Calcium phosphate composite bone cement containing eucommia leaf extractive and preparing method thereof

An extract and Eucommia leaf technology, applied in the intersection of material science and biomedicine, can solve the problems of reducing the compressive strength of CPC, slowing down the degradation speed of CPC, prolonging the solidification time of CPC, etc., to promote bone formation and clear the extraction method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

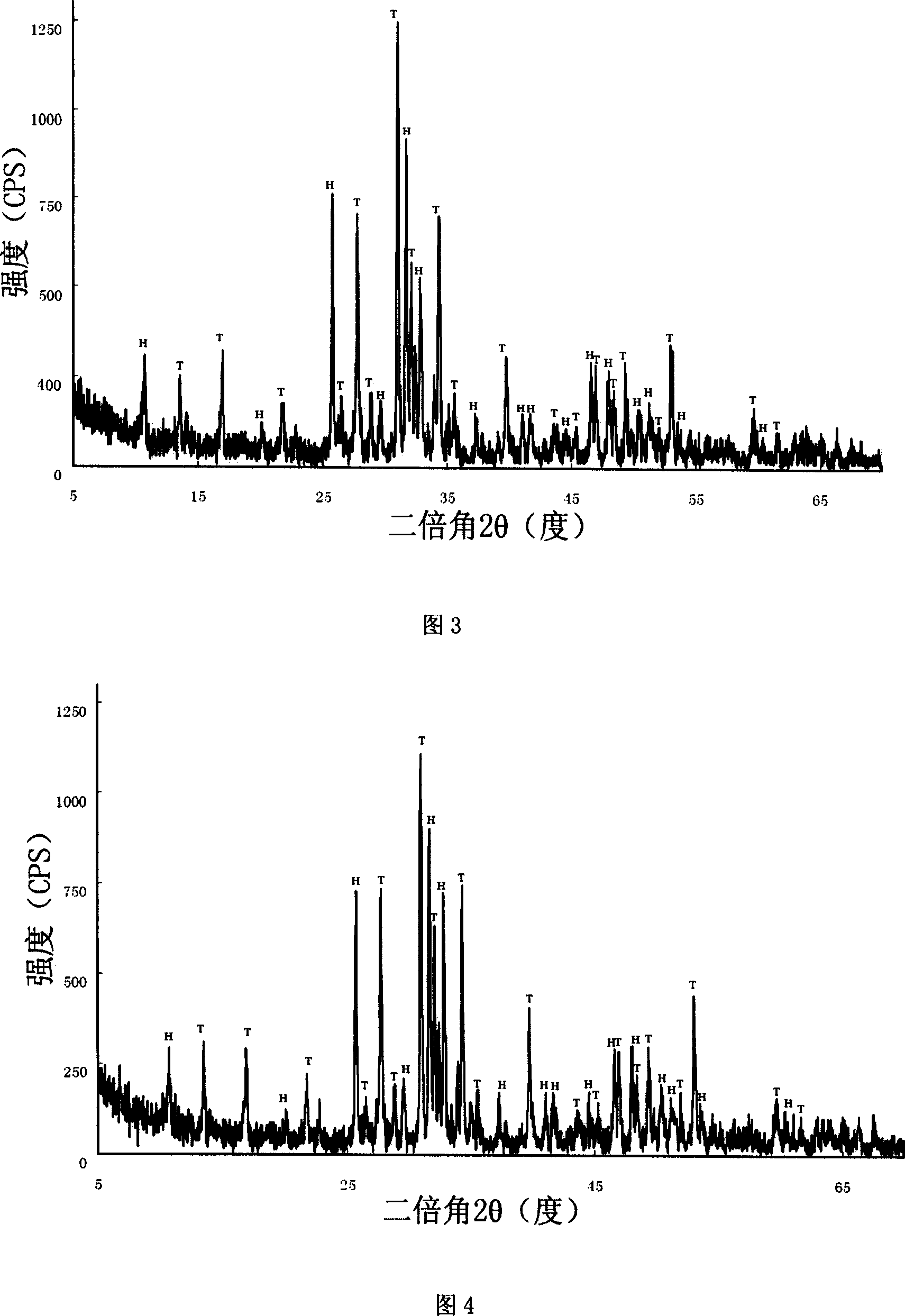

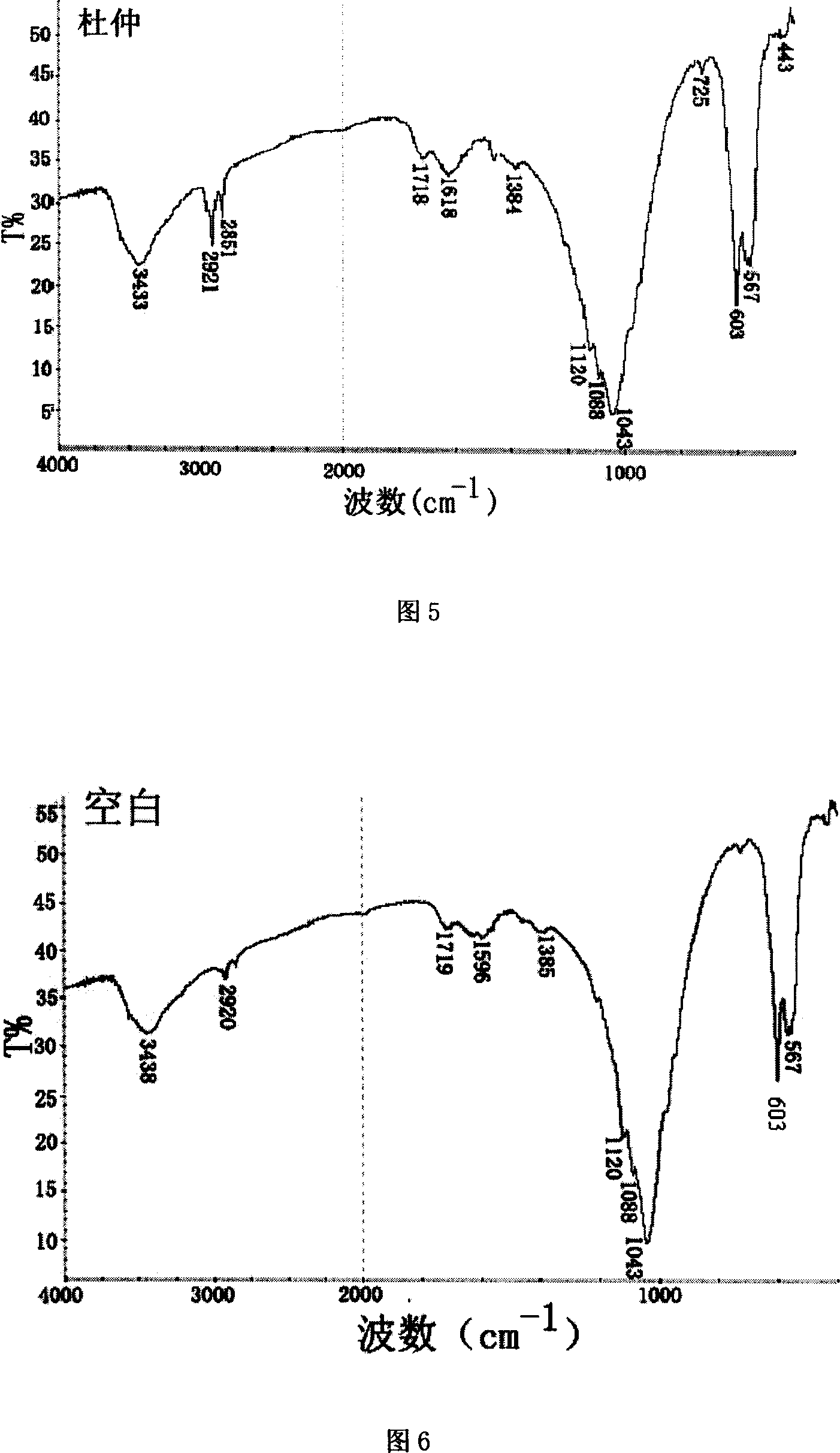

[0029] Example 1 Preparation method of calcium phosphate composite bone cement loaded with Eucommia leaf extract

[0030] (1) Preparation of the solid phase part: crush the fresh bovine reticulated bone into 1cm 3 size, rinsed repeatedly with double distilled water, immersed in 30% H at 38°C 2 O 2After being in the solution for 72 hours (changing the solution every 24 hours), wash with double distilled water for 30 minutes, soak in absolute ethanol for 24 hours, wash again with double distilled water for 30 minutes, and soak in acetone for 24 hours to make partially deproteinized and defatted bone grains. Finally, wash with double distilled water for 30 minutes and then dry at 70°C for 3 days. Then calcined at 800°C in a muffle furnace (heating at a speed of 10°C / min) and kept for 6 hours. The calcined bone particles were immersed in 0.3M diammonium hydrogen phosphate (AP) solution, soaked at 70°C for 24 hours, absorbed excess AP solution on the surface with filter paper, a...

