Method of extracting saponin from turmeric after separating starch and fiber

A process method and separation technology, applied in the field of phytochemical process engineering, can solve the problems of high production cost, low yield of saponin, large water consumption, etc., to ensure yield and quality, reduce production cost, and reduce waste water discharge volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

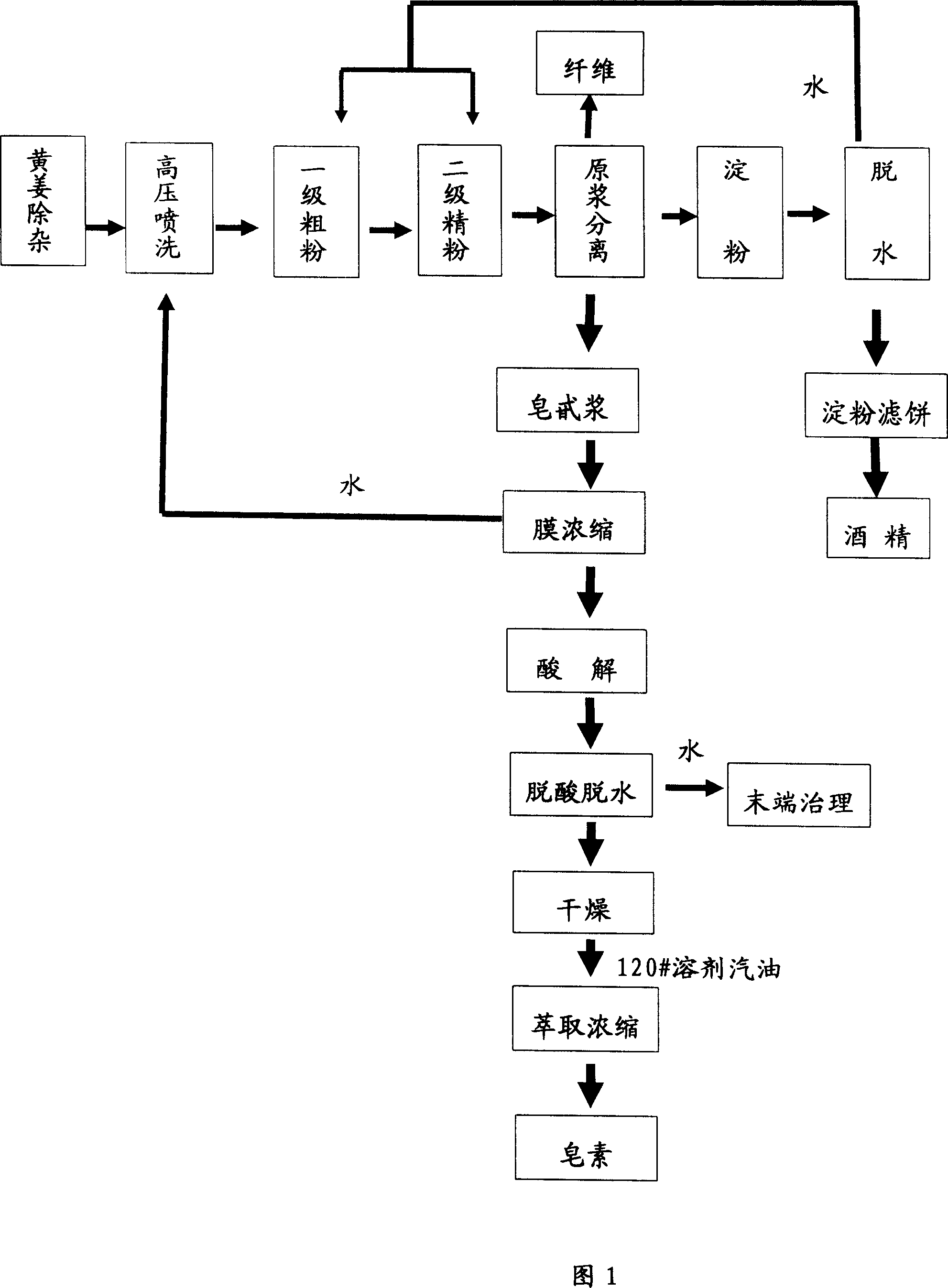

[0022] According to the process flow diagram shown in Fig. 1: describe in detail that the specific embodiment of the present invention is as follows:

[0023] (1) Primary treatment of raw materials: Use a multi-functional impurity remover to remove silt, stones, hairs and other sundries in the turmeric, then enter the squirrel-cage ginger washing machine for high-pressure spray washing, and then carry out first-level coarse powder, second-level Fine powder, so that the particle size of the turmeric slurry reaches 30-80 mesh, and the concentration is between 14-18%;

[0024] (2) Separation of starch and fiber: adopt 14-17 groups of starch countercurrent scrubbers to separate 90% of starch and 80% of fiber from the stock solution, and simultaneously obtain the saponin pulp mixture;

[0025] (3) Precipitation and dehydration: heat the saponin mixture at 32-40°C, put it in the sedimentation tank for natural precipitation for 6-8 hours, extract the supernatant and concentrate it wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com