Method of producing spinel structured lithium titanate

A technology of structural lithium titanate and spinel, which is applied in chemical instruments and methods, lithium compounds, titanium oxide/hydroxide, etc., can solve the problems of difficult industrial transformation, complicated process, and high cost of raw materials, and achieve cheap raw materials, The effect of easy to obtain raw materials and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

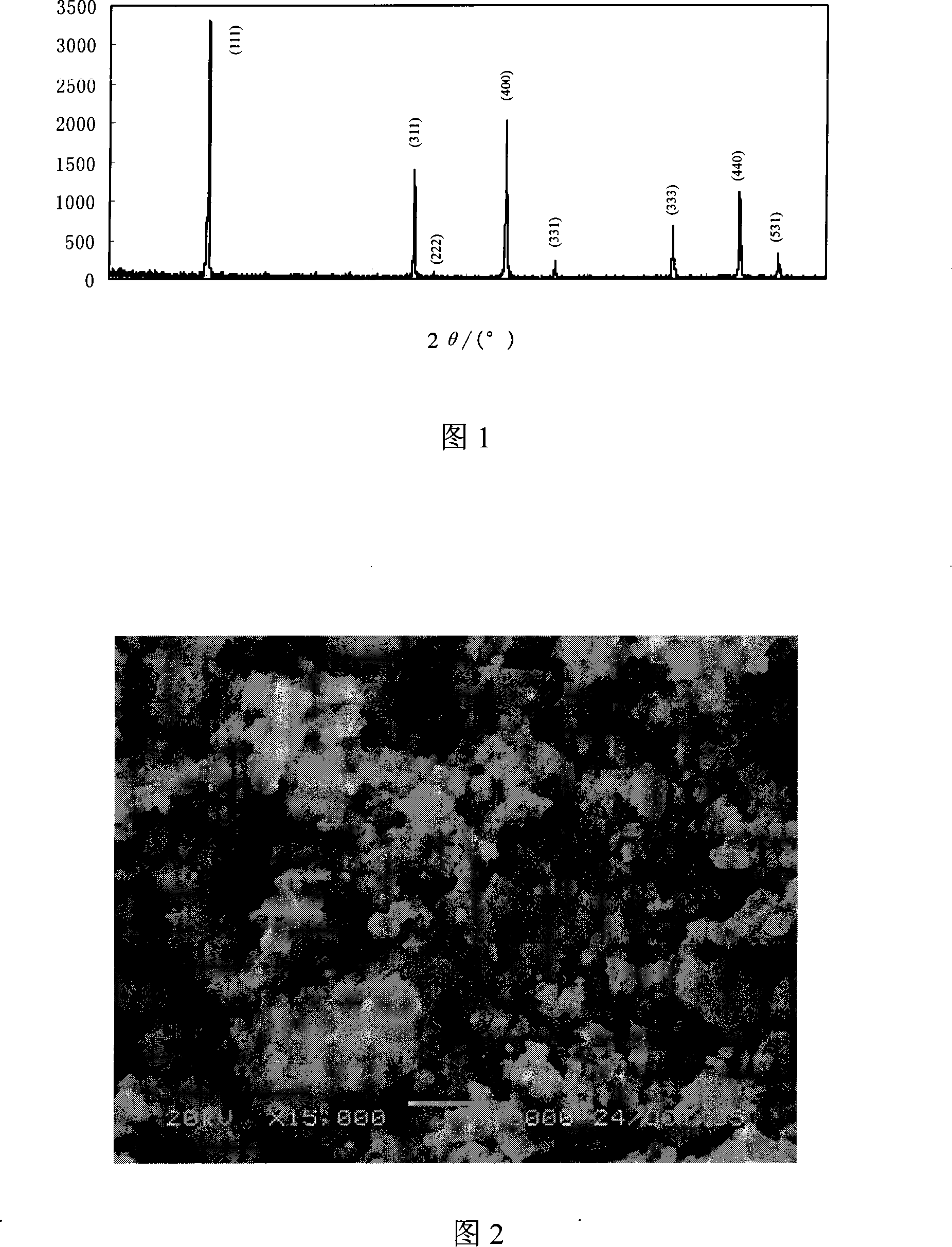

Embodiment 1

[0011] Commercially available analytically pure TiCl 4 (concentration is 99.9%) slowly add in ice-water bath 3mol / L hydrochloric acid solution and make TiCl 4 reserve solution. Separately take 5.0ml TiCl 4 Three parts of the stock solution were added to the TiO 2 ·nH 2 O precipitated completely. Filter with a medium-speed filter paper, wash until there is no chloride ion, dry the filter paper and the precipitate at 800°C for 4 hours, weigh after cooling, and determine the TiCl concentration in the standby solution accordingly. 4 The content is equivalent to 0.28g / ml titanium dioxide.

[0012] Take the above TiCl 4 15.3ml of stock solution, using the same steps as above to obtain TiO 2 ·nH 2 O, disperse with a small amount of water, add 12g citric acid, 1.700gLiOH·H 2 O, adjust pH ≈ 5 with commercially available analytically pure ammonia (concentration: 25% to 28%). Next, the mixture was stirred at about 80°C, and the TiO 2 ·nH 2 O gradually dissolves to form a solu...

Embodiment 2

[0018] Disperse 7.0g of titanium dioxide industrial intermediate metatitanic acid (moisture content 30%) in deionized water, add 10g of commercially available analytical pure reagent oxalic acid, 1.5g of commercially available analytical pure reagent lithium carbonate successively, and the rest of the operating steps are the same as in Example 1 same. Prepared Li 4 Ti 5 o 12 The average particle size of the powder is about 2.37 μm, and the XRD measurement results show that it has a spinel structure without other impurity phases. Charge and discharge at a constant current with a current rate of 0.5C. After 20 cycles, its specific capacity is greater than 122mAh / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com