Embodiment 2

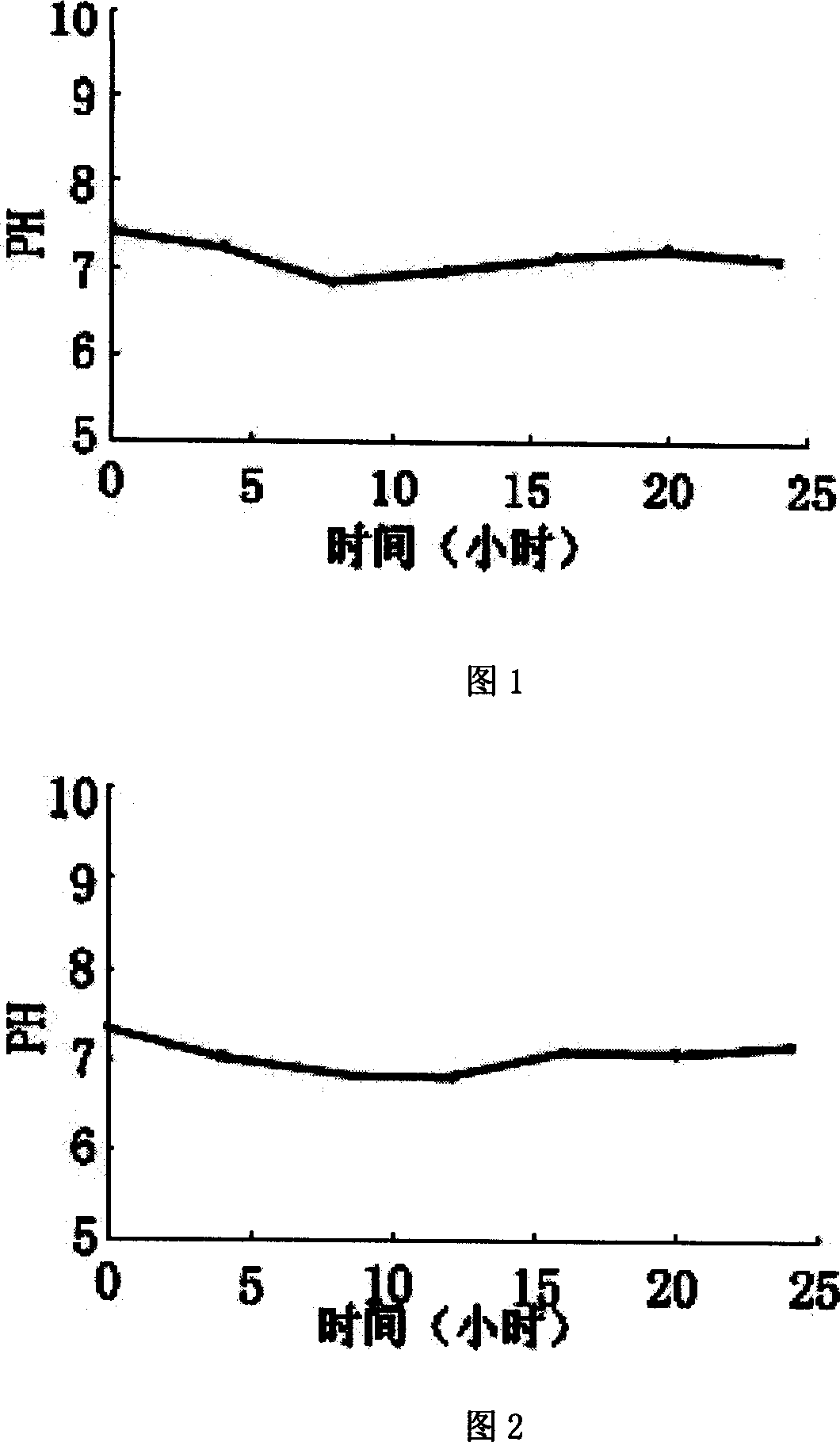

[0035] Determination of curing time of calcium phosphate composite bone cement loaded with Eucommia leaf extract

[0036] Add a certain amount of eucommia leaf extract to the solidified liquid (ie, the liquid phase) in advance, so that the final concentrations of the eucommia leaf extract in the solidified liquid are 0, 0.152, 0.304, and 0.608 mg / ml respectively. Weigh 1g of the solid phase part, then add the liquid phase part according to the liquid / solid ratio of 0.35ml / g, fully mix evenly with a stainless steel mixing knife on a clean and dry glass plate, and control the ambient temperature at about 23±1°C. The blending time is 60-90 seconds. When the blend is in the form of a paste, fill it into a template with a diameter of 10mm and a height of 2mm, and fill the blend to the level. From the first minute after the end of the reconciliation, put the template into an incubator at 37°C and a relative humidity greater than 90%, and place a needle poke meter with an indenter di...

Embodiment 3

[0040] Determination of Compressive Strength of Calcium Phosphate Composite Bone Cement Containing Eucommia Leaf Extract

[0041] A certain amount of Eucommia leaf extract was added to the solidified solution in advance, so that the final concentrations of the Eucommia leaf extract in the solidified solution were 0 and 0.608 mg / ml respectively. According to the liquid / solid ratio of 0.35ml / g, add the solidification liquid to the solid phase part, fill the mixture into stainless steel molds with an inner diameter of 4mm and a height of 6mm within 60 seconds, compact it firmly, and screw on the compression screw. Put it in a constant temperature box with a relative humidity greater than 30% at 37°C, remove the mold after 1 hour, and immediately immerse the sample in simulated body fluid (SBF) at 37°C, keep the constant temperature for 23 hours, take it out, smooth both ends of the sample, and accurately measure each The diameter and height of a test piece. The compressive stren...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com