Low-smoke halogen-free combustion-preventing cable insulation and jacket material for nuclear power plant

A technology for flame retardant cables and nuclear power plants, which can be used in insulated conductors, insulated cables, organic insulators, etc., and can solve the problems of low flame retardant efficiency of flame retardants, deterioration of mechanical properties and process extrusion performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Step 1. Ingredients and high-speed mixing

[0038] Get ethylene-vinyl acetate copolymer 70kg, maleic anhydride grafted polyethylene 30kg, aluminum hydroxide 90kg, tetrakis-(3,5-di-tert-butyl-4-hydroxyphenylpropionic acid) pentaerythritol ester 3kg, phosphorous acid- Dioctyl benzene 1kg, tris (2,4-di-tert-butylphenyl) phosphite 2kg, triallyl isocyanurate 2kg, magnesium stearate, zinc stearate or calcium stearate 2kg, di 1kg of methyl silicone oil and appropriate amount of pigment are placed in a high-speed mixer and mixed at a high speed to prepare a mixture.

[0039] Step 2. Extrusion, plasticization and granulation

[0040] Put the mixture obtained in step 1 into co-rotating twin-screw extruders for plasticizing and granulating.

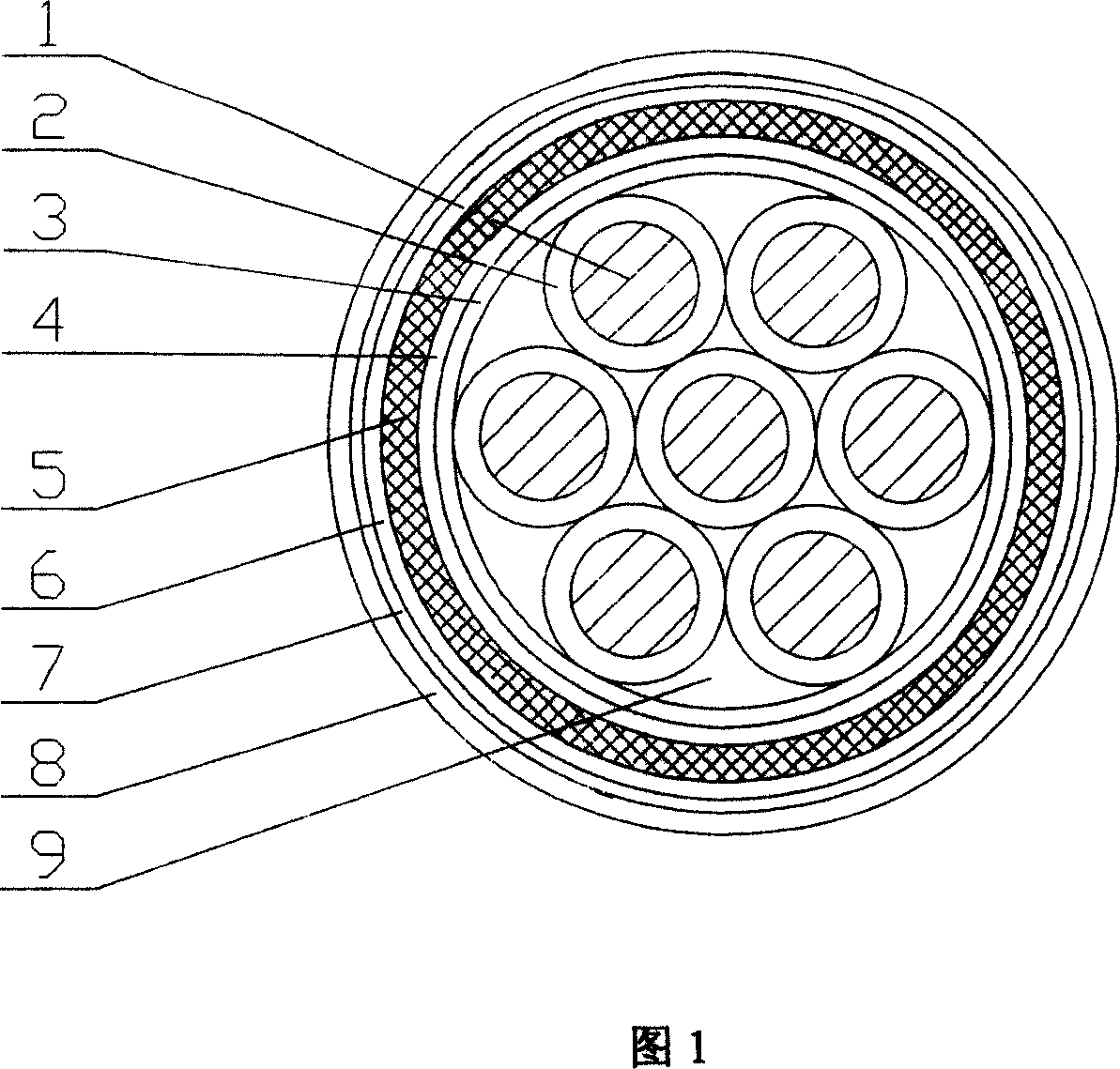

[0041] Step 3. Extrude the pellets obtained in Step 2 together with other materials to form a cable.

[0042] Step 4, subjecting the cables obtained in Step 3 to cross-linking by electron ray irradiation to obtain Class 1E K1 cables for nu...

Embodiment 2

[0043] Embodiment 2: the difference between this embodiment and embodiment 1 is only the ingredients of step one, and all the other are the same as embodiment 1.

[0044] Step 1. Ingredients and high-speed mixing

[0045] Get silicone resin 90kg, maleic anhydride grafted ethylene-vinyl acetate copolymer 10kg, magnesium hydroxide 150kg, 1,3,5 trimethyl-2,4,6-three (3,5-di-tert-butyl-4 -Hydroxybenzyl)benzene 0.3kg, phosphite-benzenedioctyl 2kg, tris(2,4-di-tert-butylphenyl)phosphite 3kg, 1,1,1-trimethylol propene trimethyl 3kg of acrylate, silicone resin, phenylene silica gel or phenolic resin, 1kg of magnesium stearate, 2kg of hydroxyl silicone oil and appropriate amount of pigment are placed in a high-speed mixer and mixed at high speed to prepare a mixture.

Embodiment 3

[0046] Embodiment 3: the difference between this embodiment and embodiment 1 only lies in the batching of step 1, and all the other are the same as embodiment 1.

[0047] Step 1. Ingredients and high-speed mixing

[0048]Get 80kg of silicone resin, 20kg of amide grafted ethylene-vinyl acetate copolymer, 120kg of hydrated silica, 1kg of 4,4'thiobis(6-tert-butyl-3-methylphenol), phosphorous acid-benzenedioctyl Ester 1.5, Tris(2,4-di-tert-butylphenyl)phosphite 1.5kg, 1,1,1-Trimethylolpropene trimethacrylate 2.5kg, Zinc stearate 1.5kg, Hydroxy silicone oil 1.5kg and an appropriate amount of pigment are placed in a high-speed mixer and mixed at a high speed to prepare a mixture.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com