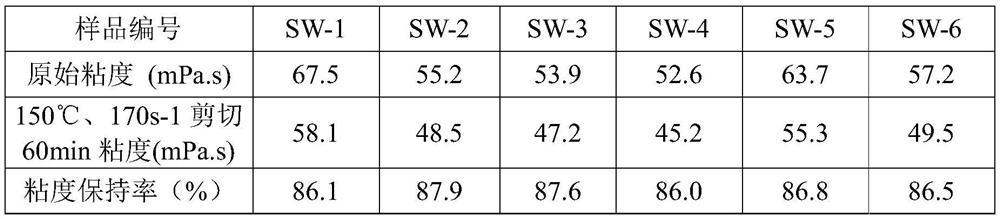

Examples

Embodiment 1

[0043] The present embodiment provides a kind of preparation method of self-viscosification diverting acid liquid thickener, specifically comprises the following steps:

[0044] 1. Fully mix dimethyldiallylammonium chloride, octadecyldimethylallyl ammonium chloride, acrylamide, and acryloylmorpholine in distilled water at a mass ratio of 7:0.2:2:0.8 , prepared as an intermediate solution with a mass concentration of 30%, adding glacial acetic acid and sodium carbonate as pH regulators until the pH of the intermediate solution reaches 6.3, and placing the intermediate solution in an oil bath for temperature control.

[0045] 2. Adjust the temperature of the oil bath to -3°C, and continuously feed 99.999% high-purity nitrogen into the intermediate solution. After 30 minutes, add ethylenediamine, ammonium persulfate, and hydrogen sulfite with a mass ratio of 5.5:3:1.5 A low-temperature initiation system formed by potassium, then adding potassium formate as a molecular weight regu...

Embodiment 2

[0049] This embodiment provides a kind of preparation method of self-viscosifying and diverting acid liquid thickener, and its difference with embodiment 1 is that the mass concentration of intermediate solution is different, specifically comprises the following steps:

[0050] 1. Fully mix dimethyldiallylammonium chloride, octadecyldimethylallyl ammonium chloride, acrylamide, and acryloylmorpholine in distilled water at a mass ratio of 7:0.2:1.8:1 , prepared as an intermediate solution with a mass concentration of 40%, adding glacial acetic acid and sodium carbonate as a pH regulator until the pH of the intermediate solution reaches 6.3, and placing the intermediate solution in an oil bath for temperature control.

[0051] 2. Adjust the temperature of the oil bath to -3°C, and continuously feed 99.999% high-purity nitrogen into the intermediate solution. After 30 minutes, add ethylenediamine, ammonium persulfate, and hydrogen sulfite with a mass ratio of 5.5:3:1.5 A low-tempe...

Embodiment 3

[0055] The present embodiment provides a kind of preparation method of turning to acid thickener from thickening, and its difference with embodiment 1 is that the mass ratio between the solute of intermediate solution and the mass concentration of intermediate solution are different, specifically comprises the following steps:

[0056] 1. Fully mix dimethyldiallylammonium chloride, octadecyldimethylallyl ammonium chloride, acrylamide, and acryloylmorpholine in distilled water at a mass ratio of 8:0.2:0.8:1 , prepared as an intermediate solution with a mass concentration of 40%, adding glacial acetic acid and sodium carbonate as a pH regulator until the pH of the intermediate solution reaches 6.3, and placing the intermediate solution in an oil bath for temperature control.

[0057] 2. Adjust the temperature of the oil bath to -3°C, and continuously feed 99.999% high-purity nitrogen into the intermediate solution. After 30 minutes, add ethylenediamine, ammonium persulfate, and h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com