Wiring board and production method thereof, and semiconductor apparatus

a technology of wiring board and production method, applied in the direction of plasma technique, printed circuit aspects, metal adhesion improvement of insulation substrates, etc., can solve the problem of requiring tens of microns of an uneven spot to ensure sufficient adhesion, and difficult to create fine wiring with a line width not exceeding tens of microns, etc. problem, to achieve the effect of easy mounting multiples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

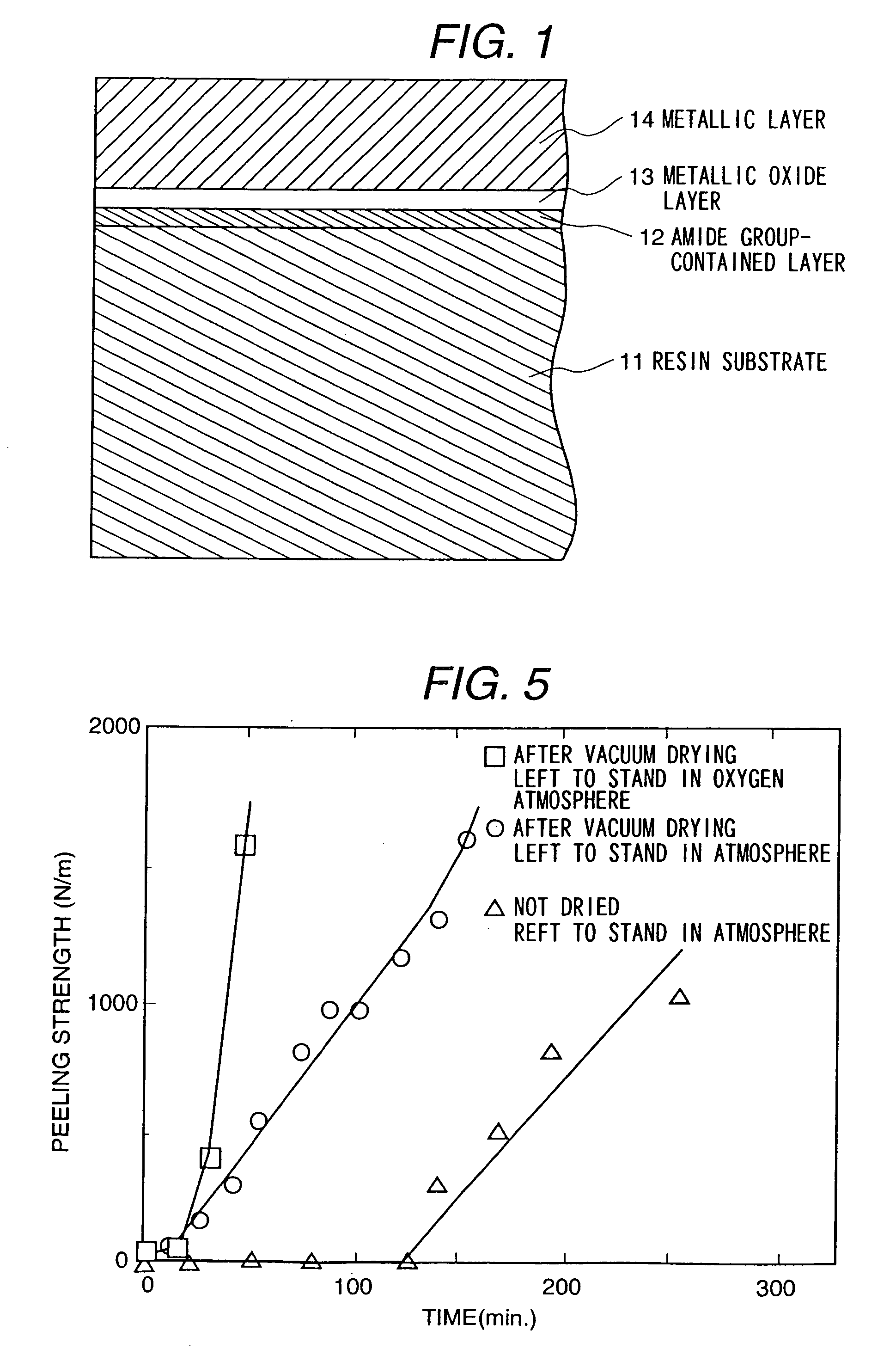

embodiment 1

[0071] Polyimide film resin substrate, Kapton 200H by Dupont having a surface roughness of 0.1 am or less was used. A 10 cm×10 cm sample was created, and was treated in aqueous solution for surface modification at a liquid temperature of 25° C. for 2 minutes.

[Composition of aqueous solution for surface modification]Sodium hydroxide100 g / lEthylene diamine 70 g / lEthanol100 g / l

