POSS hybrid hole-transporting material and preparation method thereof

A hole transport material and hole transport technology, which are applied in the field of POSS hybrid hole transport materials and their preparation, can solve the problems of affecting the interface characteristics of organic light-emitting devices, affecting the overall performance of organic light-emitting devices, etc., and achieve good hole transport. performance, improve interface performance, and improve the effect of transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

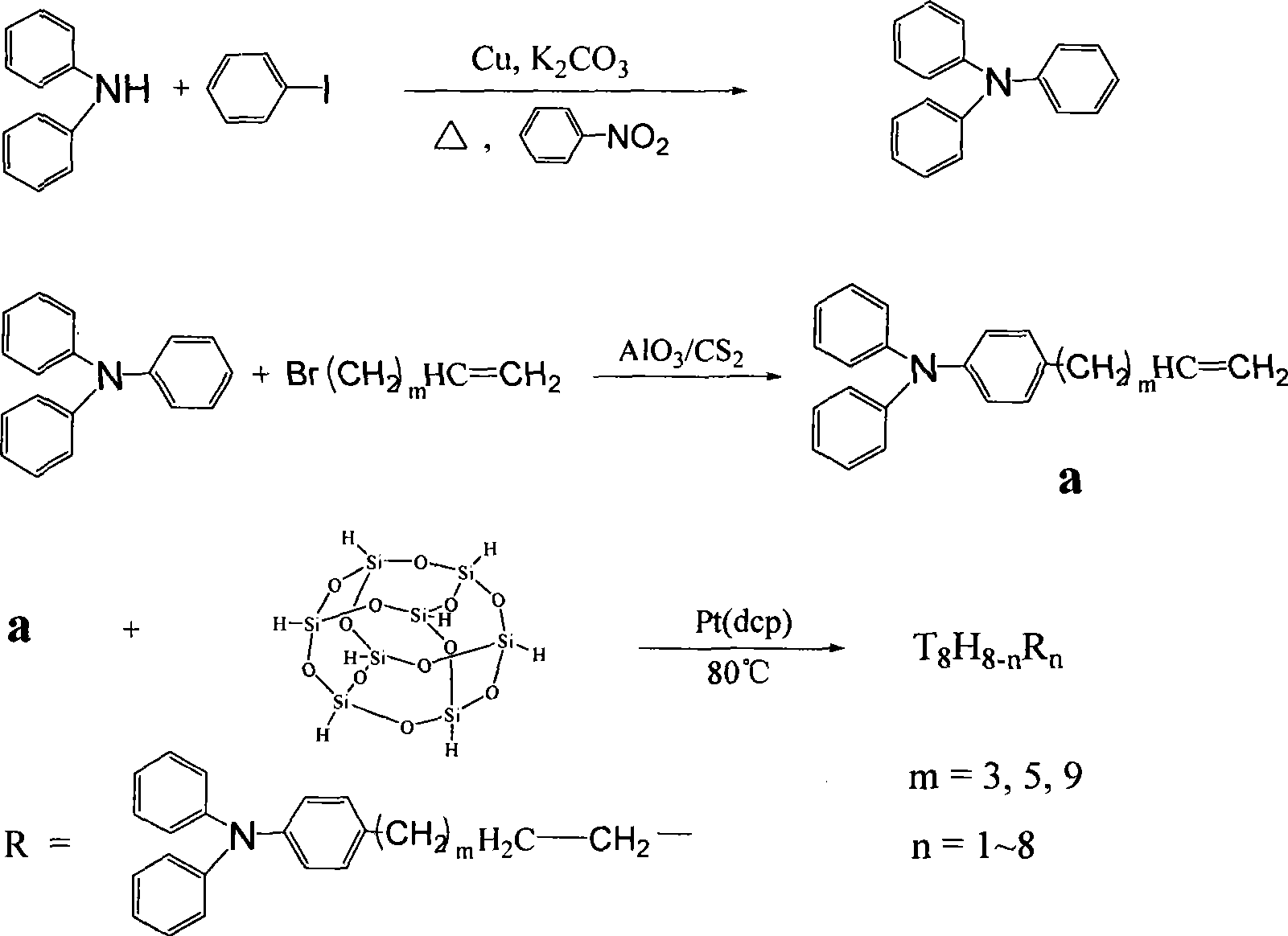

Embodiment 1

[0021]In a 100mL round-bottomed three-necked flask, add 1.76g of ground diphenylamine, 2.04g of iodobenzene, 0.11g of nitrobenzene, 1.38g of finely powdered anhydrous potassium carbonate and 0.05g of copper powder. Under stirring conditions, heat until the liquid boils, and control the temperature so that 1 / 3 of the nitrobenzene is partially condensed on the air condenser. The water generated by the reaction is distilled out together with a small amount of nitrobenzene and iodobenzene, and condensed by a condenser. The distillate is dried with a small amount of anhydrous sodium sulfate to remove moisture, and then the solution is returned through a separatory funnel, and the heating reaction is continued for about 24h. After the reaction mixture was slightly cooled, it was transferred to a 150mL flask, and the nitrobenzene and slightly excess diphenylamine were distilled off with steam. Cool the reaction mixture, filter out the precipitate, wash twice with deionized water, tr...

