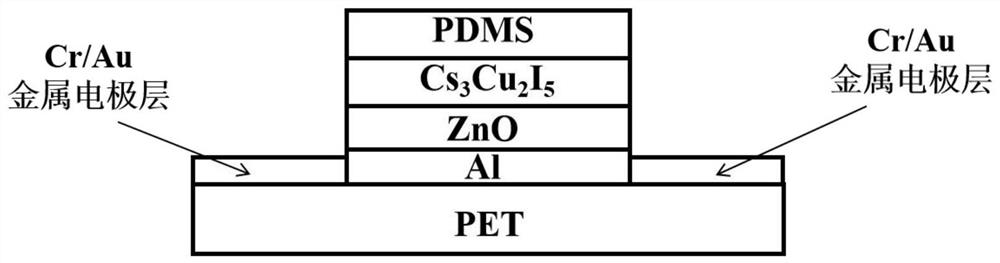

Metal-semiconductor heterojunction flexible ultraviolet photoelectric detector and preparation method thereof

An electrical detector and semiconductor technology, applied in the field of photodetectors, can solve problems such as poor photoelectric performance of photodetectors, and achieve the effects of being conducive to large-scale commercial applications, excellent mechanical flexibility, and improving response detection capabilities.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] Methods of preparation, including:

[0040] S1: Cut the flexible material into a 1cm×1cm square, wash it with acetone: alcohol (volume ratio 1:2), and dry it at 20°C-25°C for 20-25min in a nitrogen environment, then use a gas flow of 60-70sccm, Plasma power is 0.8-0.9W / cm 2 oxygen plasma treatment for 10-15min to obtain a flexible substrate;

[0041] S2: First, a Cr metal electrode with a thickness of 50 nm is vapor-deposited on the surface of the flexible substrate by a vacuum evaporation coating method, and then an Au metal electrode with a thickness of 50 nm is vapor-deposited;

[0042] The vacuum evaporation conditions are: the degree of vacuum is 5×10 -3 Pa, the evaporation rate is

[0043] Al thin films were prepared by spin coating on the surface of flexible substrates at 20°C-22°C and relative humidity 40%;

[0044] The specific steps of spin coating are as follows:

[0045] 1) Vacuum adsorb the flexible substrate on the center of the spinner turntable; ...

Embodiment 1

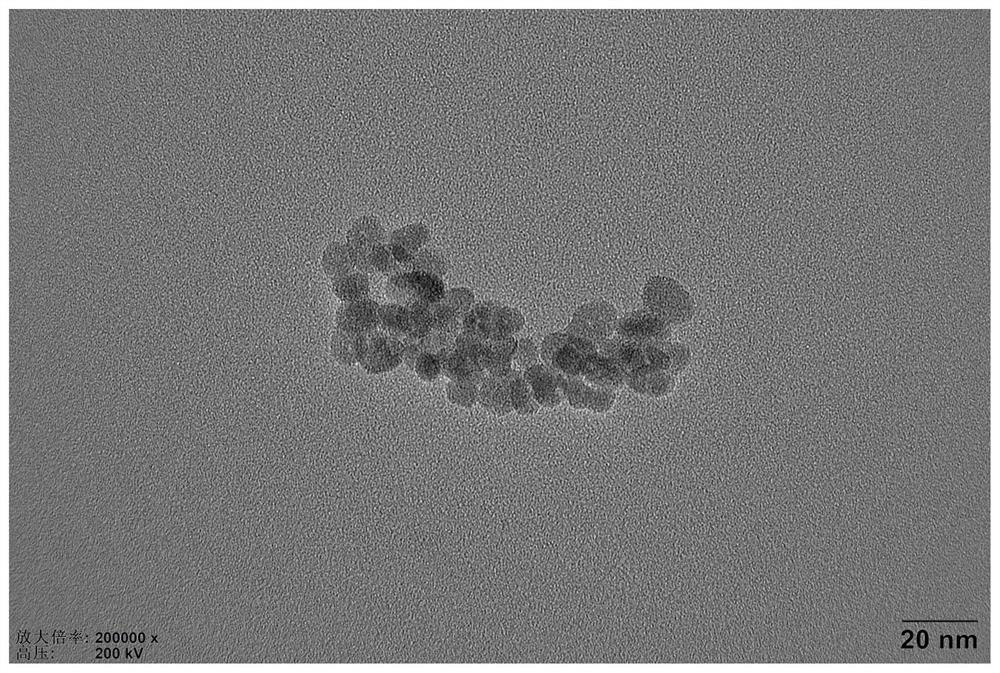

[0069] Example 1, preparation of Al nanocrystals:

