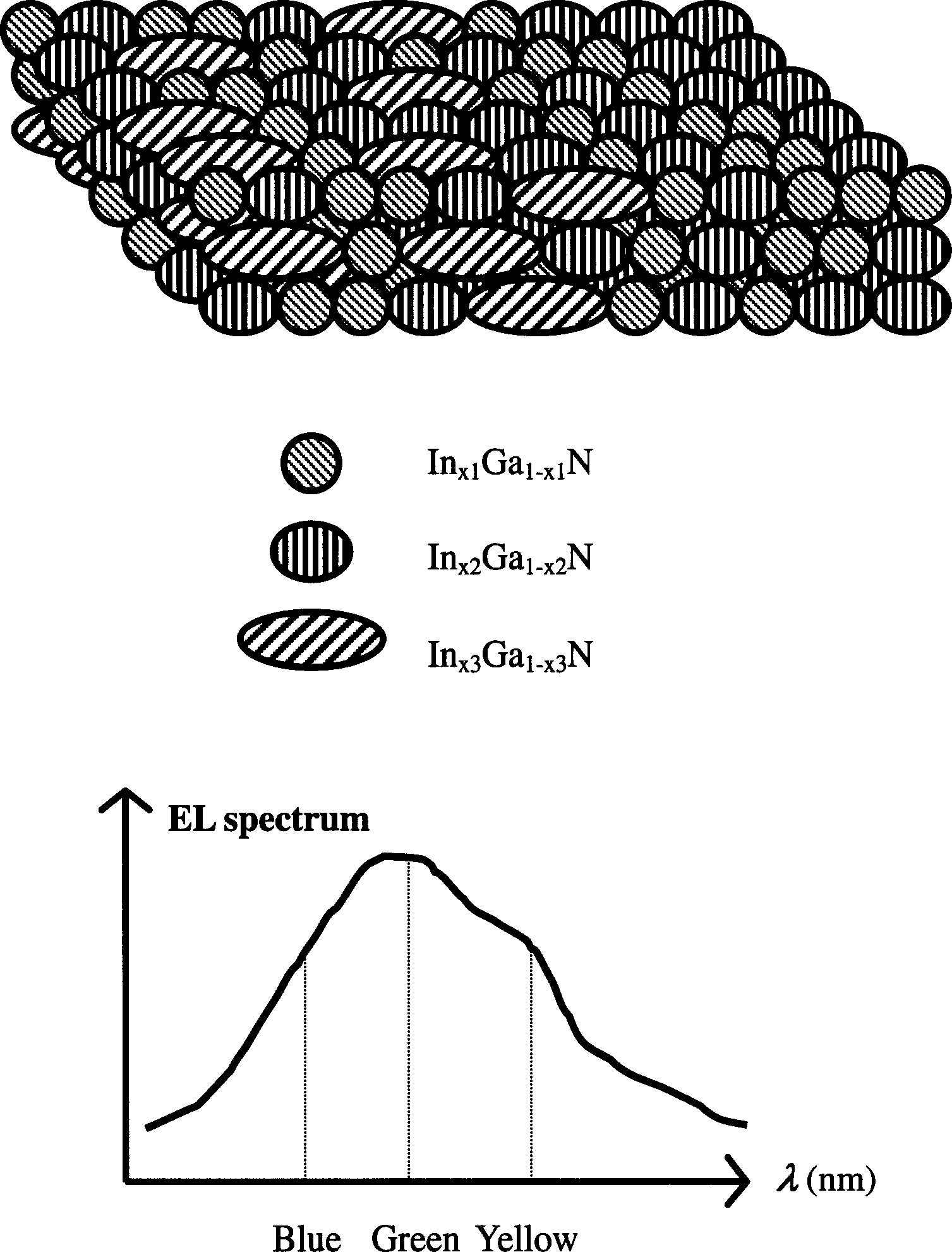

Quanta dot active region structure of broad spectrum white light LED and epitaxial growth method thereof

A quantum dot active region, epitaxial growth technology, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as poor white light color rendering index, high device operating voltage, and no LED materials and devices involved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

