Polymer coating liquid for self-cleaning glass and preparation method of polymer coating liquid

A polymer, self-cleaning technology, applied in coatings, polyurea/polyurethane coatings, etc., can solve the problems of difficulty in maintaining the mechanical stability of superhydrophobic coatings, loss of the original value of glass, damage to surface texture, etc. Uniform, strong adhesion, not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation of the silicone polyurethane resin is a conventional polyurethane preparation process, for example, it can be carried out according to the following process: adding a polyol to the reaction kettle and diluting it with DMF, adding half of the isocyanate, heating the temperature to 80 ° C and stirring for 1 hour, and then continuing to add DMF to the appropriate viscosity, adding silicone diol and stirring for half an hour, then adding the remaining isocyanate, reacting at 80 ° C until the system is viscous, and finally capping with methanol, adding DMF to adjust the solid content to 30%.

[0033] Wherein, the organosilicon diol is prepared by alcohol protection of diethanolamine, followed by chlorine substitution reaction with γ-chloropropyltrimethoxysilane

[0034] At present, the silica sol is usually sprayed directly on the surface of the glass substrate to form a coating, but the durability of the coating is poor. The polymer emulsion can effectively...

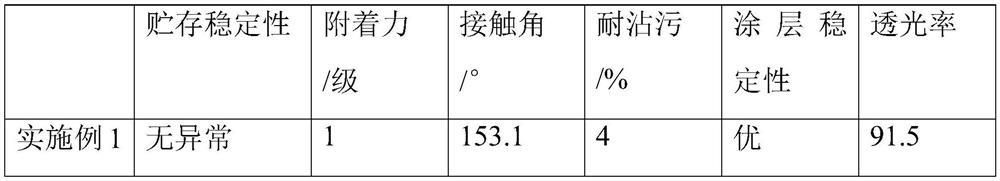

Embodiment 1

[0036] 1 part of high stability silica sol, 5 parts of silicone polyurethane resin and 3 parts of ethanol were mixed together under high speed stirring, then 0.1 part of gamma-glycidyl ether oxyoctyltrimethoxysilane and 2 parts of adjuvant were added Stir well.

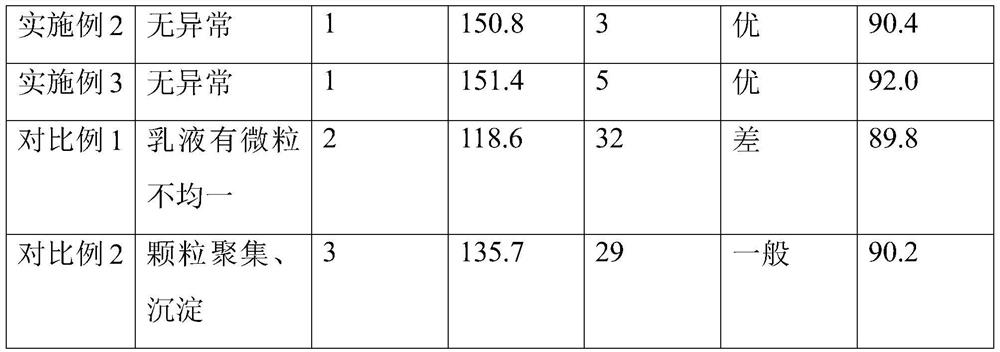

Embodiment 2

[0038] 2 parts of high stability silica sol, 7 parts of silicone polyurethane resin and 3 parts of ethanol were mixed together under high speed stirring, then 0.3 parts of gamma-glycidyl ether oxyoctyltrimethoxysilane and 2 parts of adjuvants were added Stir well.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com