Embodiment 2

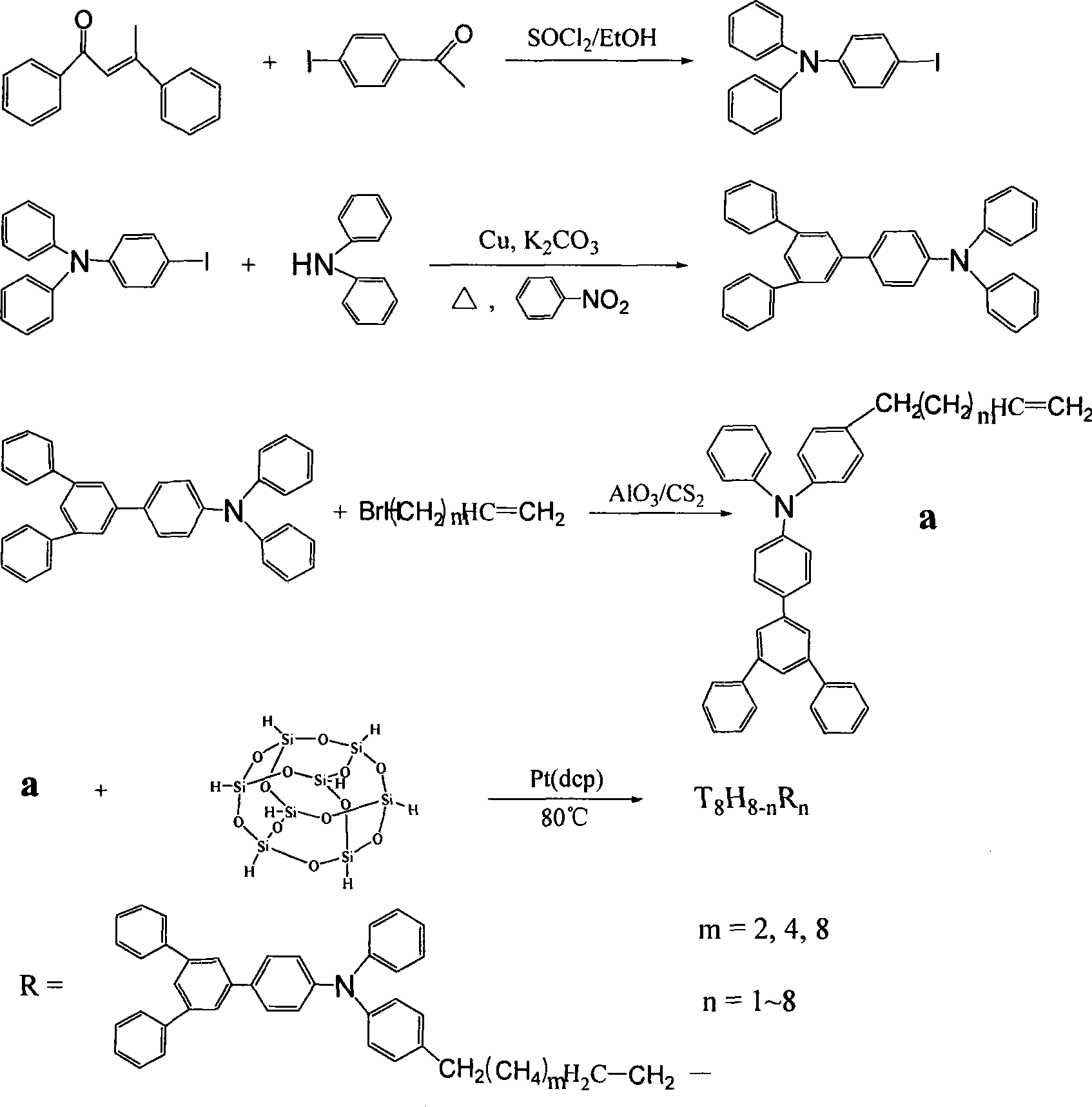

[0026] Add 40mmol substituted chalcone, 40mmol p-iodoacetophenone, and 50mL ethanol to a 250mL three-necked bottle, slowly add 15mL thionyl chloride dropwise under stirring at room temperature, after the dropwise addition, reflux for 2.0h, add saturated sodium carbonate to The solution is neutral. The resulting solution was extracted with dichloromethane, washed twice with deionized water, dried over anhydrous sodium sulfate, filtered to remove sodium sulfate, and rotary evaporated to remove dichloromethane. Add 15mL of ethyl acetate and 15mL of ethanol to the residue, cool and stand until a solid precipitates, and filter to obtain a crude product, which is recrystallized from a mixed solution of ethyl acetate / ethanol to obtain a light yellow solid 4'-iodine-1,3. 5-Triphenylbenzene, 47% yield.

[0027] Add 5mmol 4'-iodo-1,3,5-triphenylbenzene, 10mmol diarylamine, 0.5mmol cuprous chloride, 0.5mmol1 to a 250mL four-necked bottle equipped with a thermometer, a mechanical stirrer...

Embodiment 3