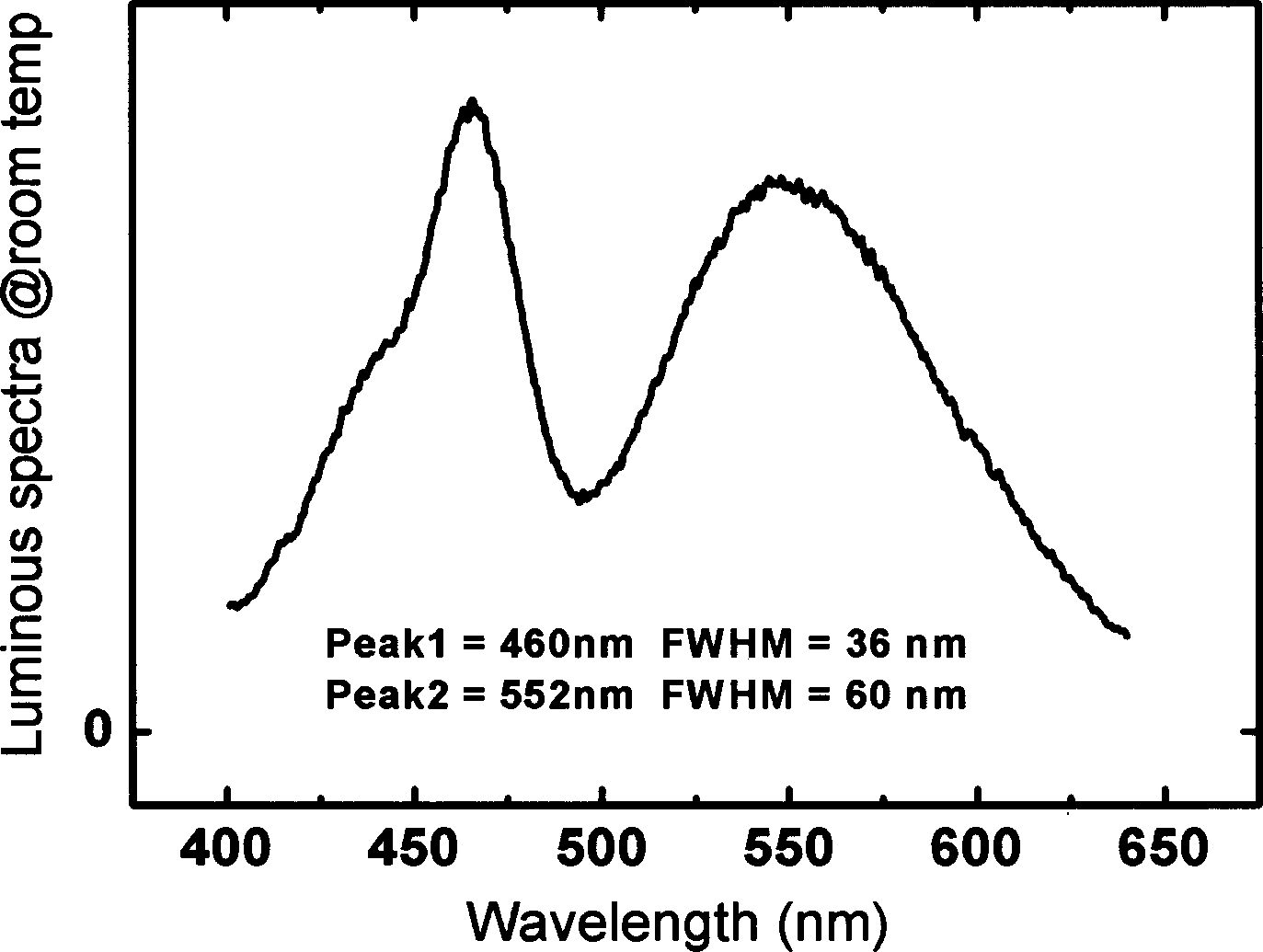

[0075] The MOCVD epitaxial growth of LED materials containing a single type of indium gallium nitride / gallium nitride (InGaN / GaN) quantum dot buried structure in the active area is carried out to achieve wide-spectrum white light. Its extension sequence is as Figure 4 Shown: sapphire substrate 1, GaN buffer layer 2 (thickness about 80nm-100nm), n-type GaN bulk material and ohmic contact layer 3 (thickness about 4000nm), n-type AlGaN barrier layer and GaN isolation layer 4 (thickness About 50nm), InGaN quantum dot active region 5 (thickness 20nm-70nm), GaN isolation layer and p-type AlGaN barrier layer 6 (thickness about 40nm), p-type GaN ohmic contact layer 7 (thickness 150nm-250nm).

