Method for producing water-soluble epoxide by using sodium bromide through photoelectrode under simulated natural light

An epoxy, water-soluble technology, applied in electrolytic organic production, electrolytic components, electrolytic process, etc., can solve the problems of low-efficiency electrodes, toxic reagents, high energy consumption, etc., achieve high selectivity and avoid side reactions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

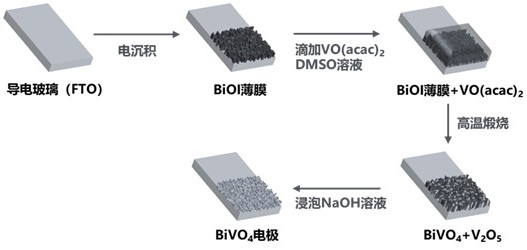

[0042] Example 1 Preparation of Photoelectrode

[0043] The photoelectrode preparation method is as follows, and its schematic flow chart is as follows figure 1 shown.

[0044] a. Preparation of electrodeposited BiOI films

[0045] 0.04M2Bi (NO 3 ) 3 ·5H 2 O Add 50 mL of HNO freshly prepared pH 1.7 3 in aqueous solution. After transfer to an ice-water bath and sonicated for 5 min, it became a milky white solution. 0.4M KI was added to the solution, and after continued sonication in an ice-water bath for 5 minutes, the solution became clear and transparent orange-yellow. 20 mL of 0.23M p-benzoquinone solution in absolute ethanol was added, mixed and sonicated in an ice-water bath for 5 minutes to form a colorless and transparent reddish-brown electroplating solution. A typical three-electrode system consisting of a clean and dry FTO working electrode, a saturated Ag / AgCl reference electrode and a Pt wire counter electrode was used and electrodeposited at room temperatur...

Embodiment 2

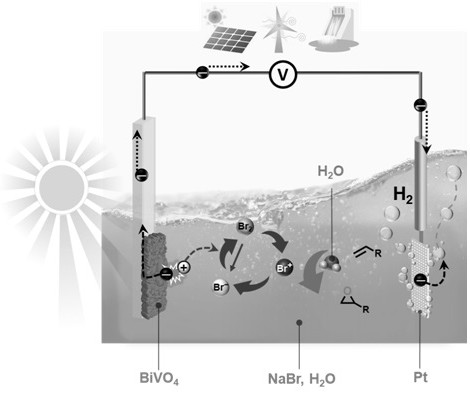

[0048] Embodiment 2 photoelectrode utilizes sodium bromide to produce water-soluble epoxide

[0049] figure 2 It is a schematic diagram of the production system of water-soluble epoxide using sodium bromide with photoelectrode. A method for utilizing sodium bromide to produce water-soluble epoxide with photoelectrode under simulated natural light, comprising the following steps:

[0050] A, take material and prepare reaction solution: get molar concentration and be that the sodium bromide of 20mM, 20mM sodium styrene sulfonate volume percent are that the water of 20% acetonitrile adds in mixer and mixes; Continuous stirring in the pool;

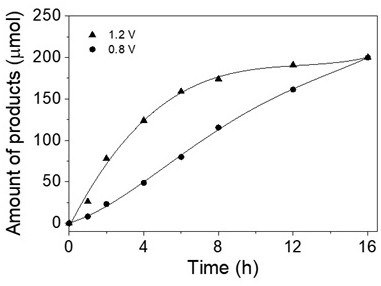

[0051] b. Photocatalytic oxidation: The photoelectrochemical cell was under magnetic stirring and measured using an electrochemical analyzer. Using BiVO prepared in Example 1 4 The electrode was used as the working electrode, the platinum mesh was used as the counter electrode, and the saturated Ag / AgCl was used as the reference electrod...

Embodiment 3

[0052] Embodiment 3 photoelectrode utilizes sodium bromide to produce water-soluble epoxide

[0053] A method for utilizing sodium bromide to produce water-soluble epoxide with photoelectrode under simulated natural light, comprising the following steps:

[0054] A, take material and prepare reaction solution: getting molar concentration is 20mM sodium bromide, 20mM sodium methallyl sulfonate, and the volume percent is that the water of 20% acetonitrile adds in mixer and mixes; Continuous stirring in the quartz photoelectrochemical cell;

[0055] b. Photocatalytic oxidation: The photoelectrochemical cell was under magnetic stirring and measured using an electrochemical analyzer. Using BiVO prepared in Example 1 4 The electrode was used as the working electrode, the platinum mesh was used as the counter electrode, and the saturated Ag / AgCl was used as the reference electrode. Illumination from the back of the working electrode by simulating natural light. With 0.8V relative...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com