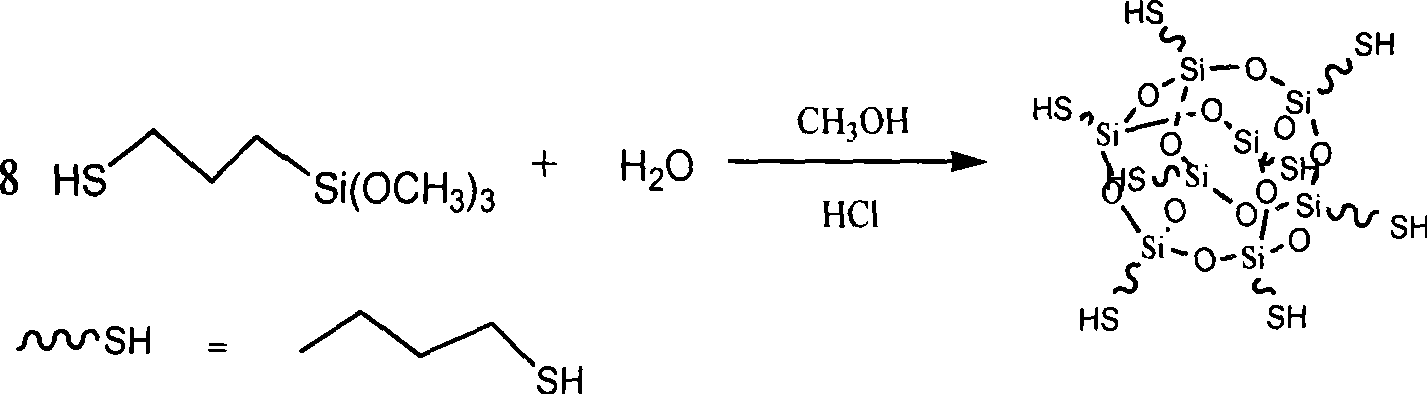

[0032] Synthesis of mercapto POSS: 196.300g (1.0mol) of γ-mercaptopropyltrimethoxysilane, 800mL of methanol, 55mL of distilled water and an appropriate amount of concentrated hydrochloric acid are used to adjust the pH value to 3.0, and then added to the In a 1500mL three-neck flask, under the protection of nitrogen, the reaction was carried out at a constant temperature of 60°C for 48h. Then stop heating and cool to room temperature, filter the product precipitated by the reaction, and wash the product with cyclohexane.

[0033]

[0034] 1.67g (0.01mol) of carbazole, 0.02g of tetrabutylammonium bromide and 0.70g of sodium hydroxide were dissolved in 15mL of ethyl acetate, and 1.49g of 1-bromo-5-pentene was added under stirring After stirring for 24 hours, the solvent was distilled off under reduced pressure, and then 25 mL of deionized water was added to precipitate the product N-(n-1-pentene)carbazole, filtered and washed with deionized water at the same time.

[0035] D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com