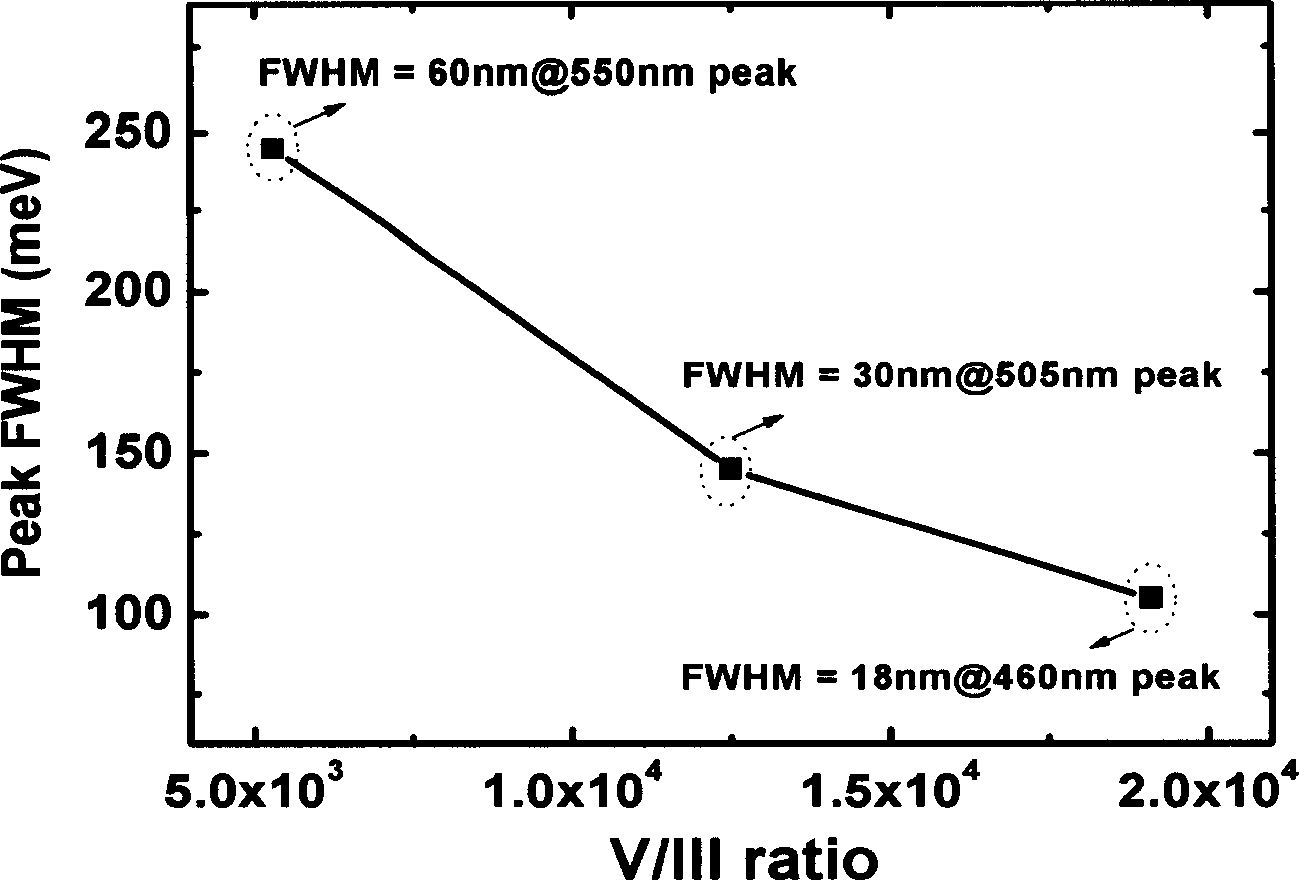

[0076] Among them: the Al% of the n-type and p-type AlGaN barrier layers is 8%-12%; the average In composition of the quantum dot active area and the quantum dot nucleation / agglomeration rate are jointly controlled by TEGa, TMIn flow rate and substrate temperature. When TEGa flow rate is 87sccm (10...

Embodiment 2

[0078] Perform MOCVD epitaxial growth of LED materials containing a single type of indium gallium nitride / indium gallium nitride (InGaN / InGaN) quantum dot buried structure in the active area to achieve wide-spectrum white light. Its extension sequence is as Figure 6 Shown: sapphire substrate 1, GaN buffer layer 2 (thickness about 80nm-100nm), n-type GaN bulk material and ohmic contact layer 3 (thickness about 4000nm), n-type AlGaN barrier layer and GaN isolation layer 4 (thickness About 50nm), InGaN barrier region 5 (In%-10%, thickness 10nm-15nm), InGaN quantum dot active region 6 (thickness about 20nm~70nm), GaN barrier region and isolation layer 7 (thickness about 10nm-15nm) ), a p-type AlGaN barrier layer 8 (with a thickness of about 40 nm), and a p-type GaN ohmic contact layer 9 (with a thickness of 150 nm to 250 nm).

[0079] Among them: the Al% of the n-type and p-type AlGaN barrier layers is 8%-12%; the average In composition of the quantum dot active area and the quantum ...

Embodiment 3

[0081] Conduct MOCVD epitaxial growth of LED materials with multiple types of indium gallium nitride / gallium nitride (InGaN / GaN) quantum dot buried structures and indium gallium nitride / gallium nitride (InGaN / GaN) quantum well layers cascaded in the active area, Achieve wide-spectrum white light. Its extension sequence is as Figure 8 Shown: sapphire substrate 1, GaN buffer layer 2 (thickness about 80nm-100nm), n-type GaN bulk material and ohmic contact layer 3 (thickness about 4000nm), n-type AlGaN barrier layer and GaN isolation layer 4 (thickness About 50nm), InGaN / GaN multiple quantum well active region 5 (repetition period is 3, InGaN quantum well thickness is about 2nm, GaN barrier region thickness is about 10nm), InGaN quantum dot light emitting region 6 (thickness is about 20nm~70nm), GaN isolation layer 7 (thickness of about 10 nm-15 nm), p-type AlGaN barrier layer 8 (thickness of about 40 nm), p-type GaN ohmic contact layer 9 (thickness of 150 nm to 250 nm).

[0082] Amon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com