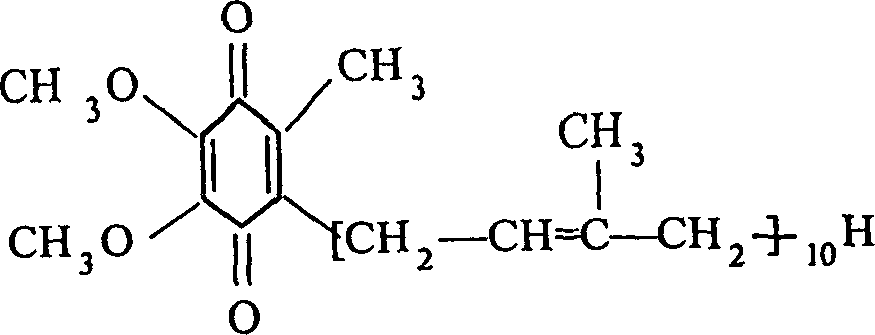

Art for synthesizing acetylide of coenzyme Q10 intermediate

A synthesis process and technology of acetylide, which is applied in the field of synthesis process of coenzyme Q10 intermediate acetylide, can solve problems such as high process cost, use safety problems, environmental pollution, etc., and achieve good safety, easy storage, and low process cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

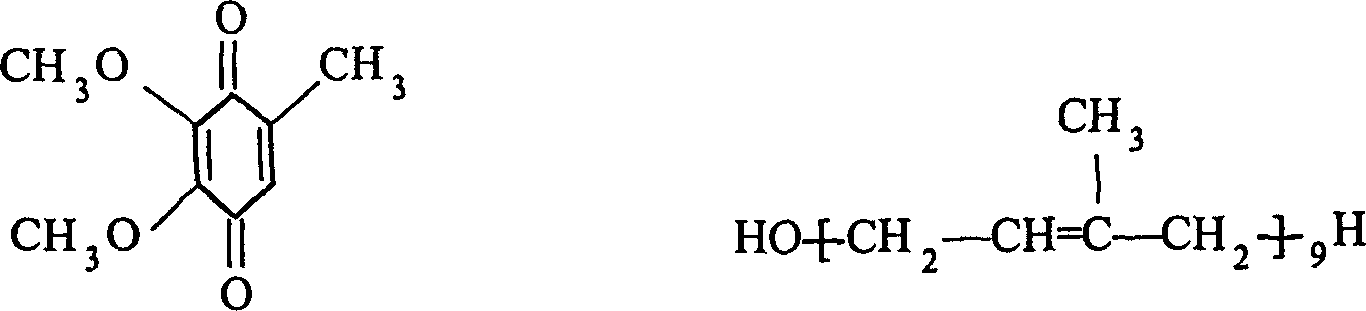

Problems solved by technology

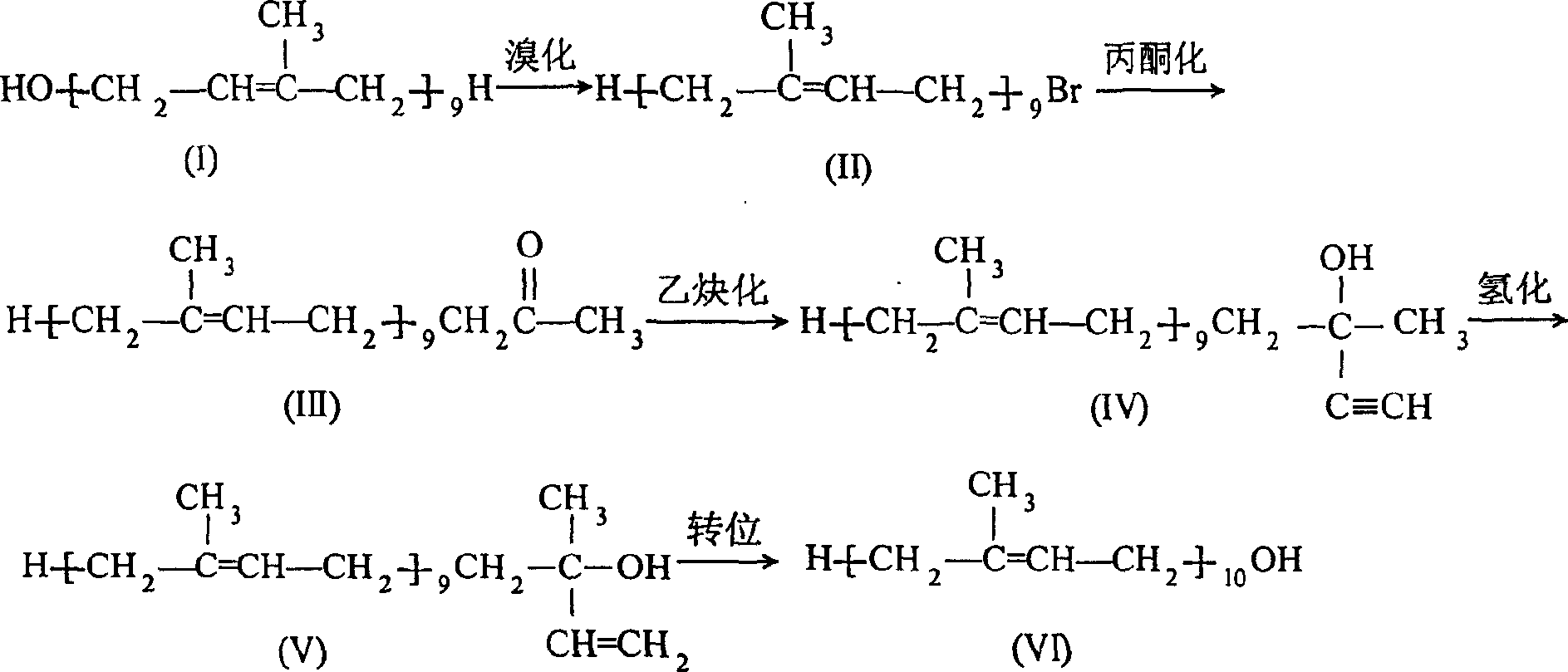

Method used

Image

Examples

Embodiment 1

[0026] Coenzyme Q 10 The synthesis process of the intermediate acetylide is a semi-synthetic method to prepare coenzyme Q 10 In the process, the synthetic technique of obtaining 3-methyl-solanylbutyn-1-alcohol-3 by introducing ethynyl through ethynylation by solanyl acetone is characterized in that: the synthetic technique is that 40 grams of hydrogen Sodium oxide, 400 milliliters of isobutanol and 530 milliliters of toluene are placed in a 2000 milliliter flask equipped with a water separator and a stirrer, heated to reflux under stirring to make it fully react, and about 18 to 20 milliliters of generated water are separated and removed, and the reaction liquid After cooling, feed acetylene gas to react with it, and absorb about 2.5-3 liters of acetylene to obtain acetylene reaction liquid. Add 100 milliliters of solution containing 40 grams of solanylacetone dropwise to the acetylene reaction liquid under stirring conditions at room temperature and react for 5 hours, then a...

Embodiment 2

