Electrochemical supermicro electrode combining method and its super micro combined electrode and preparing process

A technology of combining electrodes and ultra-micro electrodes, which is applied in the fields of biosensors and electro-analytical chemistry, can solve problems such as the inability of composite micro-electrodes to adapt, and achieve the effects of easy control of fabrication conditions, reduced disturbance and good stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

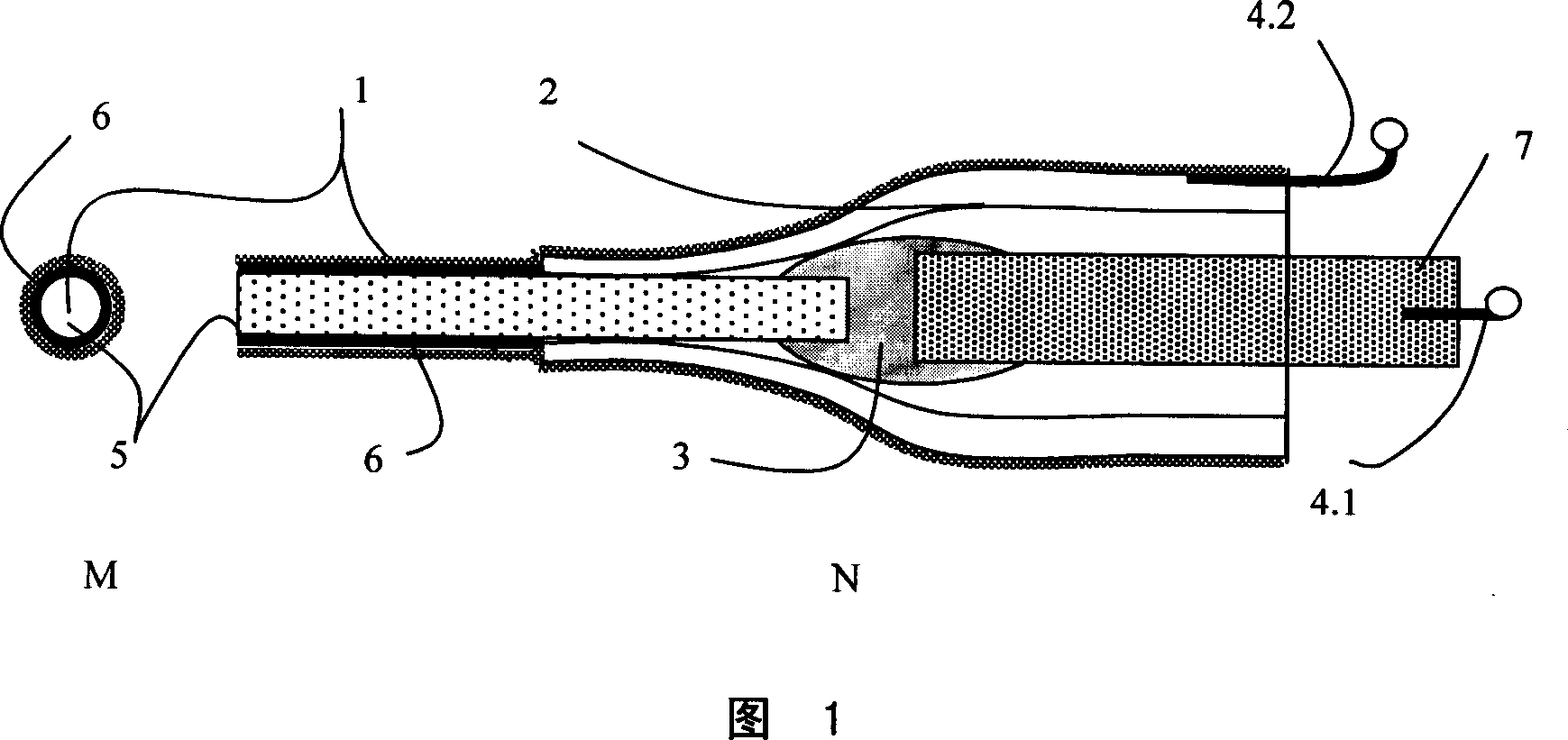

[0049] Embodiment 1: carbon fiber / gold (CF / Au) ultrafine composite electrode

[0050] In this embodiment, carbon fiber electrodes and gold are selected as the combination of the two electrodes, and ethanol and double distilled water are used for ultrasonic cleaning; the conductive adhesive is silver conductive adhesive; the insulating layer is formed by polymerization. The specific production process is as follows: first place the carbon fiber electrode in acetone to reflux for 8 hours, then ultrasonically clean it with ethanol and double distilled water, cut off a 3cm length after complete drying, and then bond it to the end of a 0.1mm copper wire with silver conductive adhesive , placed in a glass capillary of 1.0mm, the carbon fiber electrode was sealed in the glass capillary on the glass capillary puller, and the copper wire exposed at the other end of the glass capillary was sealed and fixed with epoxy resin; then the carbon fiber electrode was immersed in phenol and In...

