High solidness low viscosity nano composite polyester resin and method of preparation

A high-solid, low-viscosity, polyester resin technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of difficult preparation of high-solid nanocomposite resins, difficult removal of modifiers, and increased viscosity of the system. Effects of reduced hydrogen bonding, high silica concentration, and improved wear resistance of coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

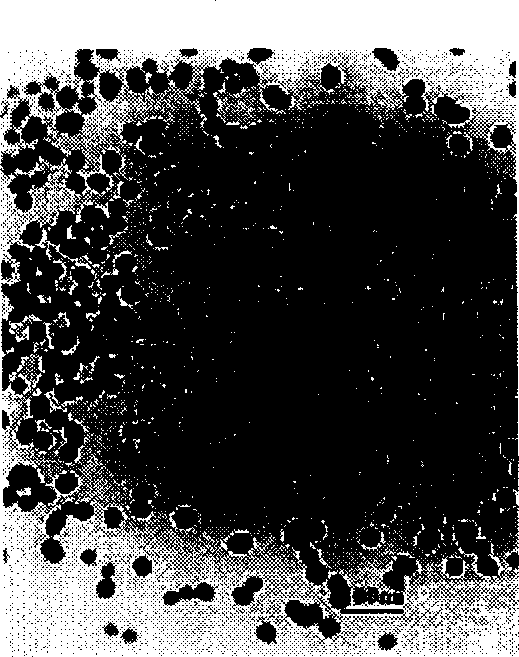

[0021] In a 500ml four-neck flask equipped with a thermometer, a condenser, a nitrogen port, and a stirrer, add 1.0mol of undecanedibasic acid, 1.3mol of 1,4-butanediol, 0.7mol of polyethylene glycol with a molecular weight of 200, The silica sol whose nano-silica content accounts for 14% of the total weight of the resin is heated up to 120°C for 30 minutes to remove the solvent in the sol, then heated up to 160-180°C, reacted for 4 hours, slowly cooled to room temperature, and discharged. The nano-silica composite hydroxyl-terminated polyester resin is obtained.

Embodiment 2

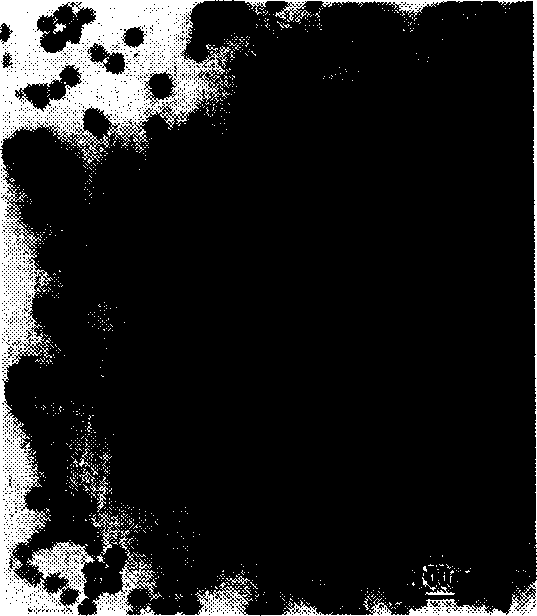

[0023] In a 500ml four-necked flask equipped with a thermometer, a condenser, a nitrogen port, and a stirrer, add 0.3mol of 1,4-cyclohexanedicarboxylic acid, 0.4mol of azelaic acid, 0.3mol of octadecanedioic acid, and 0.3mol of a Diethylene glycol acetal, 0.2mol 2-ethyl-2-propyl-1,3-propanediol, 0.5mol 1,6-hexanediol, 0.1mol trimethylolpropane, nano-silica content accounted for the total resin For 6% silica sol by weight, heat up to 120°C for 30 minutes to remove the solvent in the sol, continue to heat up to 160-180°C, react for 5 hours, then heat up to 200-220°C for 1 hour, slowly cool to room temperature, The material is discharged to obtain a nano-silica composite polyester resin.

Embodiment 3

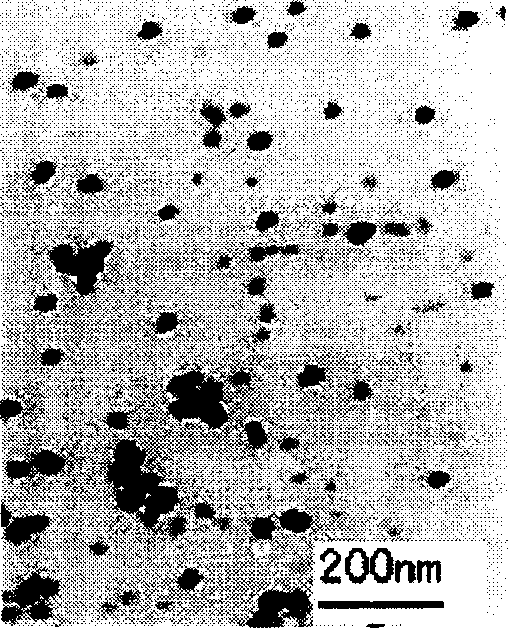

[0025] In a 500ml four-necked flask equipped with a thermometer, a condenser, a nitrogen port, and a stirrer, add 0.2mol of hexahydrophthalic anhydride, 0.3mol of adipic acid, 0.1mol of terephthalic acid, and 0.2mol of isophthalic acid Acid anhydride, 0.2mol 1,4-cyclohexanedicarboxylic acid, 0.6mol 1,4-cyclohexanediol, 0.8mol polyether diol with a molecular weight of 500, and silica sol whose nano-silica content accounts for 1% of the total weight of the resin , heat up to 120°C for 30 minutes to remove the solvent in the sol, continue to heat up to 180-200°C, react for 6 hours, then heat up to 220-240°C for 0.5 hours, slowly cool to room temperature, and discharge to obtain nano-silica Composite hydroxyl-terminated polyester resin is cured at room temperature with PAPI curing agent to form a film at NCO / OH=0.98, and 0.02% of triethylenediamine is added as a catalyst to obtain a polyurethane coating.

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com