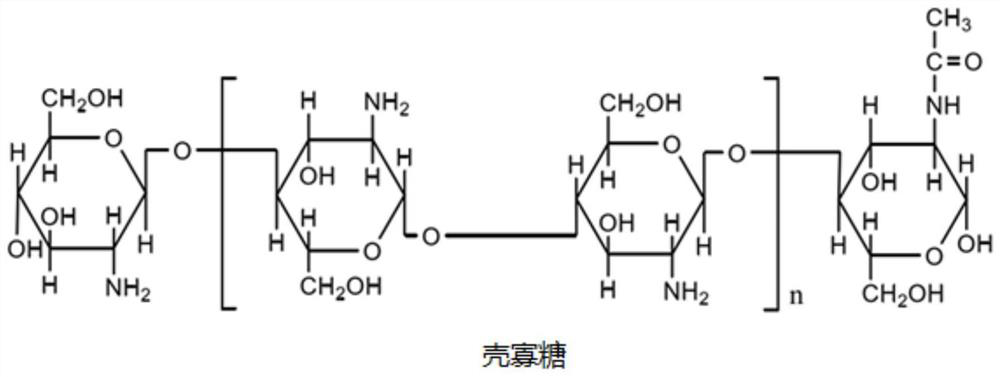

LIG material as well as preparation method and application thereof

A preparation process and precursor technology, which is applied in the field of LIG material preparation, can solve problems such as hindering large-scale production, environmental pollution, and difficulty in forming membranes, etc., to achieve industrial application, simple preparation process, and simple and easy process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

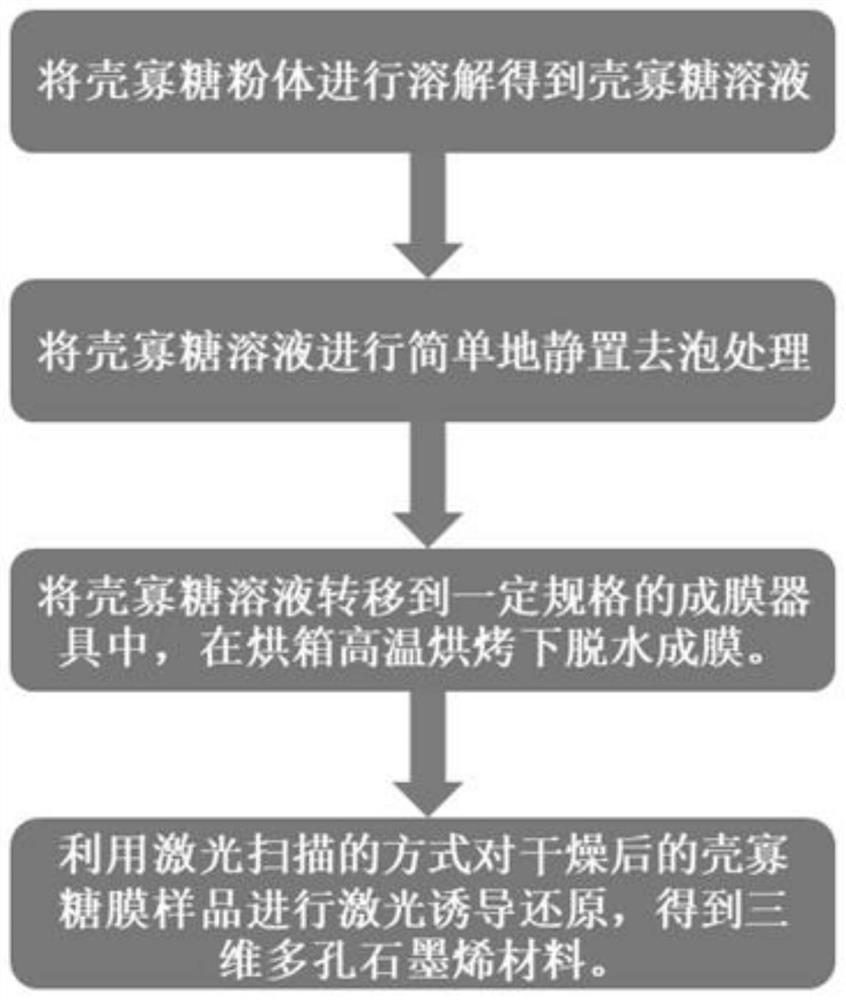

[0053] This embodiment provides a method for preparing a LIG material, comprising the following steps:

