Composite microorganism beta-dextranase and beta-glucosaccharase production method

A technology of glucosidase and compound microorganism, which is applied in the field of production of compound microorganism β-glucanase and β-glucosidase, which can solve the restriction of the application of β-glucanase and the inability to cellobiose and cellotriose Degradation, affecting the hydrolysis efficiency of β-glucan, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Trichoderma viride and Aspergillus niger are mixed and fermented to produce composite microbial β-glucanase and β-glucosidase, made by composite microbial β-glucanase and β-glucosidase Solid enzyme preparation and liquid enzyme preparation, the physical and chemical properties of solid enzyme preparation are:

[0053] (1) Enzyme activity: β-glucanase activity 16000mg glucose / g h, β-glucosidase activity 3300μg glucose / g min,

[0054] (2) Particle size: the preparation can pass through No. 3 standard sieve,

[0055] (3) Moisture: the water content is less than 8%,

[0056] (4) Sensory indicators: yellow powder, uniform color,

[0057] (5) Hygienic indicators: the total number of bacteria per gram of solid enzyme preparation is less than 10,000;

[0058] The physical and chemical properties of liquid enzyme preparations are:

[0059] (1) Product enzyme activity: β-glucanase activity 4500mg glucose / g h, β-glucosidase activity 860μg glucose / g min,

[0060] (2) Sensory i...

Embodiment 2

[0063] Trichoderma viride bacterial classification and Aspergillus niger bacterial classification are made into inclined-plane bacterial classification respectively and preserve;

[0064] Trichoderma viride adopts Chapek`s agar medium (1L) (Czapek`s agar, CZ), and the medium is:

[0065] Sucrose 30g, sodium nitrate 2.0g, dipotassium hydrogen phosphate 1.0g, magnesium sulfate heptahydrate 0.5g, potassium chloride 10.5g, ferrous sulfate 0.01g, agar 15g, pH 7.2-7.4;

[0066] Aspergillus niger adopts potato culture medium (1L) (Potato dextrose agar, PDA), and culture medium is:

[0067] 200g potatoes, 20g glucose, 3g dipotassium hydrogen phosphate, 1.5g magnesium sulfate heptahydrate, 12g agar, natural pH;

[0068] Slant strain culture of Trichoderma viride and Aspergillus niger: use the corresponding culture medium for Trichoderma viride and Aspergillus niger respectively, inoculum size 5-10%, culture statically at 28-30°C for 20-48 hours, put in 4°C refrigerator save as figur...

Embodiment 3

[0070] Inoculate the slant strains of Trichoderma viride and Aspergillus niger respectively in 500ml Erlenmeyer shaker flasks, shake culture on the shaker, mix the medium ratio materials of Trichoderma viride and Aspergillus niger, and mix the culture medium in proportion The materials are divided into conical shake flasks, each bottle is 100 ml, placed in an autoclave, set the temperature at 121 ° C, sterilized for 30 minutes, and after natural cooling, the medium proportioning materials in the conical shake flasks are respectively Inoculate Trichoderma viride strains and Aspergillus niger strains, and carry out shaking flask culture;

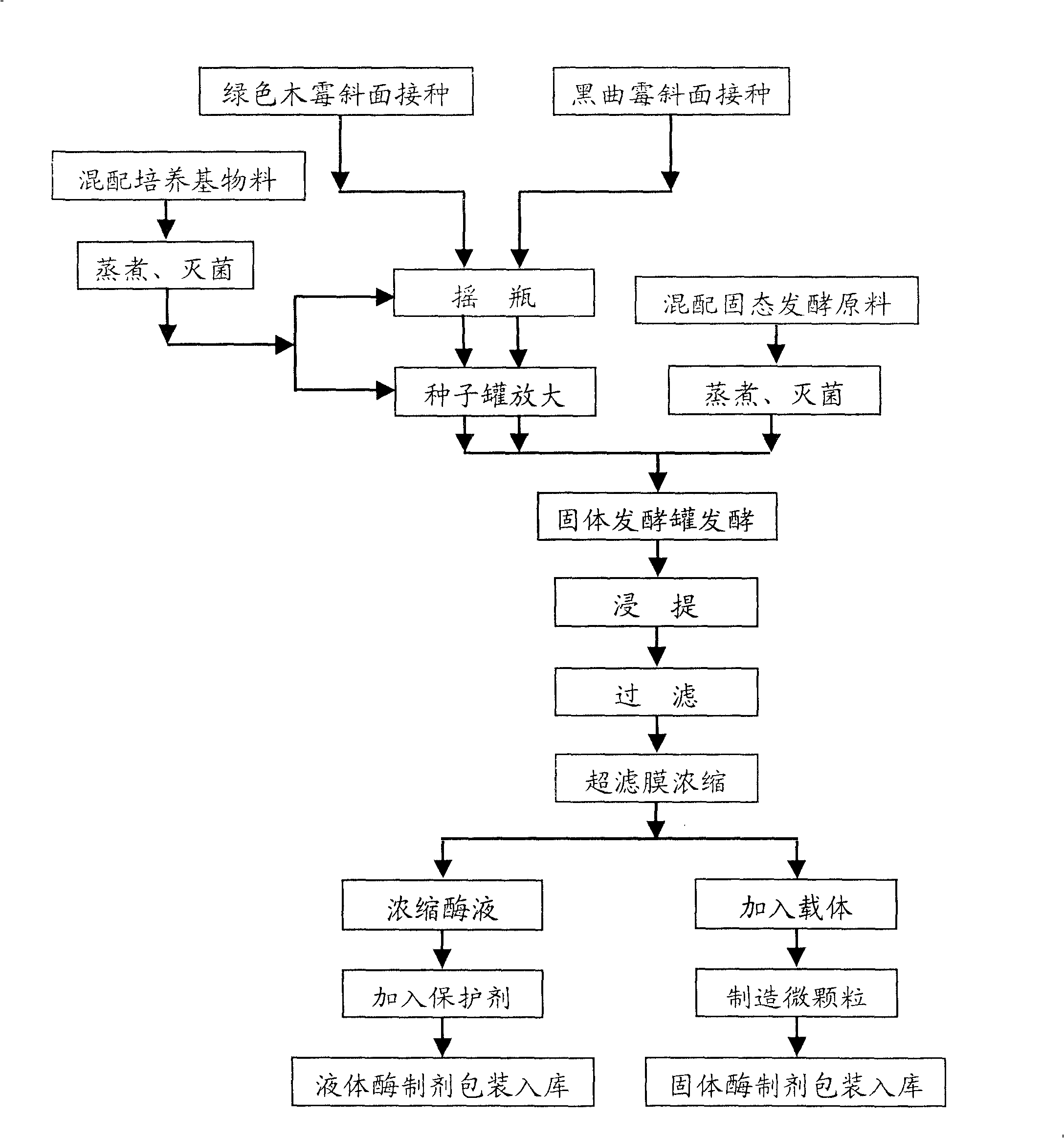

[0071] Shake flask culture conditions: temperature 28-30°C, rotation speed 180-250 rpm, inoculum size 1-3%, culture for 48-60h, such as figure 1 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com