Preparation method of immobilized lipase used for grease hydrolysis

An immobilized lipase, oil hydrolysis technology, applied in directions such as immobilization on/in organic carriers, fermentation, etc., can solve the problems of increasing environmental control costs, unbearable actual production, high price, etc. The effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Dissolve cellulose acetate in a dimethylacetamide / acetone mixture with a volume ratio of 3:2, stir and dissolve at room temperature to form a homogeneous solution with a concentration of 130 g / L, and let stand to remove air bubbles. obtain spinning solution;

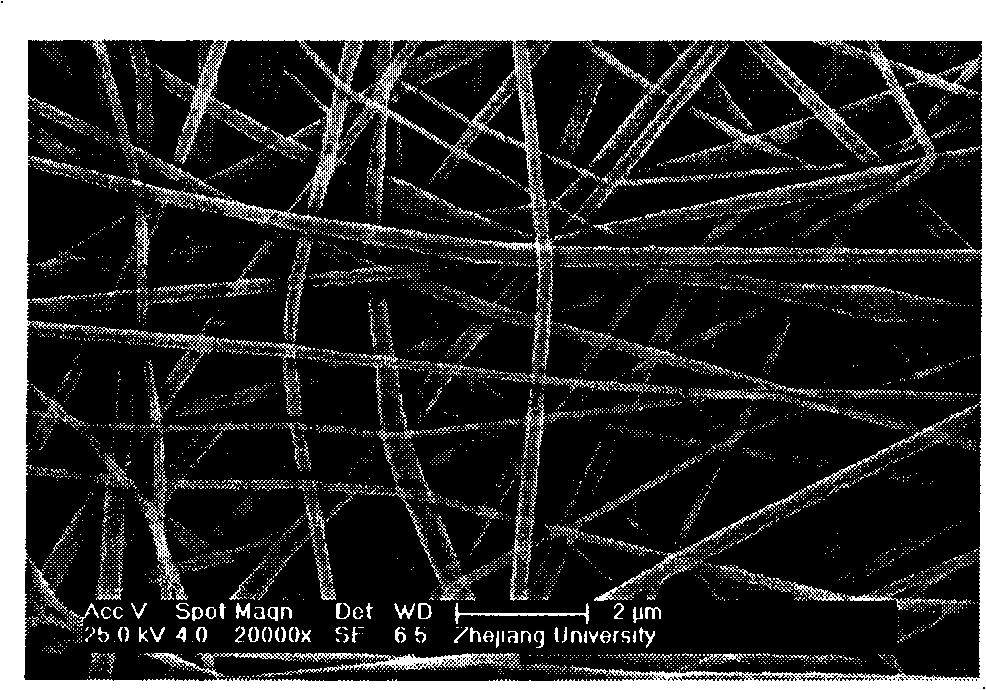

[0024] 2) carry out electrospinning with the spinning solution that makes in step 1), spinning flow rate 1mL / h, spinning voltage is 17kV, and the distance from nozzle to receiving plate is 15cm, makes cellulose acetate superfine fiber film, SEM photo see figure 1 ;

[0025] 3) Place the cellulose acetate microfiber membrane in an ethanol solution of potassium hydroxide with a concentration of 0.5M, soak for 3 hours, take out the membrane after the reaction is completed, rinse it with deionized water several times, and dry it for use;

[0026] 4) Soak the cellulose acetate microfiber membrane obtained in step 3) with absolute ethanol, then immerse in epichlorohydrin, take it out after reacting at 37°C for 3 ho...

