Candida lipolytica and the erythritol producing process therewith

A technology of Candida lipolytica and erythritol, which is applied in the field of microbial fermentation, can solve the problems of unfavorable product purity and high cost of erythritol, and achieves improved extraction yield, reduced production cost, and reduced pollution and harmful wild impurities. The effect of bacterial risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

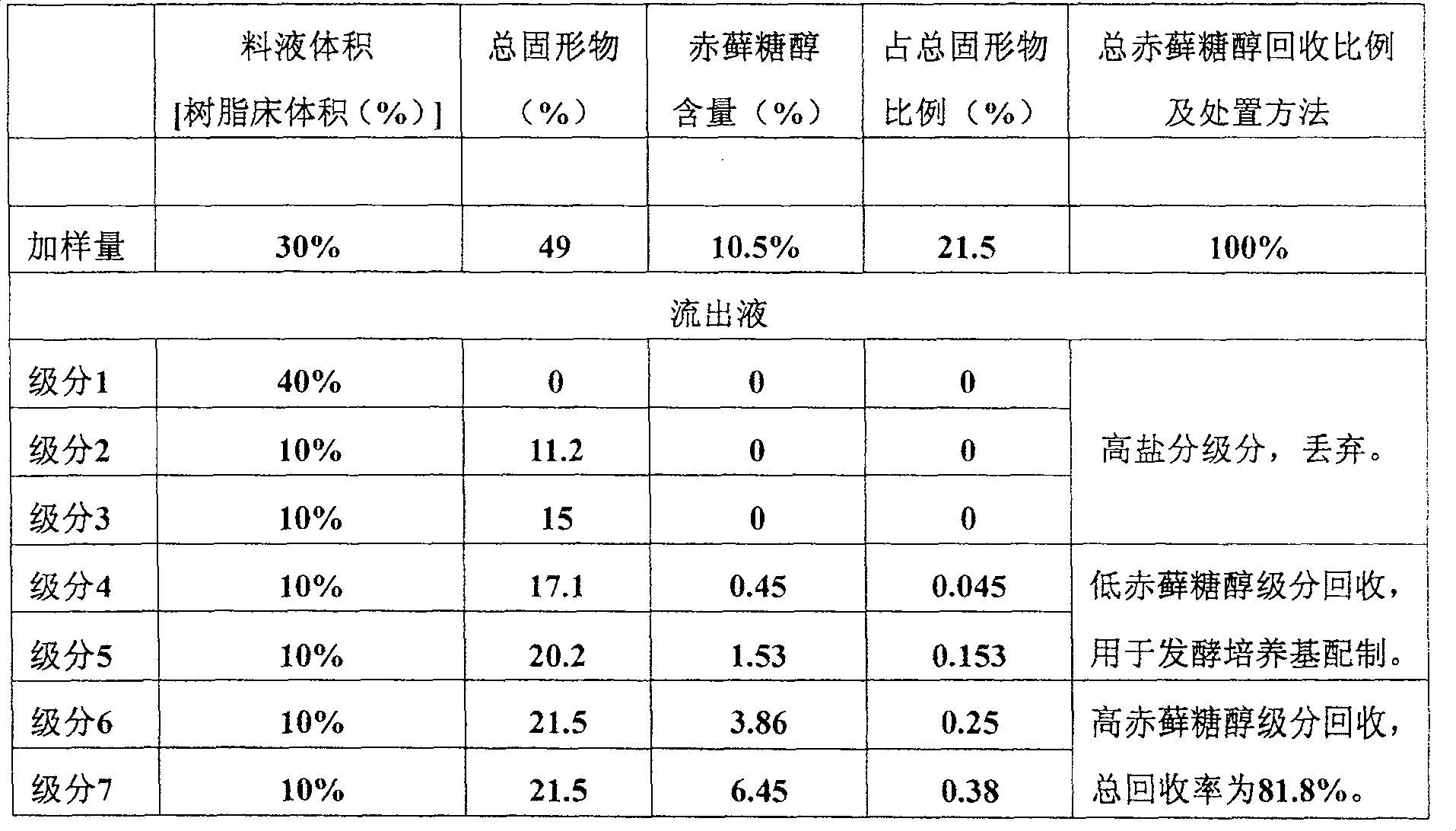

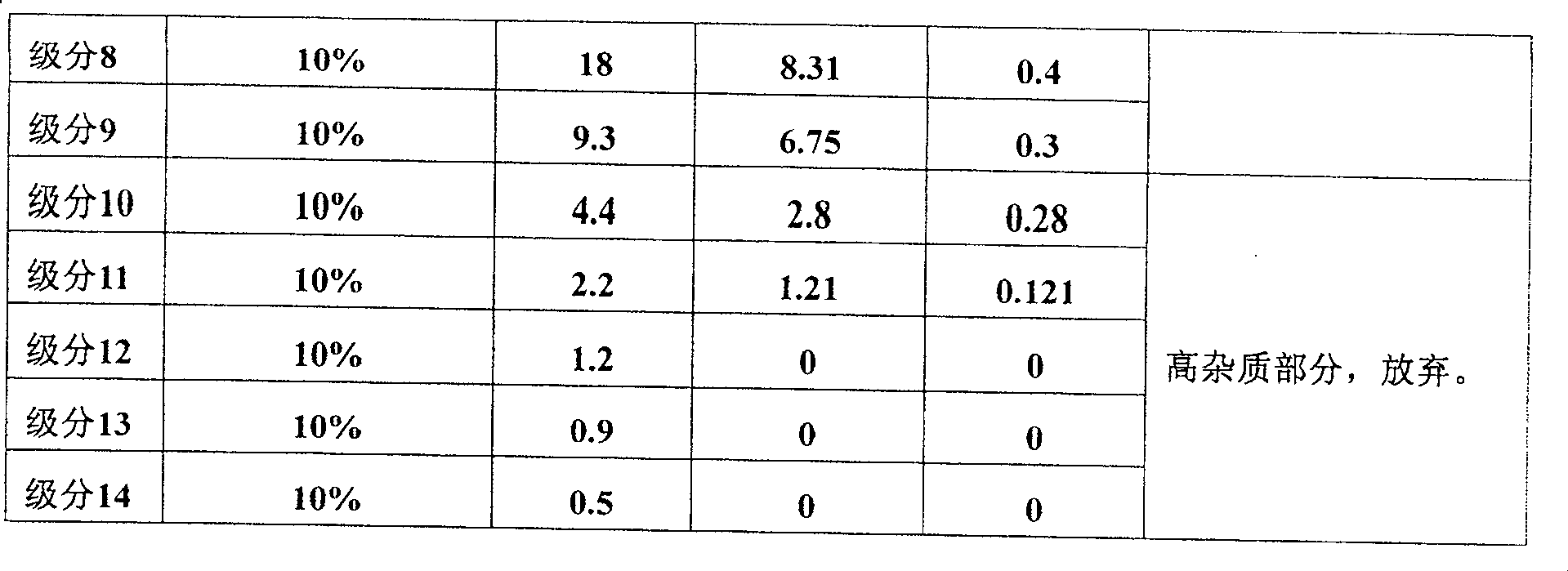

[0050] In a 5-ton fermenter, 3.5 tons of feed liquid containing culture medium are put into the medium, and the proportion of the culture medium is as follows: 900 kilograms of glucose, 21 kilograms of yeast extract, 3 kilograms of potassium dihydrogen phosphate, 1.5 kilograms of magnesium sulfate, and 20 kilograms of ammonium sulfate . The inoculum amount is 10%, the stirring speed is 200r.p.m, and the air volume is 30m 3 / h, dissolved oxygen 20%, tank pressure 0.5atm, temperature 30°C-31°C, fermentation time 132 hours, wherein, after 24 hours, the pH of the fermentation broth was controlled between 2.6-2.9, red Bacterol 15.4%, residual sugar less than 0.5%, sugar alcohol conversion rate 47%. Membrane filtration is performed on the fermented liquid, the solid bacteria residue is filtered off, the filtrate is decolorized with activated carbon, desalted through an ion exchange column, and the feed liquid is concentrated at 65°C under reduced pressure until the content of eryth...

Embodiment 2