Embodiment 2

[0052] Embodiment 2: gold / platinum (Au / Pt) ultramicro combined electrode

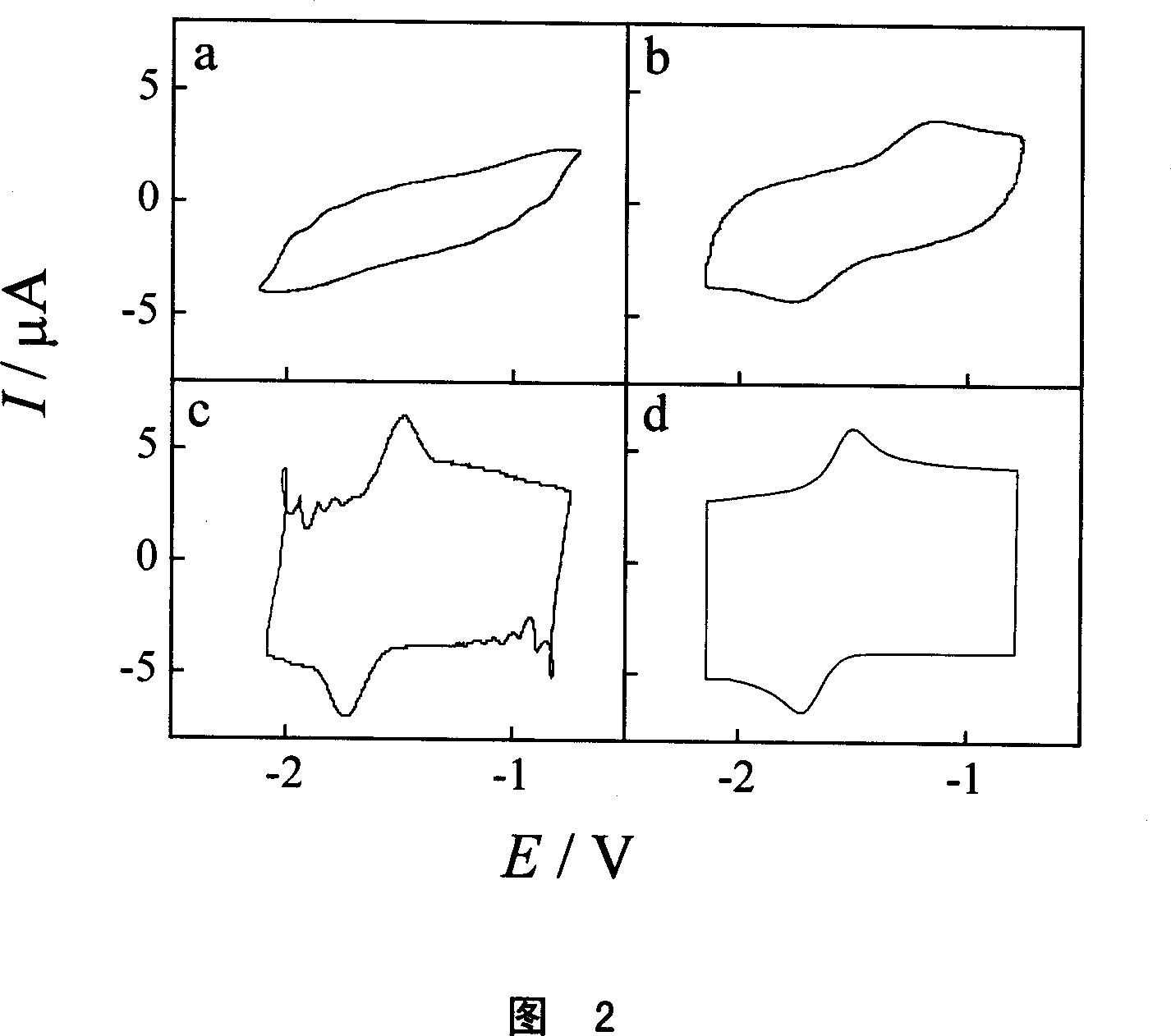

[0053] The preparation process of gold / platinum (Au / Pt) ultrafine composite electrode is similar to that of Example 1. After confirming the various materials and methods used, at first the gold wire with a diameter of 5nm is cleaned in nitric acid and double distilled water, dried and used The conductive adhesive is bonded to the copper wire, placed in a capillary to draw and seal, and the surface of the gold wire is coated with insulating varnish. After drying, an insulating layer with a thickness of 120nm is obtained, and then a layer of 50nm thick platinum is sputtered on the outside of the insulating layer. , using a copper wire to lead out as an alignment / quasi-reference counter electrode, and finally, the front end of the gold electrode coated with a platinum layer and an insulating layer is cut vertically to obtain a gold / platinum (Au / Pt) ultramicro composite electrode. Using the same treatment m...