Embodiment 2

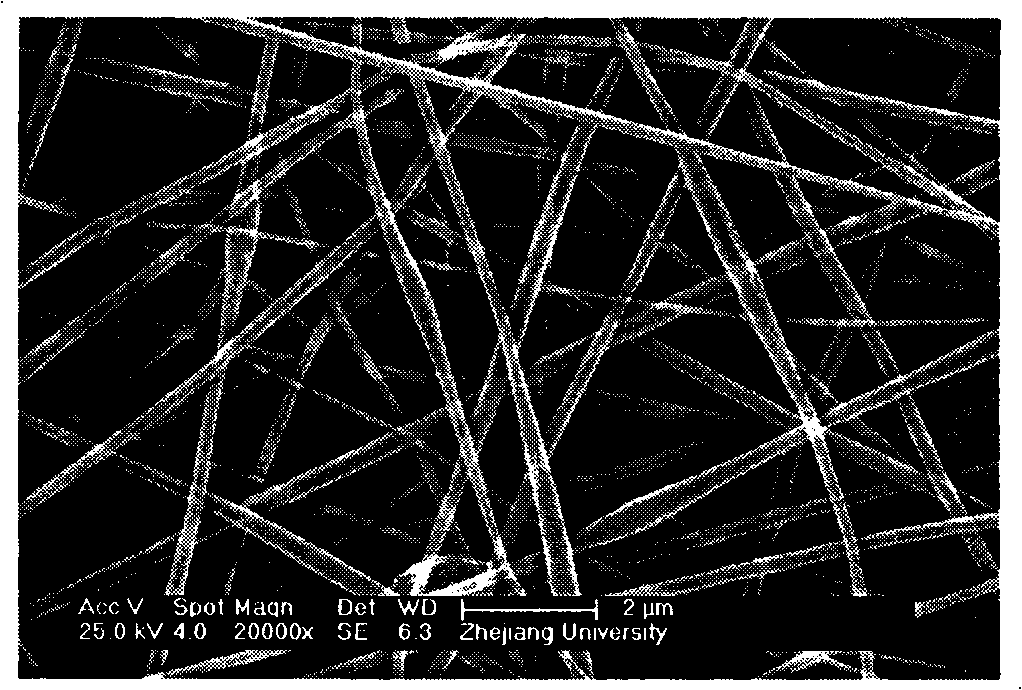

[0030] The steps are the same as in Example 1, but in step 1), cellulose acetate butyrate is used instead of cellulose acetate, and the enzyme loading is 17 mg enzyme / g membrane. Electron micrographs of cellulose acetate butyrate microfiber membranes are shown in figure 2 .

[0031] The prepared cellulose acetate butyrate microfiber membrane immobilized lipase was used for soybean oil hydrolysis, the activity was 267U / g immobilized enzyme; for castor oil hydrolysis, the activity was 256U / g immobilized enzyme; For the hydrolysis of seed oil, the activity is 268U / g immobilized enzyme; for the hydrolysis of peanut oil, the activity is 264U / g immobilized enzyme; for the hydrolysis of cottonseed oil, the activity is 237U / g immobilized enzyme; for the hydrolysis of rice bran oil, the activity is 248U / g immobilized enzyme; for algae oil hydrolysis, the activity is 249U / g immobilized enzyme; for the mixed oil hydrolysis of soybean oil and castor oil with a volume ratio of 1:1, the a...

Embodiment 3

[0033]1) Dissolve cellulose acetate butyrate in a dimethylacetamide / acetone mixture with a volume ratio of 1:1, stir and dissolve at room temperature to form a uniform solution with a concentration of 20g / L, and let it stand to remove air bubbles to obtain spinning solution;

[0034] 2) Electrospinning is carried out with the spinning solution prepared in step 1), the spinning flow rate is 5mL / h, the spinning voltage is 10kV, and the distance from the nozzle to the receiving plate is 10cm, and cellulose acetate butyrate superfine fibers are obtained membrane;

[0035] 3) Place the cellulose acetate butyrate ultrafine fiber membrane in an ethanol solution of potassium hydroxide with a concentration of 1M, soak for 1 hour, take out the membrane after the reaction is completed, rinse it several times with deionized water, and dry it for use;

[0036] 4) Soak the cellulose acetate butyrate superfine fiber membrane obtained in step 3) with absolute ethanol, then immerse in epichlo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com