Temperature-resistant and salt-resistant polymer containing cyclic structure as well as preparation method and application of temperature-resistant and salt-resistant polymer

A ring-shaped, temperature-resistant and salt-resistant technology, applied in the fields of oil exploration and tertiary oil recovery polymer flooding, can solve the problems of precipitation, reduction of oil-water mobility ratio, loss of oil displacement capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

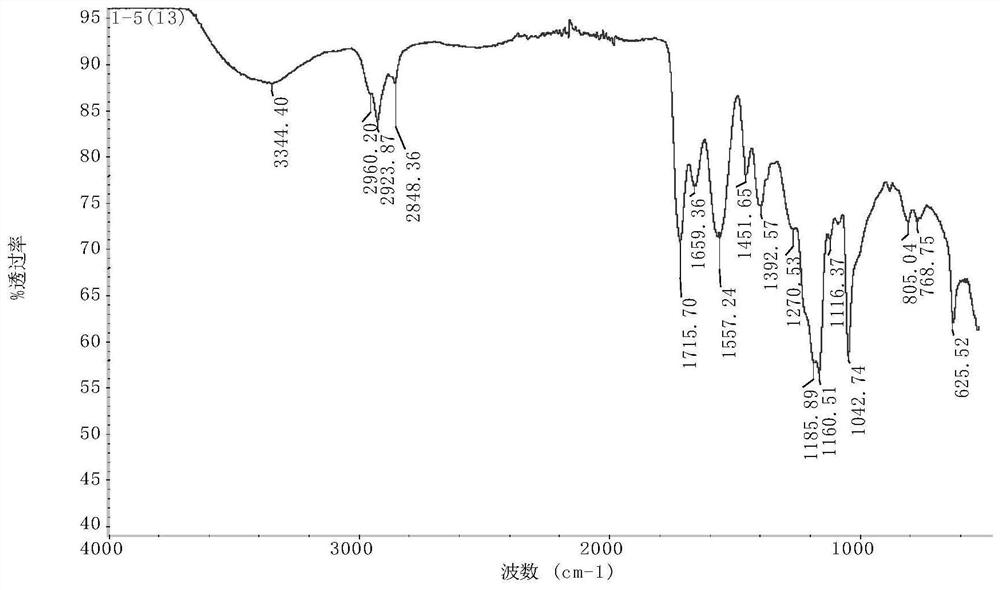

[0062] This embodiment provides a temperature-resistant and salt-resistant polymer containing a ring structure, which is prepared by the following steps:

[0063] First add 725g of distilled water to a 1L jar, add 200g of acrylamide monomer AM, then add 50g of acrylic acid monomer AA, mix well, turn the stirring speed to 1000 rpm, mix well, dissolve completely, and then oxidize with hydrogen Adjust the pH of the aqueous solution to 7.0±0.5 with sodium, then add 8g of sodium p-styrenesulfonate under stirring conditions, then add 6g of acryloylmorpholine, and then cool down to 15°C; Deoxygenation with high-purity nitrogen above % for 10 minutes, adding 1.5 g of polymerization catalyst 3-aminopropionitrile, continuing nitrogen deoxygenation for 20 minutes, adding 1.2 g of azobisisoheptanonitrile, and nitrogen deoxygenation for 20 minutes, then adding ammonium persulfate 0.008g, and then add 0.02g of sodium bisulfite after 2 minutes, then continue to pass nitrogen until the soluti...

Embodiment 2

[0066] This embodiment provides a temperature-resistant and salt-resistant polymer containing a ring structure, which is prepared by the following steps:

[0067] Add 722g of distilled water to a 1L jar, add 240g of acrylamide monomer AM, then add 50g of acrylic acid monomer AA, mix evenly, turn the stirring speed to 1000 rpm, mix evenly, dissolve completely, and then oxidize with hydrogen Adjust the pH of the aqueous solution to 7.0±0.5 with sodium, then add 10g of sodium p-styrenesulfonate under stirring conditions, then add 7g of acryloylmorpholine, and then cool down to 18°C; Deoxygenation with high-purity nitrogen above % for 10 minutes, adding 1.8 g of polymerization catalyst 3-aminopropionitrile, continuing nitrogen deoxygenation for 20 minutes, adding 2.4 g of azobisisoheptanonitrile, and nitrogen deoxygenation for 20 minutes, then adding ammonium persulfate 0.008g, and then add 0.02g of sodium bisulfite after 2 minutes, then continue to pass nitrogen until the solutio...

Embodiment 3

[0070] This embodiment provides a temperature-resistant and salt-resistant polymer containing a ring structure, which is prepared by the following steps:

[0071] First add 721g of distilled water to a 1L jar, add 220g of acrylamide monomer AM, then add 35g of acrylic acid monomer AA, mix well, turn the stirring speed to 1000 rpm, mix well, dissolve completely, and then use sodium hydroxide Adjust the pH of the aqueous solution to 7.0±0.5, then add 8g of sodium p-styrenesulfonate under stirring conditions, then add 6g of acryloylmorpholine, and then cool down to 20°C; The above high-purity nitrogen was deoxygenated for 10 minutes, and 3.6 g of the polymerization catalyst 3-aminopropionitrile was added, and 1.8 g of azobisisoheptanonitrile was added after continuing nitrogen deoxygenation for 20 minutes, and ammonium persulfate 0.010 was added after nitrogen deoxygenation for 20 minutes. g, 0.03 g of sodium bisulfite was added after 2 min, and then nitrogen gas was continued un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com