[0028] Coenzyme Q 10 The synthesis process of the intermediate acetylide is a semi-synthetic method to prepare coenzyme Q 10 In the process, the synthetic technique that obtains 3-methyl-solanylbutyn-1-alcohol-3 by introducing ethynyl through ethynylation by solanyl acetone is characterized in that: the synthetic technique is that 150 grams of hydrogen Potassium oxide, 1200 milliliters of butanol and 1200 milliliters of toluene are placed in a 3000 milliliter flask equipped with a water separator and a stirrer, heated to reflux under stirring to make it fully react, and about 60-64 milliliters of generated water is separated and removed. Enter acetylene gas to react with it, absorb about 8-10 liters of acetylene to obtain acetylene reaction liquid. Add 250 milliliters of solutions containing 100 grams of solanylacetone dropwise to the acetylene reaction solution under stirring at room temperature for 5 hours, then import into a 5000 milliliter beaker filled with 1000 millilit...

Embodiment 3

[0030] Coenzyme Q 10 The synthesis process of the intermediate acetylide is a semi-synthetic method to prepare coenzyme Q 10 In the process, the synthetic technique of obtaining 3-methyl-solanylbutyn-1-alcohol-3 by introducing ethynyl through ethynylation from solanyl acetone is characterized in that: the synthetic technique is that 2.5 kilograms of hydrogen Potassium oxide, 25 liters of isobutanol and 58 liters of toluene are placed in a reaction kettle equipped with a water separator and agitator, heated to reflux to make it fully react, and about 0.85-0.9 liters of generated water are separated and removed, and the reaction liquid is cooled and passed into acetylene The gas reacts with it and absorbs about 125-150 liters of acetylene to obtain an acetylene reaction liquid. Add 5 liters of solution containing 2 kg of solanyl acetone to the acetylene reaction solution under stirring conditions at room temperature and react for 3 hours, then add 20 liters of ice water to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com