Process and apparatus for waste water treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

Preparation of Nitrification and Denitrification Bacteria Mixture

[0112] Bacteria mixtures useful in nitrification and denitrification were prepared by mixing bacterial mixtures containing various bacterial strains known to nitrify and denitrify.

[0113] For nitrification, a mixture of Enterobacter Sakazaki(ATCC 29544), Bacillus coagulans (ATCC7050), Bacillus subtillis (ATCC 6051), Bacillus subtillis (ATCC 6051), Bacillus megatarium (ATCC7052), Bacillus licheniformis (ATCC14580), Bacillus cerus (ATCC4513) and Bacillus pasytereurii (ATCC 11859) was used. For nitrification, the bacteria were not easy to identify, and include Nitrobacter and Nitrocococcus spp obtained from Cape Cod Biochemicals, 21 Commerce Road, Bourne, Mass.

[0114] Bacterial growth media was prepared in 1 liter batches by dissolving 20 g Bacto Tryptose, 2 g Bacto Dextrose,(Difco Laboratories, Detroit, Mich.), 5 g sodium chloride, and 2.5 g disodium phosphate (Sigma-Aldrich Corp., St. Louis, Mo., U.S.A.) in 1 liter of ...

example 2

Preparation of Carbon Nutrient Mixtures

[0115] Carbon mixtures that are non-flammable, have low viscosity and are readily pumpable liquids, and stable to premature microbial growth were prepared by adding to 100 ml of deionized water, 50 g Maltrin M250 (Grain Processing Corporation, Muscatine, Iowa, U.S.A.), dissolving the solids, and adding 10 ml of methanol (Sigma-Aldrich). In addition to the carbon sources, other micronutrients generally used for growth of bacteria, and described in Handbook of Microbiological Media by R. N. Atlas, CRC Press, Cleveland, Ohio and Media Formulations described in the ATCC catalog , ATCC 12301 Park Lane Drive, Rockville, Ma., were added in the generally recommended quantities. The carbon and nutrient mixtures were found to be stable, as measured by unwanted premature growth for over 4 weeks.

[0116] The bacterial mixtures and carbon / nutrient mixtures were tested for viability using solutions made up of ammonium chloride for ammonia conversion, and sod...

