Fire-resistant non-injury fracturing fluid thickening agent and preparation method and usage thereof

A fracturing fluid thickener and high-temperature resistance technology, which is applied in the directions of chemical instruments and methods, drilling compositions, etc., to achieve the effects of improved temperature resistance, safety, easy industrial production, and improved high temperature resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

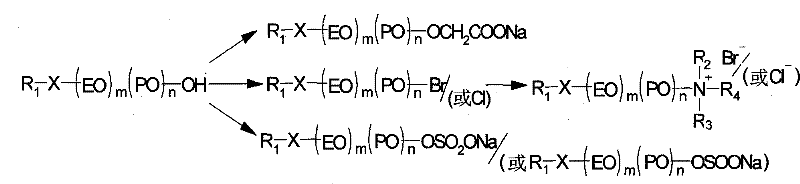

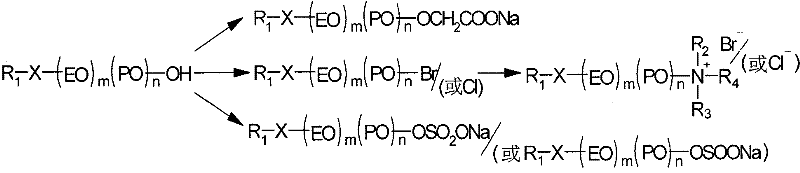

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Preparation of cationic thickener polyethylene oxide monobehenate methyl dihydroxyethyl ammonium bromide (DHAB-2)

[0021] Weigh 2040g (6 moles) of behenic acid and 17g of tetramethylammonium chloride, put them into a 5-liter autoclave, heat up to 125°C, and mix them with ethylene oxide under a pressure of 0.45MPa 721 g (16.4 mol) were reacted and matured for 5 hours. Then open the pressure relief valve at 75°C and vent slowly. It is washed with 2Kg of 10% salt water, dehydrated and filtered to obtain 2510 g of polyethylene oxide monobehenate.

[0022] According to the standard GB 7385-1987 method to analyze the content of ethoxy group, the average added mole number of ethylene oxide is 2.2. The fatty acid reacted with ethylene oxide in this step can also be replaced by fatty alcohol or fatty amine with equivalent carbon chain length. In addition to quaternary onium salts, Lewis acids or Lewis bases can also be used as catalysts in this reaction.

[0023] Weigh ...

Embodiment 2

[0028] Example 2: Preparation of anionic thickener polyethylene oxide monobehenate sodium sulfate (DSN-2)

[0029] Weigh 100g (0.25 mol) of polyethylene oxide monobehenate prepared in Example 1, put it in a 250mL three-necked flask, heat it to 115~120℃, and keep stirring for 10~15 minutes Add 25.5g (0.37mol) of sulfamic acid, stir and react at 120-125°C for 2 hours, cool to room temperature, add sodium hydroxide to neutralize, until the pH value reaches 7.5-8.5. The crude product was recrystallized with a mixed solvent of acetone and ethyl acetate at a volume ratio of 75:25, and then dried at 60°C to obtain 89 g of pure yellowish powder, which was measured according to the standard GB / T 5173-1995 method The content of anionic surfactant was 96.3%, and the yield was 77.4%.

Embodiment 3

[0030] Example 3: Using cationic thickener DHAB-2 to prepare high temperature non-damaging fracturing fluid

[0031] Take three beakers with a capacity of 500 ml, add 200 ml of a 2% (weight fraction) potassium chloride aqueous solution to each beaker, and add 2g, 4g and 6g of the DHAB- synthesized in Example 1 into the three beakers. 2. Stir fully to dissolve completely, and get a harmless fracturing fluid;

[0032] The viscosity of the fracturing fluid at different temperatures was measured by Brookfield PVS rheometer. The results are shown in the following table:

[0033] Temperature(℃) 60 80 100 110 120 130 Viscosity (cp) 170S -1 1%DHAB-2 115 63 28 - - - 2%DHAB-2 162 124 106 74 22 - 3%DHAB-2 308 246 184 120 72 48

[0034] It can be seen from the above table that the temperature resistance of fracturing fluid increases with the increase in the amount of thickener DHAB-2; however, without adding any high temperature stabilizer, the fracturing fluid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com