Positive electrode material Li(1+X)V3O8 of Li-ion battery preparing process

A technology for lithium ion batteries and positive electrode materials, which is applied in the field of preparation of layered compound Li1+xV3O8 lithium ion battery positive electrode materials, can solve the problems of expensive materials, fast capacity decay, difficulty and the like, and achieves low preparation cost and reduced reaction time. , Powder uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

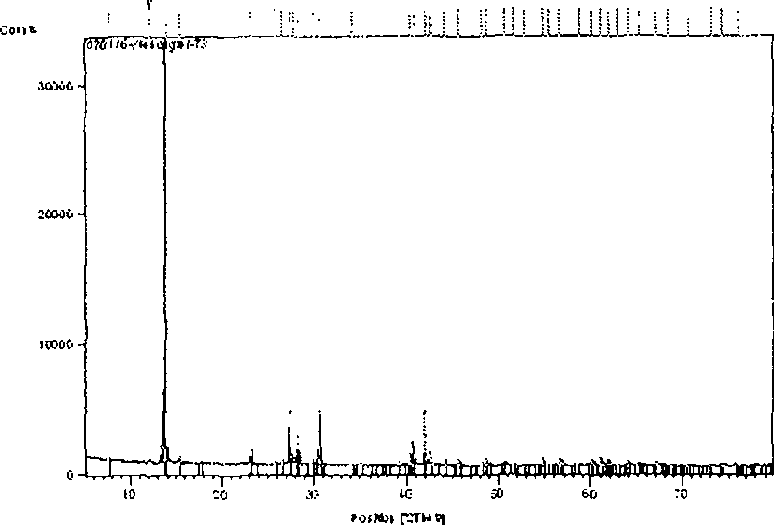

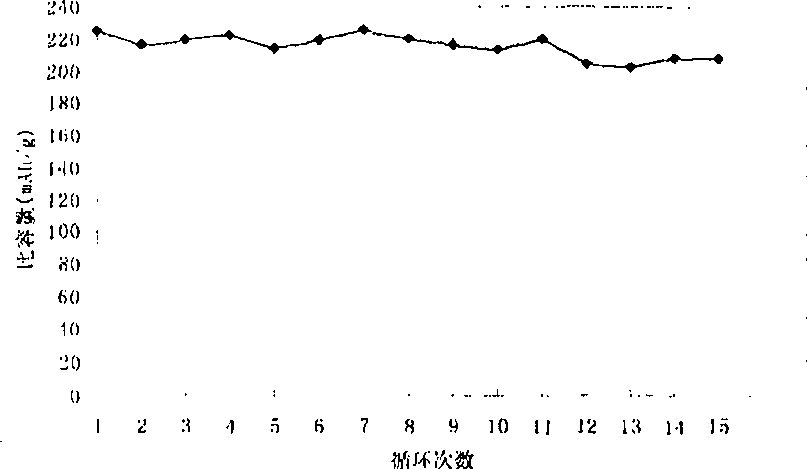

[0028] Embodiment 1: Lithium citrate, ammonium metavanadate, EDTA and citric acid are weighed with the molar ratio of 1:2.25:3:1; Lithium citrate, ammonium metavanadate, EDTA are put into reaction kettle earlier, Add lithium carbonate, ammonium metavanadate and EDTA substance amount total amount 20 times of distilled water to it again, be heated to 50 ℃ and magnetic stirring, dissolve, and solution first becomes orange red, finally becomes deep blue transparent solution; Will weigh The citric acid taken was prepared to a concentration of 2.5mol L -1 Slowly add the aqueous solution of citric acid dropwise into the dark blue transparent solution under stirring. The process is accompanied by the release of air bubbles. After the citric acid is added dropwise, continue to stir for 1h, evaporate the water at 80°C, and then vacuum the solution at 10°C. 4 Pa, vacuum-dry at 110°C for 4 hours to obtain a blue-gray solid precursor, put it in a mortar, grind it evenly, put it in a roaste...

Embodiment 2

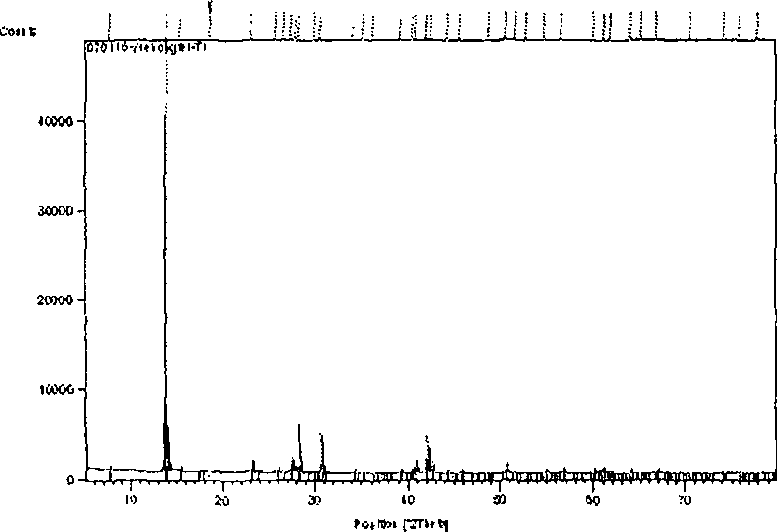

[0029] Embodiment 2: Lithium citrate, ammonium metavanadate and EDTA are taken by weighing with the mol ratio of 1:3:3, put into reactor, then add lithium carbonate, ammonium metavanadate and EDTA material amount total wherein Measure 20 times of distilled water, heat to 60°C and magnetically stir to dissolve, the solution first turns orange, and finally turns into a dark blue transparent solution, then continue to stir for 1 hour, evaporate the water at 70°C, and then vacuum at 10 2 Pa, vacuum-dry at 120°C for 4 hours to obtain a blue-gray solid precursor, put it in a mortar, grind it evenly, put it in a roasting furnace, sinter and synthesize it at 630°C for 20 hours, cool with the furnace, grind and sieve Get Li 1+x V3 o 8 The positive electrode material, the X-ray diffraction result of the material is as follows image 3 . Adopt present embodiment to synthesize Li 1+x V 3 o 8 The material is the positive electrode active material, acetylene black is the conductive ag...

Embodiment 3

[0030] Embodiment 3: Lithium citrate, ammonium metavanadate and citric acid are weighed in the ratio of 1:3.75:4 with molar ratio; Lithium carbonate and ammonium metavanadate are put into reaction kettle first, add carbonic acid to wherein Distilled water with 10 times the total amount of lithium and ammonium metavanadate is heated to 70°C under a magnetic stirrer and stirred to make it a uniform light yellow suspension; the citric acid is prepared with water to a concentration of 5.0mol· L -1 The solution was slowly dripped into the solution in the reaction kettle under stirring, the color of the solution first turned orange red, and finally dark blue, accompanied by the release of air bubbles; evaporated to dryness at 85°C, and then for 10 3 Pa, vacuum drying at 130°C for 4 hours to obtain a fluffy and porous blue-black solid precursor; then put the black solid precursor in a mortar and grind it evenly, put it in a roasting furnace, and sinter and synthesize it at 600°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com