Vertical type wide bandgap semiconductor device structure and making method

A wide-bandgap semiconductor and device structure technology, applied in the field of microelectronics, can solve problems such as the inability to meet the needs of high-power device development, and achieve the effects of reducing defect density and lattice mismatch.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

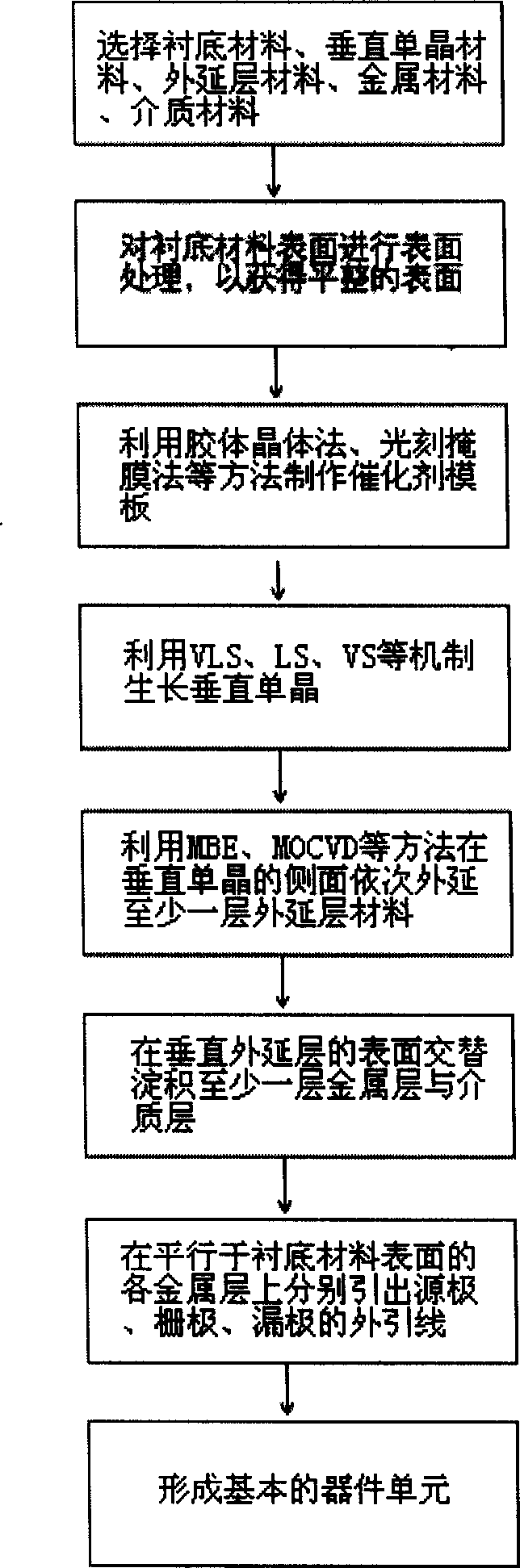

Method used

Image

Examples

example 1

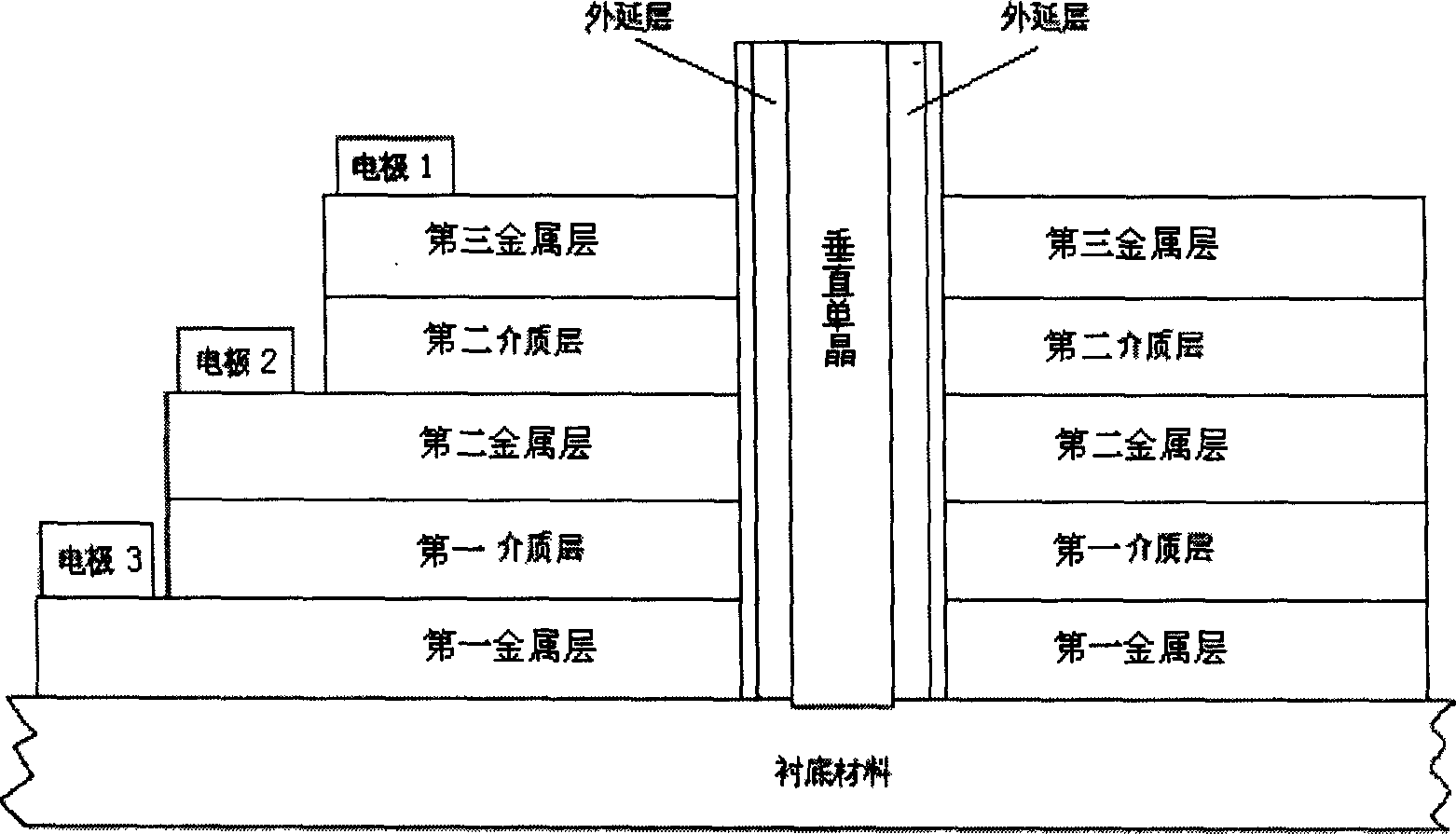

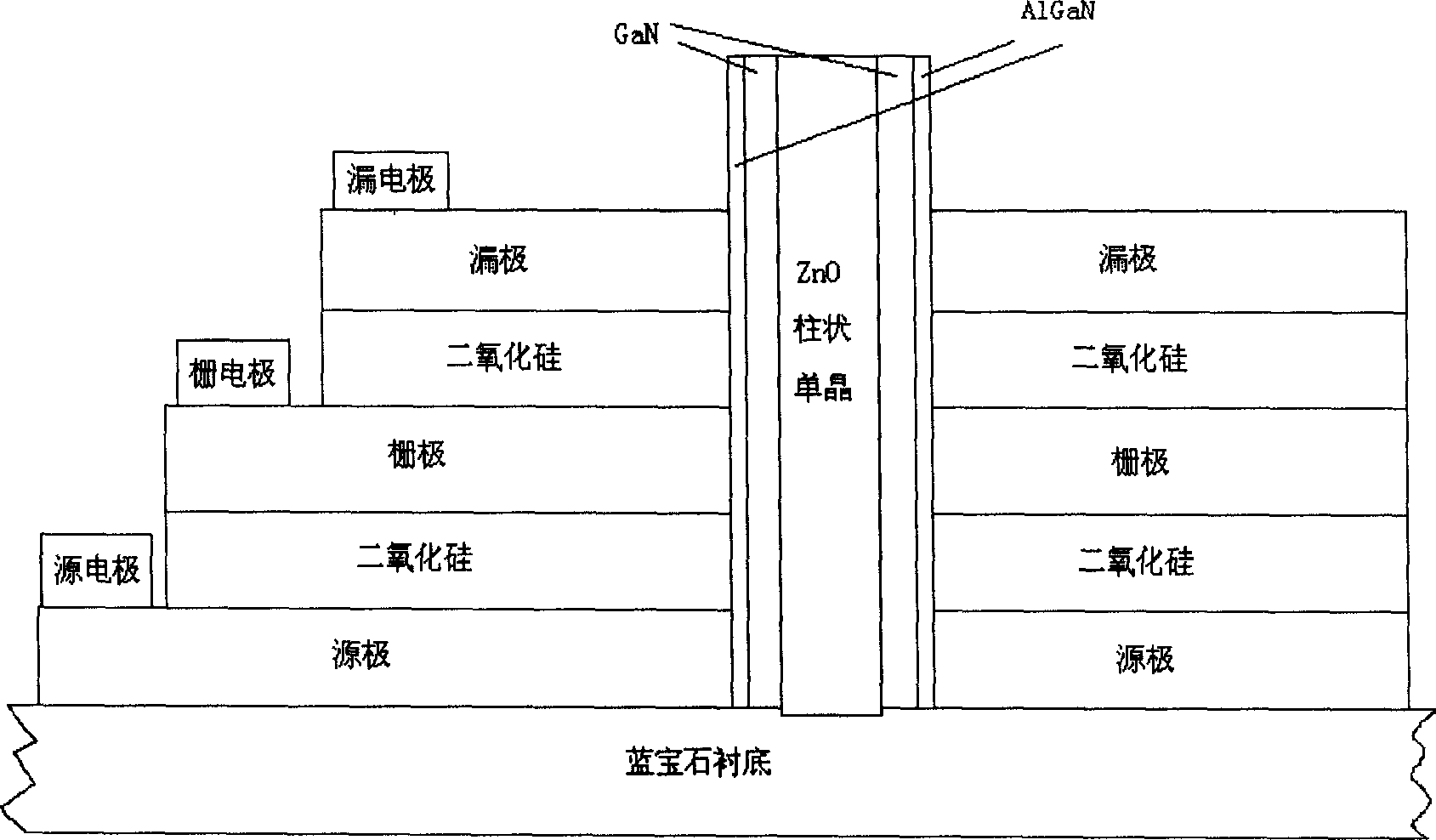

[0039] The invention manufactures a vertical single tube AlGaN / GaN HFET device based on ZnO nano columnar single crystal.

[0040] Epitaxial layer material selection: AlGaN, GaN.

[0041] Vertical single crystal material selection: ZnO.

[0042] Substrate material selection: (2-1-10) crystal plane of single crystal sapphire.

[0043] Metal material selection: Au, Ti / Ag, Al.

[0044] Dielectric material selection: SiO 2 .

[0045] Refer to image 3 , The structure and manufacturing process of the device in this example are as follows:

[0046] 1. Growth of ZnO nano columnar single crystal