example 3

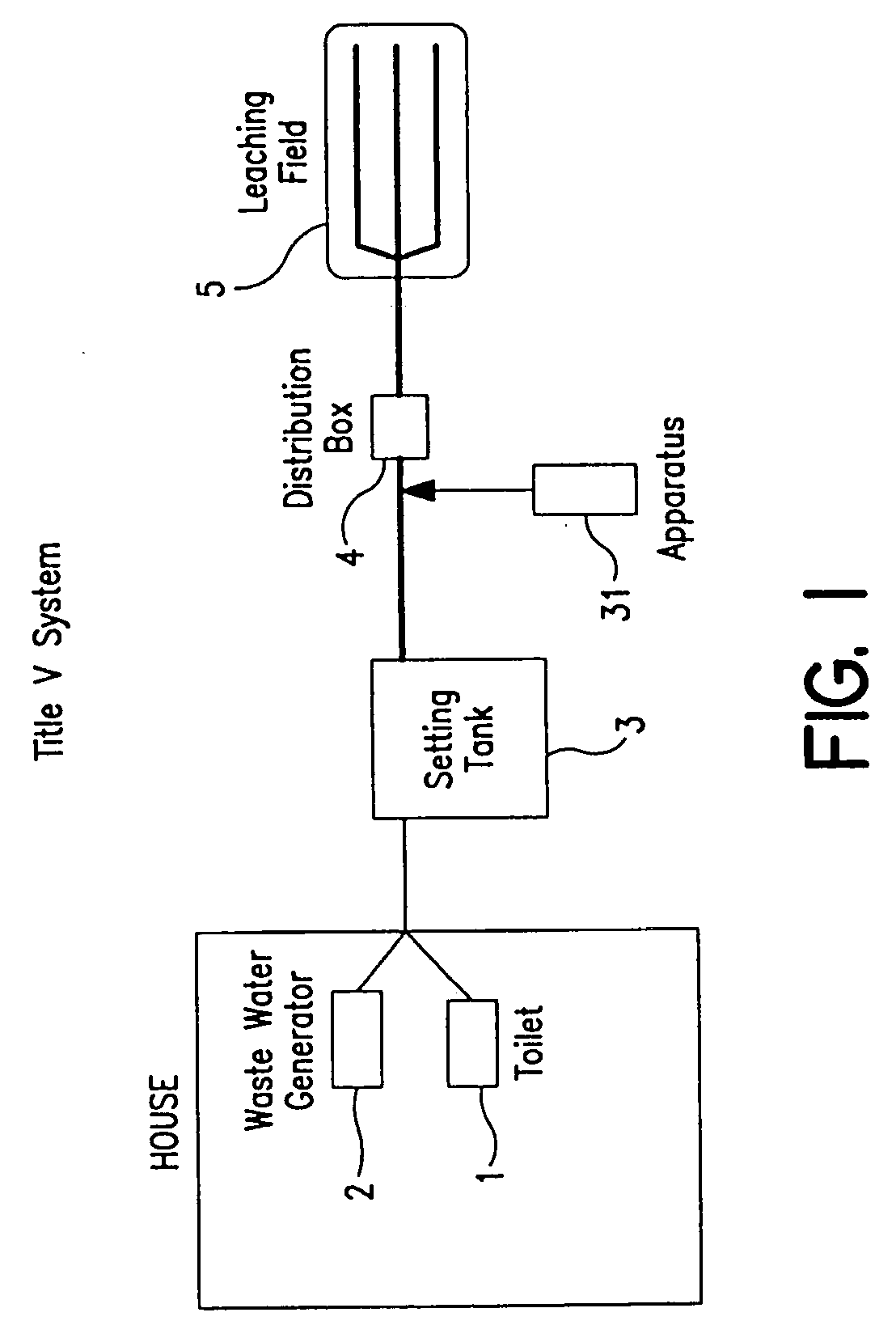

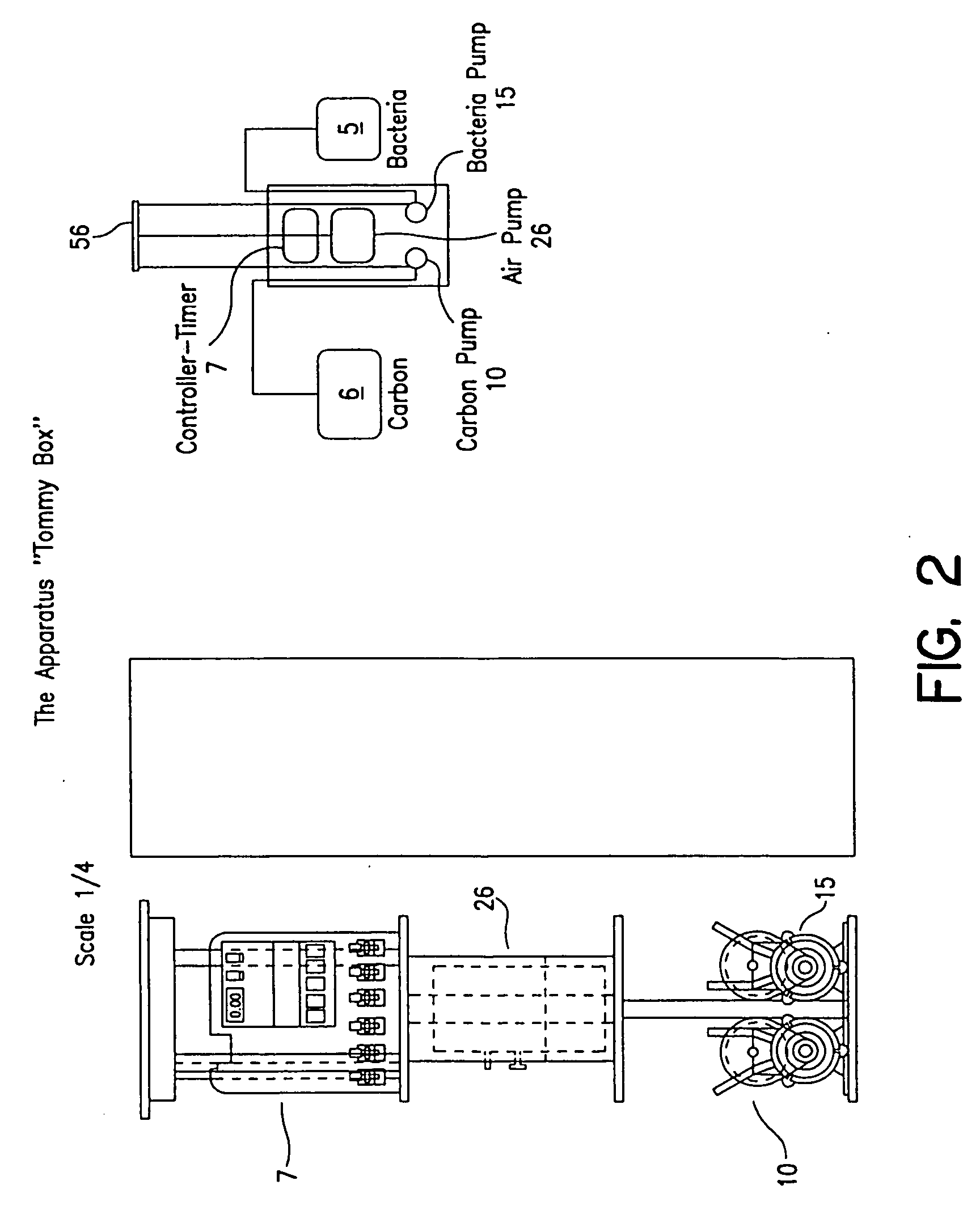

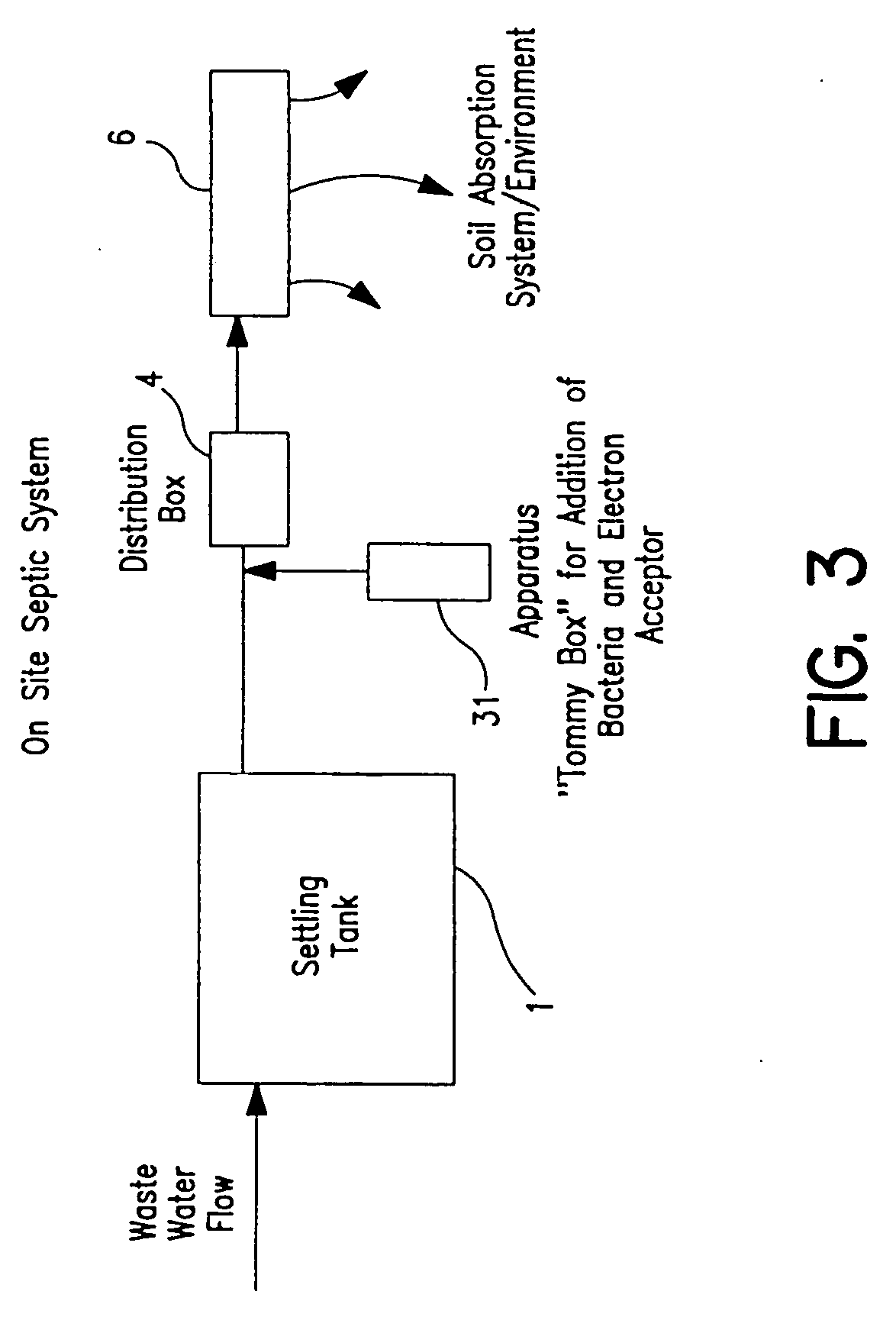

[0119] The bacterial and carbon / nutrient mixtures were then tested in a field test in a system as described in FIG. 2 and FIG. 3, in a sewage treatment testing facility. The waste water exciting the settling tank had 36 ppm nitrate, and was flowing at a rate of 78 gallons / day, and the septic / settling tank was 1500 gallons. The bacteria mixture of nitrifiers and denitrifiers was fed at a rate of 11 ml / hr for 1 hour, each 6 hours, 4 times / day. The carbon / nutrient was added at a rate of 110 ml / hr, for 1 hr every 4 hours, for a total of 660 ml / day. Samples were taken after 14 days under the leaching field at a depth of 1 ft, and 2 ft and tested for nitrate nitrogen. The results are given in Table 1.

TABLE 1FIG. 2 Field Testing of Waste WaterNitratenitrogen, ppmBefore treatment1ft2ftunder the leaching field29-37ppm29-37ppmWith treatment as in FIG. 21ft2ftunder the leaching field10ppm2ppm

[0120] Ammonia was measured using a Hanna Instruments Inc, 584 Park East Drive, Woonsocket, R.I. 0289...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com