Method for producing L-lactic acid and isoduicitol lactobacillus special for the same

A technology of Lactobacillus rhamnosus and lactic acid, applied in the field of L-lactic acid production, can solve the problems of high research difficulty and high production cost, and achieve the effects of improving utilization efficiency, controlling production cost and simplifying raw material processing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

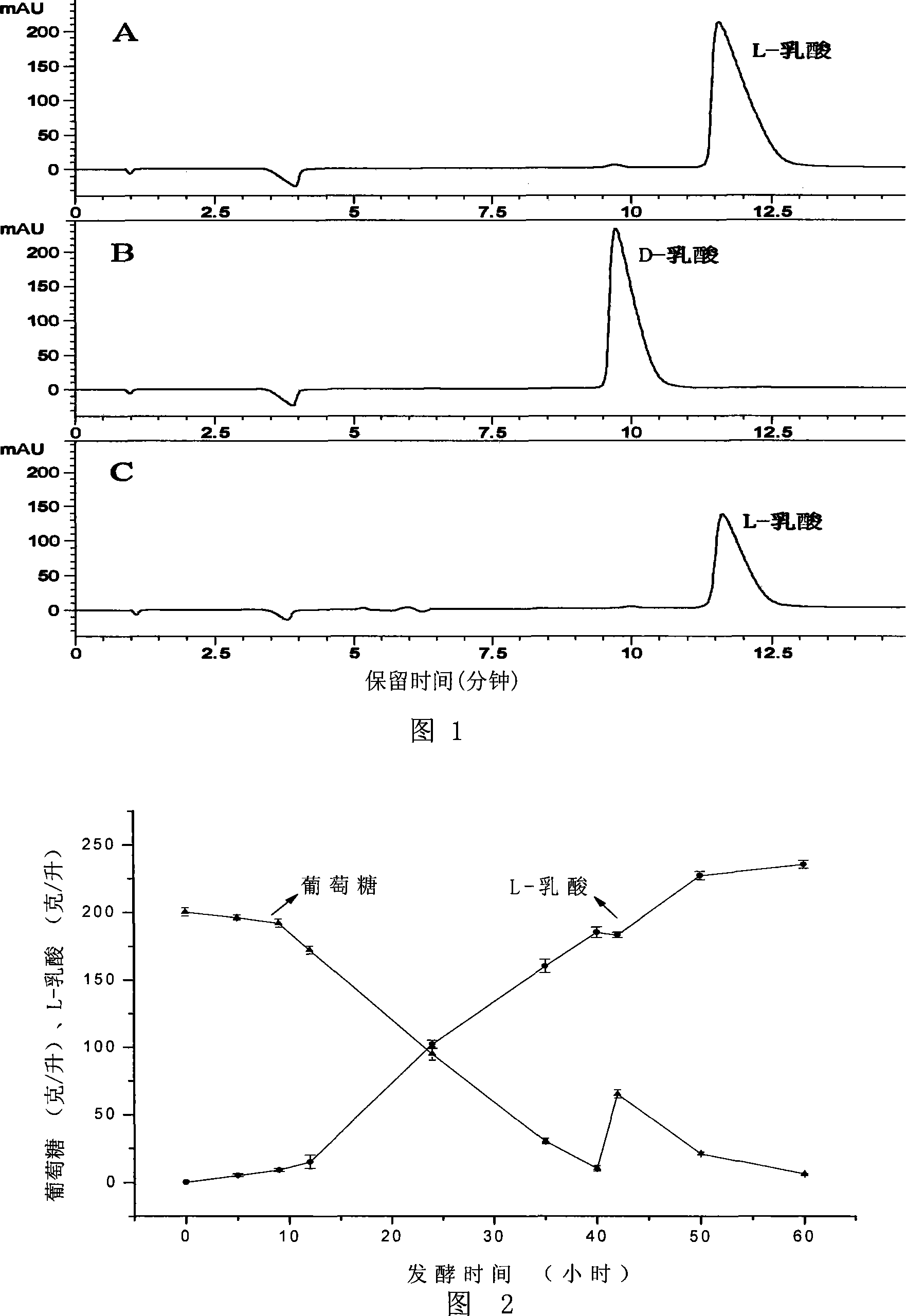

[0046] Example 1. Isolation, mutagenesis screening and identification of Lactobacillus rhamnosus (Lactobacillus rhamnosus) CASL CGMCC №2183

[0047] 1. Isolation and mutagenesis screening of strains

[0048] 1) Separation of strains

[0049] Obtain a soil sample near a milk factory in Jinan, Shandong, weigh 5 grams of soil sample into a 250ml Erlenmeyer flask, add 100ml of normal saline, mix well, dilute 10,000 times with sterile water and spread on MRS solid medium, 40℃ Cultivate, after the growth of single colonies, part of the single colonies will form a transparent circle due to acid production and the dissolution of calcium carbonate in the medium around the colonies. Pick a single colony with a large transparent circle, inoculate it in 10ml of fermentation medium, and culture it at 40°C for 72 hours, measure the concentration of L-lactic acid in the fermentation broth, pick a strain with the highest L-lactic acid production, and inoculate it in MRS Refrigerate on mediu...

Embodiment 2

[0067] Embodiment 2, utilize Lactobacillus rhamnosus (Lactobacillus rhamnosus) CASL CGMCC №2183 to produce L-lactic acid in Erlenmeyer flask fermentation method

[0068] The composition of the medium used in this embodiment is as follows:

[0069] Slant medium: glucose 20 g / L, yeast extract 5 g / L, peptone 10 g / L, beef extract 10 g / L, dipotassium hydrogen phosphate 2 g / L, diammonium citrate 2 g / L, acetic acid Sodium 5 g / L, Tween 80 1 mL / L, magnesium sulfate heptahydrate 0.58 g / L, manganese sulfate tetrahydrate 0.25 g / L, calcium carbonate 15 g / L, agar powder 15 g / L. The initial pH of the medium was 6.5. Sterilization was performed at 115°C for 20 minutes.

[0070] Seed medium: glucose 20 g / L, yeast powder 5 g / L, peptone 5 g / L, calcium carbonate 10 g / L. The initial pH of the medium was 6.5. Sterilization was carried out at 115° C. for 20 minutes.

[0071] Fermentation medium: industrial glucose (Zibo Hongyu Industrial Sugar Co., Ltd.) 150 g / liter, soybean meal hydrolyzate (pre...

Embodiment 3

[0077] Embodiment 3, utilize Lactobacillus rhamnosus (Lactobacillus rhamnosus) CASL CGMCC №2183 to produce L-lactic acid in Erlenmeyer flask fermentation method

[0078] The composition of the medium used in this embodiment is as follows:

[0079] The slant medium and seed medium are the same as in Example 2.

[0080] Fermentation medium: industrial glucose (Zibo Hongyu Industrial Sugar Co., Ltd.) 150 grams per liter, soybean meal hydrolyzate (preparation method is the same as in Example 1) 300 grams per liter, calcium carbonate 75 grams per liter. The initial pH of the medium was 7. Sterilization was carried out at 115° C. for 20 minutes.

[0081] The method for producing L-lactic acid by fermentation method of the present invention comprises the following steps:

[0082] (1) inclined plane culture: with embodiment 2;

[0083] (2) seed culture: with embodiment 2;

[0084] (3) Fermentation culture: 15 ml of the seed culture solution of step (2) was inserted into a 300 ml E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com