Embodiment 3

[0055] Embodiment 3: carbon fiber / platinum (CF / Pt) ultramicro combined electrode;

[0056] The cleaning treatment of the carbon fiber is the same as that of Example 1. A layer of epoxy resin is uniformly coated on the clean carbon fiber surface, and the thickness of about 450nm is about 450nm after complete drying. A layer of 50nm thick platinum is sputtered on the epoxy surface, and a copper wire is used to draw it as To align / quasi-reference the counter electrode, finally, the front end of the carbon fiber electrode coated with the platinum layer and the epoxy insulating layer is cut vertically to obtain a carbon fiber / platinum (CF / Pt) ultramicro composite electrode. Using the same treatment method as above, after the insulating layer is formed on the surface of the carbon fiber electrode, the front end of the electrode is cut off directly, and the platinum layer is no longer sputtered, that is, the carbon fiber disk electrode is obtained.

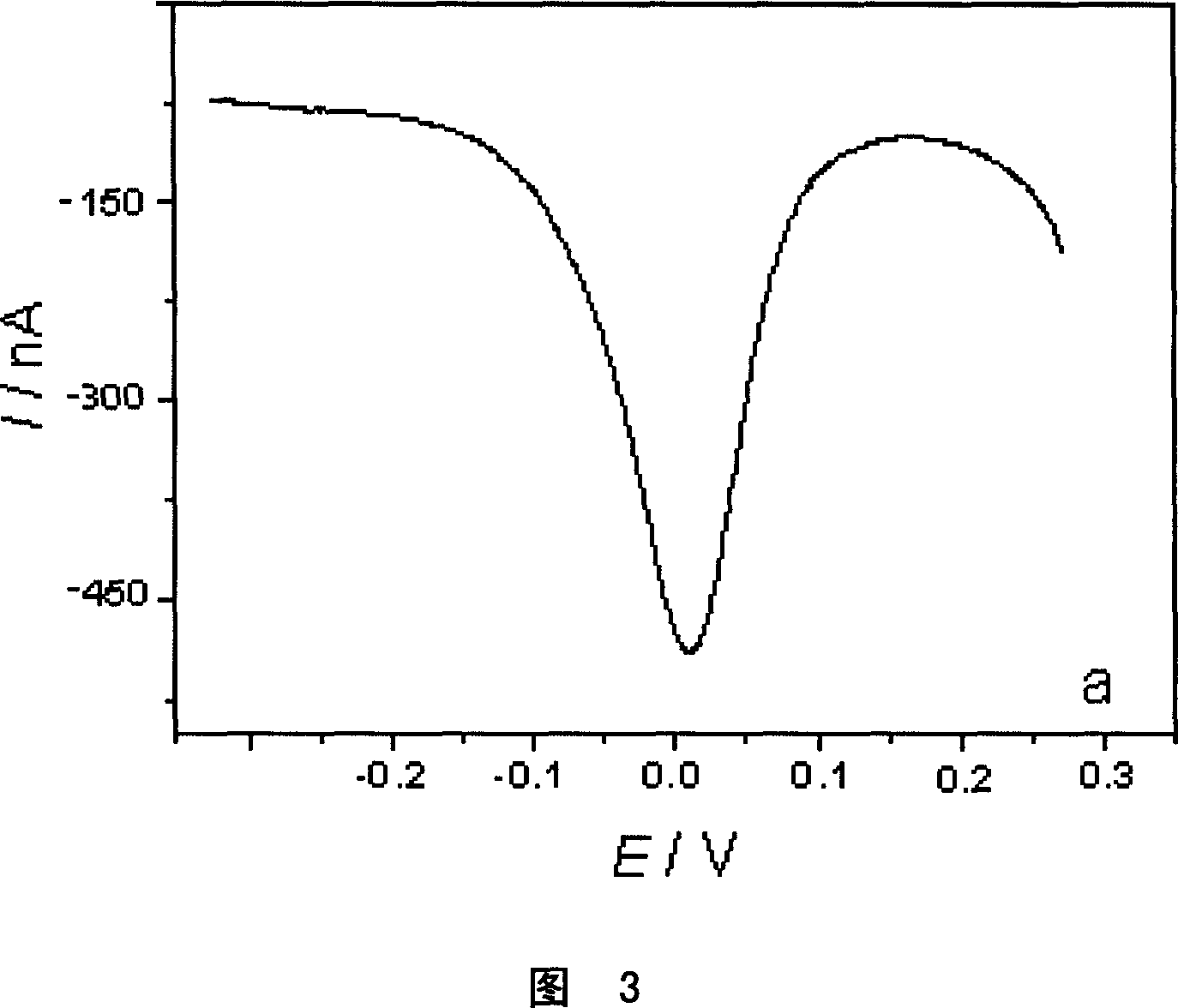

[0057]The carbon fiber / platinum (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com