[0054] (1) Weigh 10 grams of chitosan oligosaccharide powder (purchased from McLean, molecular weight less than 3000) and pour it into a beaker, then add 100 milliliters of deionized water, slowly dissolve under the stirring of a magnetic stirrer to obtain a chitosan oligosaccharide solution.

[0055] (2) The beaker containing the chitosan oligosaccharide solution was left to stand for 5 minutes to remove bubbles, to obtain a uniform dark red solution without bubbles.

[0056] (3) Use a pipette to extract about 20 ml of chitosan oligosaccharide solution and transfer it to a plastic circular sample box.

[0057] (4) Transfer the circular sample box containing the chitosan oligosaccharide solution to a vacuum desiccator, and dry it at 70° C. for 72 hours to obtain a chitosan oligosaccharide film sample.

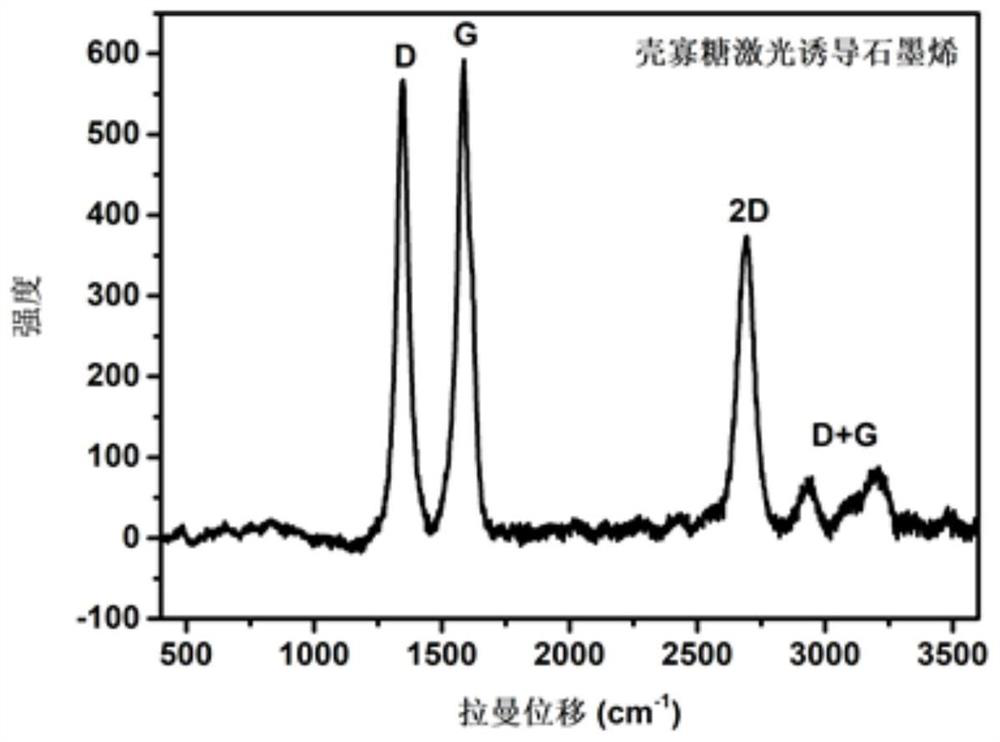

[0058] (5) Use commercial CO 2 The laser induces the reduction of the...

Embodiment 2

[0060] This embodiment provides a preparation method of LIG material, comprising the following steps: adding 1.5 g of cellulose when preparing the chitosan oligosaccharide solution.

[0061] The advantage compared to Example 1 is: (1) oligochitosan can be flame-retardant for cellulose, so that it can be converted into LIG without flame-retardant under normal temperature and pressure air atmosphere, (2) obtain graphene layer number more Less, more conductive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com