Composition for forming anti-reflective coating for use in lithography

a technology of anti-reflective coating and composition, which is applied in the direction of photosensitive materials, instruments, photomechanical equipment, etc., can solve the problems of random reflection and standing wave off the substrate, and achieve the effects of effective reflection prevention, useful anti-reflective coating, and high reflection prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

synthesis example 1

Synthesis of Resin

[0064] After 90 g of 2-hydroxypropyl methacrylate was dissolved in 455 g of propylene glycol monomethyl ether, the reaction solution was warmed at 70° C. and simultaneously nitrogen gas was passed into the reaction solution. Thereafter, 0.9 g of azobisisobutyronitrile (manufactured by JUNSEI CHEMICAL CO., LTD.) was added as polymerization initiator and stirred under nitrogen atmosphere for 24 hours, and then 0.1 g of 4-methoxyphenol (manufactured by TOKYO KASEI KOGYO CO., LTD.) was added as polymerization terminator. The resulting resin was subjected to GPC analysis and as a result, its weight average molecular weight was found to be 71,300 in terms of standard polystyrene. The solids content in the solution was 20%.

synthesis example 2

[0065] Cresol novolak resin (manufactured by ASAHI CIBA CO., LTD., trade name ECN1299, weight average molecular weight: 3,900, the structure being shown by formula (5)) was provided.

[0066] 10 g of cresol novolak resin described above was added in 80 g of propylene glycol monomethyl ether and dissolved therein. To the solution, 9.7 g of 9-anthracenecarboxylic acid and 0.26 g of benzyltriethylammonium chloride were added. The resulting mixture was reacted at 105° C. for 24 hours. GPC analysis of the resulting polymer resin gave a weight average molecular weight of 5,600 in terms of standard polystyrene. The chemical structure of the resin is shown by formula (6).

synthesis example 3

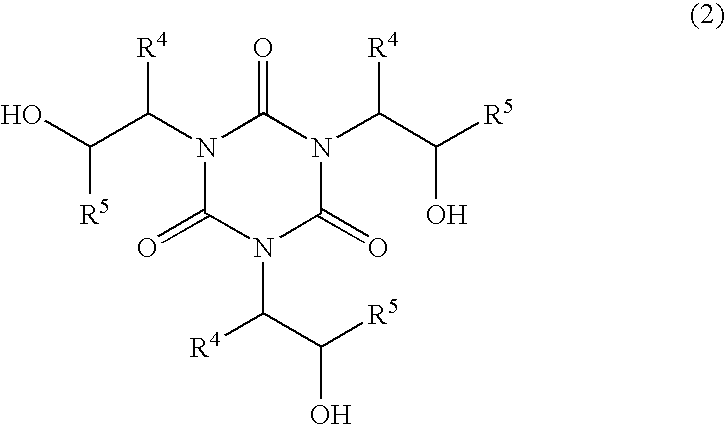

[0067] Tris-(2,3-epoxypropyl)-isocyanurate (manufactured by NISSAN CHEMICAL INDUSTRIES, LTD., trade name TEPIC, the structure being shown by formula (7)) was provided.

[0068] 3.0 g of the above-mentioned tris-(2,3-epoxypropyl)-isocyanurate was added and dissolved in 7.0 g of xylene. Then 2.8 g of phenol and 0.17 g of benzyl triethyl ammonium chloride were added to the dissolved solution, and thereafter reacted at 140° C. for 24 hours. After the reaction was completed, the reaction solution was gradually cooled, crystals separated out were filtered, and then purified by recrystalization from a mixed solvent of isopropylalcohol / acetone=9 / 1. The chemical structure of the resulting compound is shown by formula (8).

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com