[0070] Aluminum chloride (AR, 97%, 0.067 g) was dissolved in mesitylene (HPLC, ≥90.0%, 10 mL; mesitylene was washed with concentrated sulfuric acid until it became colorless, and then washed with deionized water and 5-8 % NaOH solution for continuous washing, then the treated mesitylene solvent was washed with CaH 2 Stir for 10-12 h, use after distillation), stir the mixture at 80-85 °C (200 r / min), and add polyethylene glycol (average Mn4000) and lithium aluminum hydride (1.138 g, 30 mmol; lithium aluminum hydride in Reprecipitate in 10 mL of mesitylene before use to form LiAlH 4 Nanoparticles), the solution was heated to 140 °C and magnetically stirred (200 r / min) under nitrogen atmosphere for 10 h. The solvent was washed several times with anhydrous acetone and centrifuged (6000 r / min, 10-15 min), and finally Al nanoparticles were dispersed in anhydrous acetone solution to prepare a transparent Al NCs solution (0.1 mg / mL...

Embodiment 2

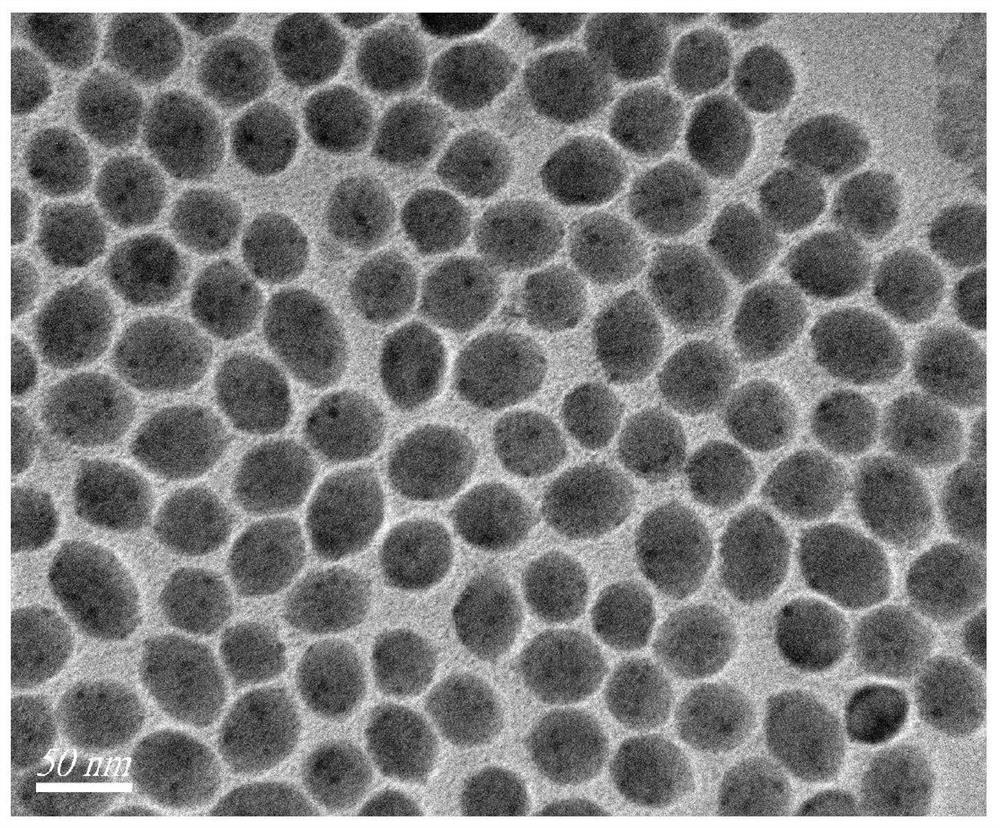

[0071] Example 2, preparation of ZnO quantum dots:

[0072] 2.95 g of zinc acetate dihydrate (AR, 99%) was dissolved in 125 mL of methanol (AR, 99.5%) at 60°C, and potassium hydroxide (GR, ≥99.7%, 1.48 g)-methanol was mixed with vigorous stirring (65 mL) solution was added to the zinc acetate dihydrate solution. Continuous stirring at 60 °C for 3 h, the solution changed from translucent to a milky white suspension, and nanoparticles began to precipitate. At this time, the pellet was obtained by centrifugation (5000-6000 r / min, 5-8 min). Subsequently, the precipitate was washed several times with methanol and centrifuged again (5000 r / min, 5 min). Finally, the ZnO nanocrystals were dispersed in ethanol solution to prepare a white transparent ZnO suspension (2 mg / mL), which was subjected to transmission electron microscopy (TEM) ) as shown in figure 2 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com