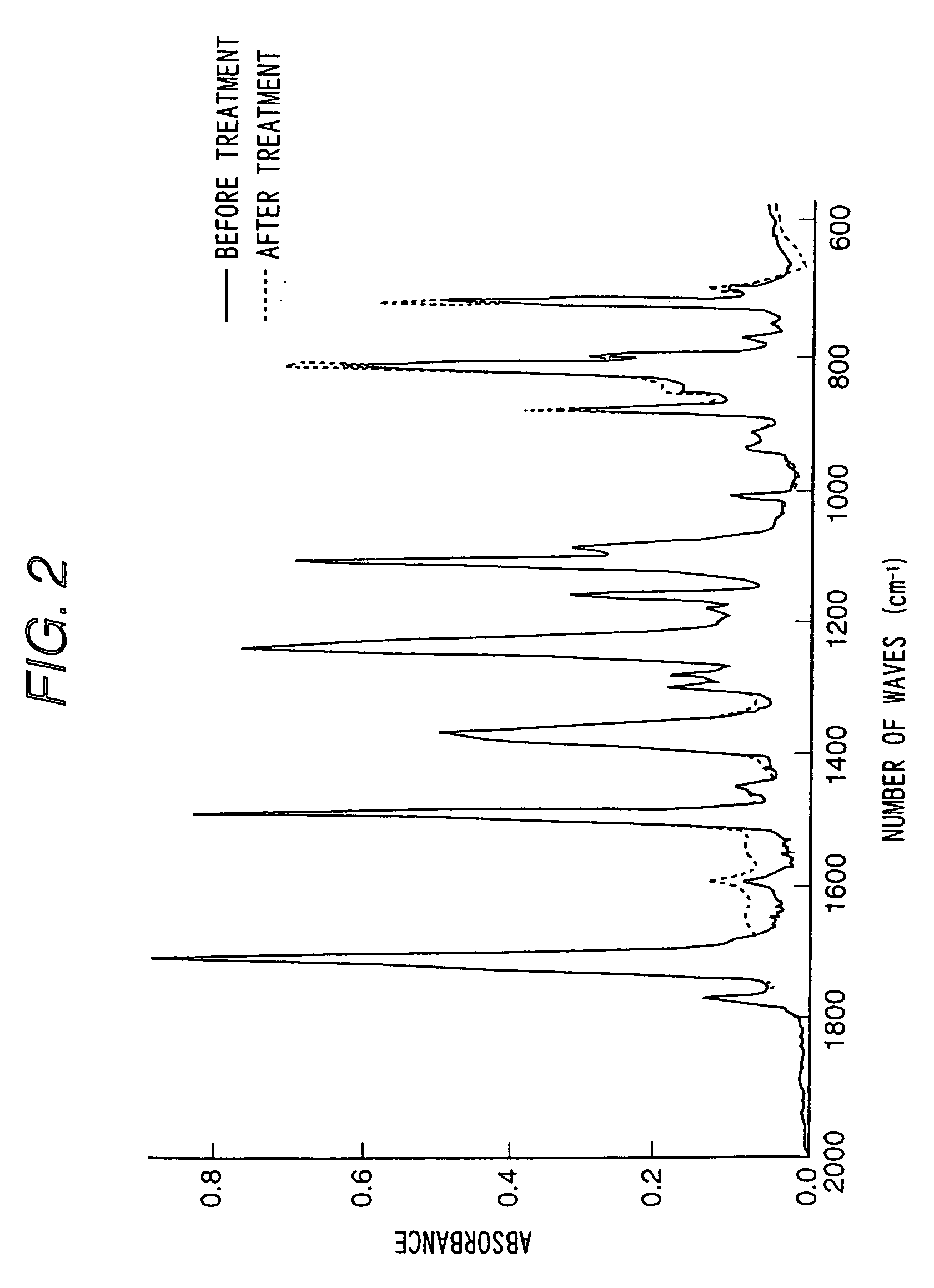

[0072] A treated sample was bonded on the epoxy resin substrate with glass cloth, and was vacuum dried at 25° C. for 3 hours. Then the sample surface was pressed against the germanium prism to measure total reflection infrared absorption. Then absorption peak specific to amide group was observed in the vicinity of 1650 cm−1 and 1550 cm−1, in addition to absorption peak in the vicinity of 1780 cm−1 and 1720 cm−1 which were attributable to the carbonyl group of the imide ring. This shows that amide group is introduced on the surface by this surface treatment. This sample was subjected to plating catalyst treatmen...

embodiment 2

[0074] Kapton 200H by Dupont was used as Polyimide film. A 10 cm×10 cm sample was created, and was treated in aqueous solution for surface modification (the same one used in the First Embodiment) at a liquid temperature of 25° C. for 2 minutes. After treatment, the sample was bonded on a glass epoxy resin substrate, and was subjected to plating catalyst treatment according to the specified method using the circuit breakers 3040, 3340 and 4041 by Japan Mining. Then electroless nickel plating solution (B-1 by Okuno Seiyaku) was used to deposit nickel to a film thickness of about 0.1 μm. After plating, the sample was separated from glass epoxy resin substrate, and was left to stand in the flow of oxygen for one hour after having been vacuum dried for three hours while kept heated to a temperature of 40° C. X-ray was irradiated from the polyimide film side at a low angle to measure diffraction spectrum and to check the interface between the polyimide film and nickel film, thereby verify...

embodiment 3

[0075] Kapton 200H by Dupont was used as Polyimide film. Four 5 cm×5 cm samples were created, and was treated in aqueous solution for surface modification (the same one used in the First Embodiment) at a liquid temperature of 25° C. for 2 minutes.

[0076] After treatment, the sample was bonded on a glass epoxy resin substrate, and was vacuum dried 25° C. for three hours. Then cobalt, tin, copper and nickel were deposited on the sample by sputtering to a thickness of about 1 μm. After that, the sample was separated from glass epoxy resin substrate, and was left to stand in the flow of oxygen for one hour. X-ray was irradiated from the polyimide film side at a low angle to measure diffraction spectrum and to check the interface between the polyimide film and metallic film, thereby verifying presence of oxides at the interface for any metal samples. Copper was then deposited on each sputtered metal film by copper electroplating to a film thickness of about 20 μm under the same condition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| velocity | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com