Novel process for synthesizing polyatomic alcohol ester by lipase catalysis

A polyol ester, lipase technology, applied in the direction of organic chemistry, petroleum industry, lubricating composition, etc., can solve the problems of poor selectivity, harmful catalysts, and many by-products, etc., to improve reaction activity and stability, and mild reaction conditions. , the effect of eliminating negative effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

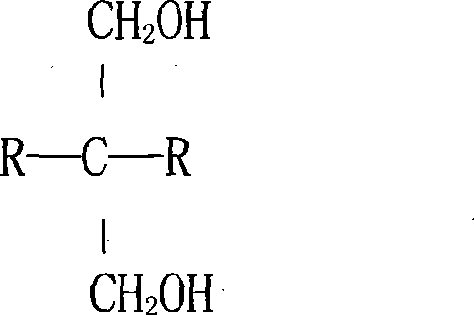

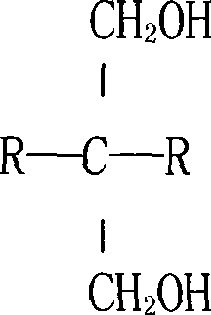

Method used

Image

Examples

Embodiment 1

[0031] Methyl oleate and trimethylolpropane (13.57g) with a molar ratio of 3.1:1 were added to a rotary evaporator, and immobilized lipase Novozym 435 with 10% of the mass of methyl oleate was added, and trimethylolpropane tert-butanol with 350% propane quality, the transesterification reaction is first carried out at 20KPa vacuum degree, 40°C, 200 rpm for 8h; then, tert-butanol is distilled at 5KPa vacuum degree, 40°C temperature; Next, the transesterification reaction was continued at 5KPa vacuum degree, 40° C., and 200 rpm for another 24 hours, and the yield of trimethylolpropane oleate was 95.8%.

Embodiment 2

[0033] Methyl oleate and neopentyl glycol (18.43 g) with a molar ratio of 2.1:1 were added to a rotary evaporator, and immobilized lipase Novozym 435 with 10% of the mass of methyl oleate was added, and neopentyl For tert-butanol with a diol quality of 300%, the transesterification reaction is first carried out at 20KPa vacuum, 40°C, and 200 rpm for 8 hours; then, tert-butanol is distilled at 5KPa vacuum and 40°C; Secondly, the transesterification reaction was continued at 5KPa vacuum degree, 40° C., and 200 rpm for another 20 hours, and the yield of neopentyl glycol oleate was 96.7%.

Embodiment 3

[0035] The rapeseed oil methyl ester and trimethylolpropane (13.57g) that the molar ratio is 3.5:1 join in the rotary evaporator, and add the immobilized lipase Novozym 435 of 10% of the rapeseed oil methyl ester mass, and three Methylol propane quality 300% tert-butanol, the transesterification reaction is first carried out at 20KPa vacuum degree, 40°C, 200 rpm, and lasts for 8h; then, tert-butyl alcohol is distilled at 5KPa vacuum degree, 40°C temperature Alcohol; Secondly, the transesterification reaction was continued at 5KPa vacuum degree, 40°C, 200 rpm, and continued for another 24h, and the yield of trimethylolpropane rapeseed oil fatty acid ester was 92.3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com