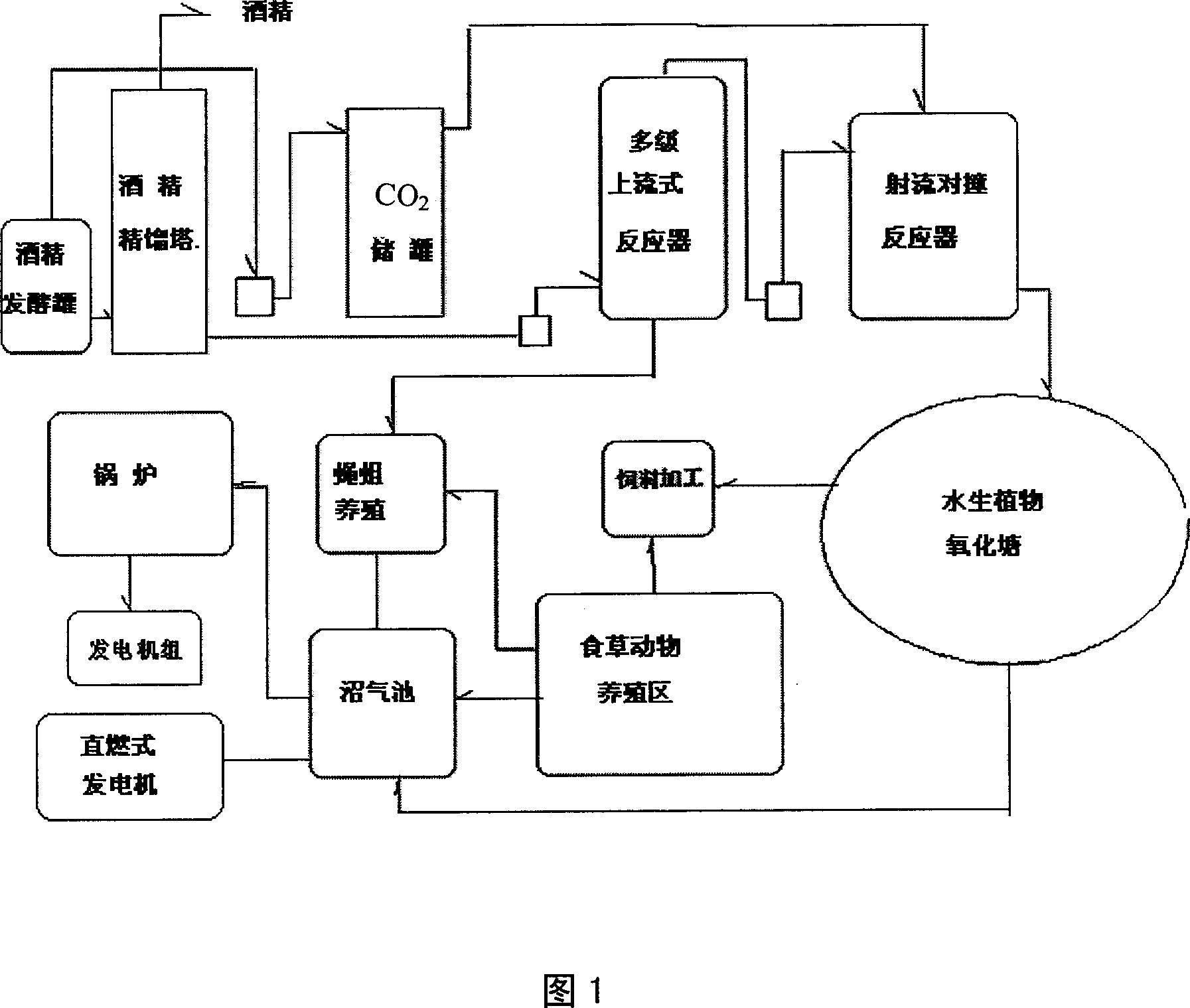

Method for multipurpose use of starch, spirit wastewater and equipment thereof

An alcohol waste water and alcohol waste liquid technology, which is applied to fertilizers, applications, and waste fuels made of biological waste, can solve the problems of complex operation and management, inability to achieve zero discharge, sensitivity to temperature changes, etc. The effect of land reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

