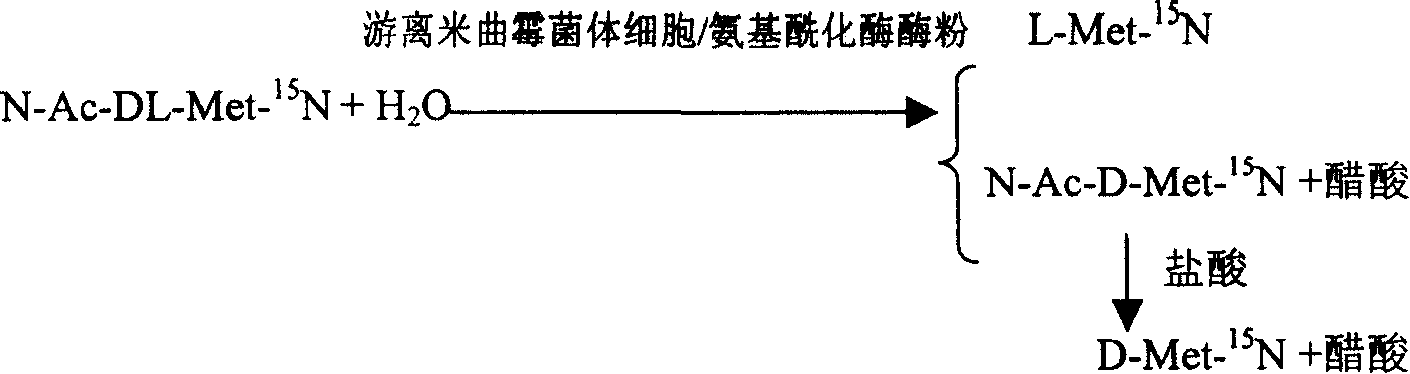

Enzyme method for detaching and preparing L-methionine-15N and D-methionine-15N

A technology for enzymatic separation and methionine, which is applied in the field of separation of racemic compounds, can solve the problems of intermittent operation and small production scale, and achieves the effects of no decrease in abundance, solution of decomposition in the presence of oxygen, and high optical purity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take a storage slant, pick 5 rings of slant spores with an inoculation loop, put it into a triangular flask filled with 100ml sterile water, shake it well, and further dilute it to 10 -4 ~10 -8 times. Draw 0.2ml each into a 9cm-diameter plate filled with Zapei's medium, put it into a 30°C incubator and cultivate it for 3 days. After growing green spores, select a single colony and transfer it to the slant of Chapei's medium, and culture it in a 30°C incubator for 4 days. After growing green spores, add 3ml of sterile water to each tube, stir gently with a glass rod, and draw 0.5ml of the spore suspension was inserted into a 500ml Erlenmeyer flask filled with 50ml of soybean juice medium, and cultured at 30°C with shaking at 200rpm for 50h. After lowering the shaker, filter with suction, wash with distilled water, and collect aspergillus oryzae thallus pellets with a diameter of 2.0 to 3.0 mm for future use.

Embodiment 2

[0025] Weigh 5g of acetyl-DL-methionine solid, dissolve it with dilute NaoH, then adjust the volume to 500ml, then adjust the pH to about 7.0 with dilute hydrochloric acid, weigh 25g of wet free Aspergillus oryzae cells or 0.5g of aminoacyl Mix the enzyme powder into the prepared substrate, put the Erlenmeyer flask containing the substrate and enzyme in a water shaker at 37°C, 120 rpm and keep it warm for 48 hours to stop the reaction. At this time, the hydrolysis rate is close to 100%. . Evaporate the reaction solution to 1 / 5 of the original volume with a rotary evaporator at 45°C, adjust the pH to about 2 with 2mol / L hydrochloric acid, and flow through a 1500H strong Ion exchange columns for acidic cation exchange resins. Begin to collect effluent N-acetyl-D-methionine- 15 N, wash the upper column with distilled water for 3 times, and then wash the column with distilled water until the effluent is colorless, pH neutral, and free of N-acetyl-D-methionine- 15 When N flows o...

Embodiment 3

[0027] Combine the water eluting liquid that goes up column for the first time among the embodiment 2, at 45 ℃ Concentrate it to obtain N-acetyl-D-methionine- 15 N concentrate, which is at 90 ℃ Under nitrogen protection, hydrolysis with 4mol / L hydrochloric acid, N-acetyl-D-methionine- 15 The mass volume ratio of N to hydrochloric acid is 1:10, and the reflux reaction time is 5 hours. After the hydrolysis reaction is completed, under the protection of nitrogen, after the temperature drops to room temperature, adjust the pH to about 2 with 10mol / L NaoH, and flow through 300ml of 1500H type strongly acidic cation exchange with a flow rate of 0.04ml / min.g carrier at a constant speed. Resin ion exchange column, washed with water to remove impurities such as sodium chloride, until the effluent is colorless and Cl-free - Afterwards, use 0.2mol / L ammonia water to elute, and collect a single spot at 45 ℃ Concentrate under low temperature, catch ammonia, decolorize with activated ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com