[0047] The first step is the fabrication of a single-layer self-assembled submicron ball array.

[0048] Choose sapphire as the substrate. The colloidal crystal method is used to make the sub-micron sphere array, and the selected colloidal crystal is polystyrene sub-micron spheres, and the diameter of the polystyrene spheres is about 895 nm. Firstly, ultrasonically degrade the substrate for 20 m...

example 2

[0070] The invention manufactures a vertical single-tube AlGaN / GaN HFET device based on a ZnO nano-belt single crystal.

[0071] Epitaxial layer material selection: AlGaN, GaN.

[0072] Vertical single crystal material selection: ZnO.

[0073] Substrate material selection: polycrystalline sapphire.

[0074] Metal material selection: Au, Ti / Ag, Al.

[0075] Dielectric material selection: Si 3 N 4 .

[0076] Refer to Figure 4 , The structure and manufacturing process of the device in this example are as follows:

[0077] 1. Growth of ZnO nano-ribbon single crystal

[0078] In this example, the ZnO nano-ribbon single crystal is grown by the VS mechanism, and the selected substrate is a sapphire polycrystalline material. The raw materials used are ZnO powder and 1% Li 2 O powder. First, the raw materials are mixed and placed on the alumina boat in the center of the alumina test tube, and the sapphire polycrystalline substrate material is placed at the downstream position of the alumi...

example 3

[0096] The invention manufactures an air-isolated vertical mesh AlGaN / GaN microwave power device based on an array of ZnO nano-columnar single crystals.

[0097] Epitaxial layer material selection: AlGaN, GaN

[0098] Vertical single crystal material selection: ZnO

[0099] Substrate material selection: n-type doped GaN conductive material;

[0100] Selection of metal materials: Au, Ti / Ag, Al

[0101] Medium material selection: air

[0102] Refer to Figure 5 , The structure and production process of this example are as follows:

[0103] 1. Growth of arrayed ZnO nano columnar single crystals

[0104] The first step is to make a catalyst template

[0105] First, deposit a thin layer of Au catalyst on the GaN substrate by thermal evaporation;

[0106] Then, according to the distribution density of the devices and heat dissipation requirements, design and manufacture the photolithography mask;

[0107] Finally, a layer of photoresist is covered on the surface of the Au catalyst layer,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com