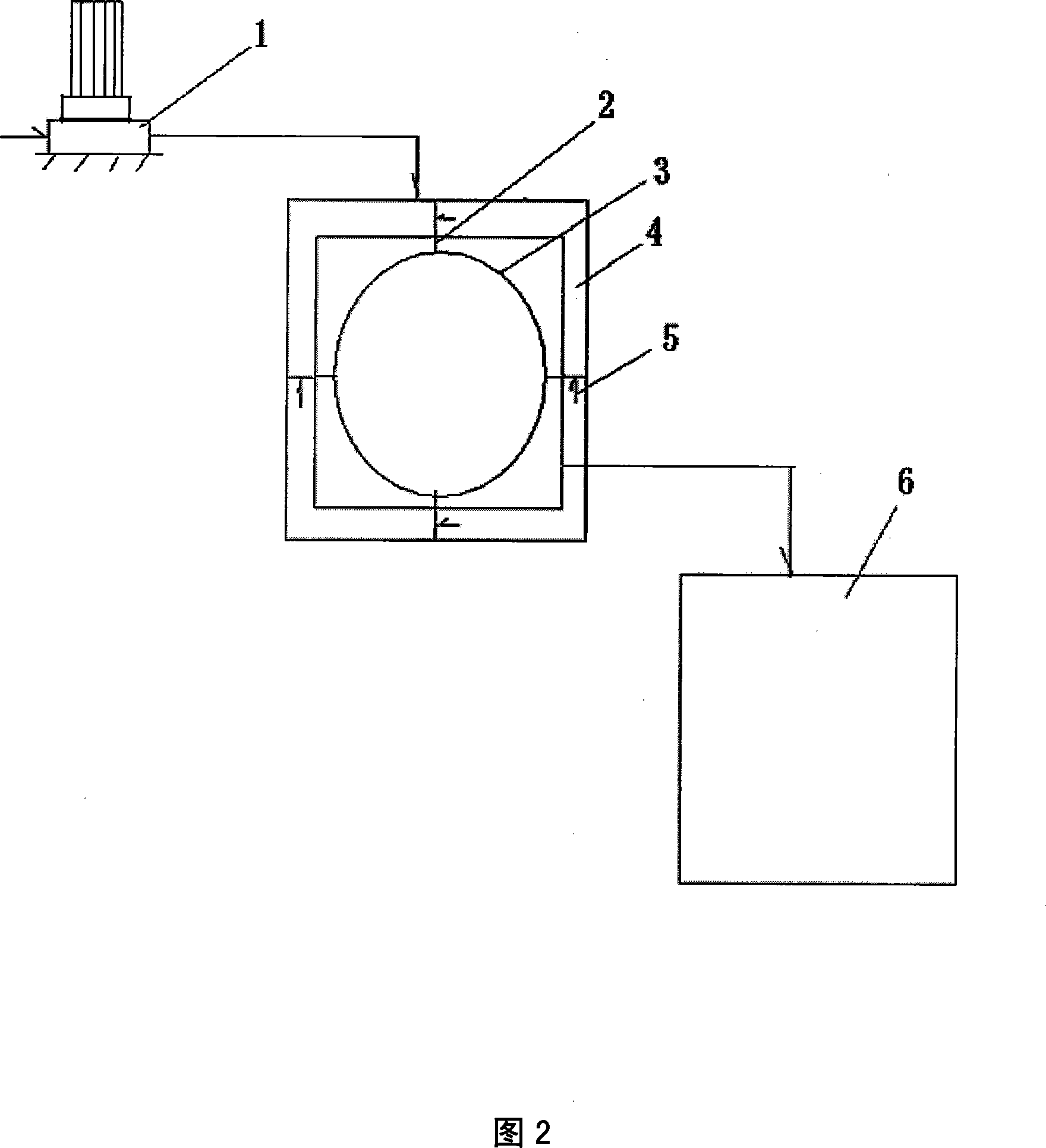

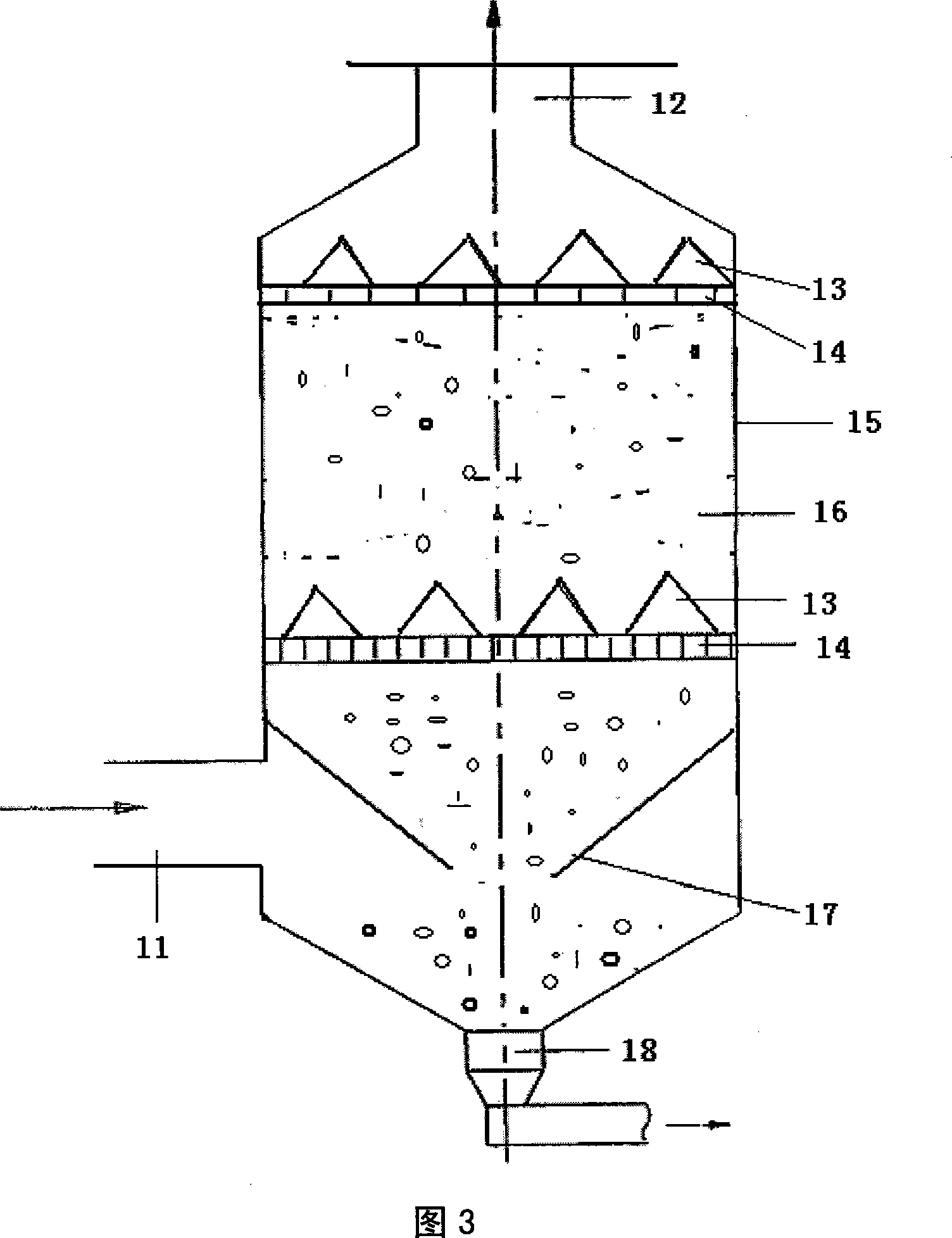

Method used

Image

Examples

Embodiment 1

[0033]In 2005, an alcohol factory affiliated to a cane sugar factory in a certain place in Guangxi discharged 50,000 tons of alcohol waste liquid per year. In the past, half of it was concentrated and burned, and the other half was used as boiler ash water, and then discharged to the oxidation pond after precipitation. The treatment was not thorough, and the oxidation pond The outlets often smell bad and are required to be rectified by the environmental protection department. In 2006, using the method and equipment of the present invention, the carbon dioxide produced by the alcohol fermentation tank was collected and compressed, and then led to the colliding jet mixing device, and the fermentation liquid entered the alcohol Alcohol is distilled from the distillation tower, and the waste liquid enters the upflow reactor to interact with the anaerobic microorganisms in the reactor. The microorganisms used in the upflow reactor are obtained from the sludge of the alcohol waste liq...

Embodiment 2

[0035] Project overview: A 50,000-ton alcohol factory in a certain place in Guangxi. Construction conditions: annual production of 50,000 tons of alcohol or 60,000 tons of starch or equivalent scale, perennial production technology: multi-stage upstream anaerobic system, collision type Jet mixing device, 200-300 m2 oxidation pond, direct-fired and turbine-driven combined biogas power generation; construction scale: 15,000 KW installed power plant; 100,000 tons / year organic fertilizer, etc.; economic benefit calculation: (1) Power generation part 1) 1 million tons of waste liquid and 17.35 million m of biogas 3 ;2) Oxidation pond energy crop biogas: 200 tons / mu×375m 3 / ton × 300 mu = 21 million m 3 ;3) Breeding, other wastes and base by-products: 30,000 tons / year×350m 3 / ton = 10.5 million m 3 ; 4) methane amount=(1735+2100+1050)×70%=3420m3; 3.1-3.2kwh can be generated by 1 cubic meter of purified biogas; calculation: 3420×3.1=109.24 million kwh. 5) Installed capacity 109...

PUM

| Property | Measurement | Unit |

|---|---|---|

| oxygen consumption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com