[0052] In this example, relatively cheap corn steep liquor was used instead of yeast extract, and the components of the medium were simplified to reduce the cost of the fermentation medium. In a 5-ton fermenter, 3.5 tons of feed liquid containing a culture medium were dropped into, and the proportion of the culture medium was as follows: 1120 kilograms of glucose, 157.5 kilograms of corn steep liquor, and 35 grams of copper chloride. The inoculum amount is 10%, the stirring speed is 200r.p.m, and the air volume is 30m 3 / h, dissolved oxygen 20%, tank pressure 0.5 atm, temperature 30 ℃ ~ 31 ℃, fermentation time 130 hours, erythritol in the obtained fermentation broth is 15.3%, residual sugar is less than 0.5%, sugar alcohol conversion rate is 45.4 %. Membrane filtration is performed on the fermented liquid, the solid bacteria residue is filtered off, the filtrate is decolorized with activated carbon, desalted through an ion exchange column, and the feed liquid is concentrated ...

Embodiment 3

[0054] In this example, the recovered yeast is used to autolyze instead of commercial yeast extract, which can significantly reduce the cost of the medium, and at the same time reduce the discharge of waste water containing solid impurities, thereby improving the environment. Take fresh yeast slime (with a water content of 80%), adjust the pH to 6.5-7.5 with 1mol / l sodium hydroxide solution, incubate at 45-55°C for 24-48 hours, and recover the filtrate after filtration. In a 5-ton fermenter, 3.5 tons of feed liquid containing a culture medium are put into the feed, and the ratio of the culture medium is as follows: 1120 kilograms of glucose, 500 kilograms of yeast autolysate with a solid content of 7%, 1.05 kilograms of potassium dihydrogen phosphate, sulfuric acid Magnesium 0.7 kg, ammonia 3.5 kg, copper chloride 35 grams. Inoculation after sterilization, inoculum size 10%, stirring speed 200r.p.m, air volume 30m3 / h, dissolved oxygen 20%, tank pressure 0.5atm, temperature 30℃...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com