Preparation technology of multi-purpose silicon micro-nano structure

A technology of micro-nano structure and nano-structure, applied in the field of new material technology and nano-materials, can solve the problems of reduced silicon nano-structure preparation efficiency, difficulty in large-area silicon micro-nano structure preparation, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

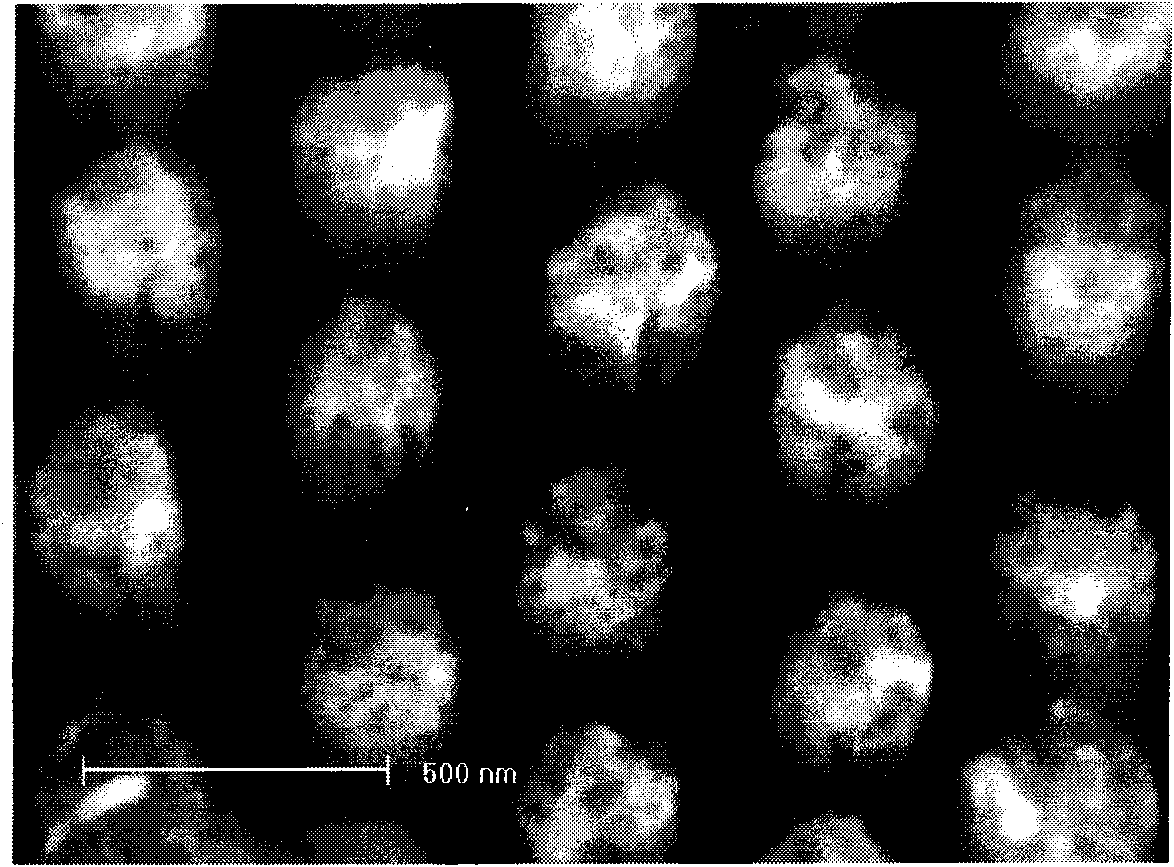

Embodiment 1

[0021] Coat photoresist on the clean silicon surface, and electron beam exposure will accurately copy the nanostructure pattern on the photolithographic mask on the clean silicon wafer surface coated with photoresist, and dissolve the unnecessary photoresist in the developing solution to obtain The resist-protected pattern required for etching has a line width of 100nm. After using high vacuum thermal evaporation technology to deposit a layer of 50nm thick metal silver film on the surface of the treated silicon wafer, the silicon wafer is soaked in the photoresist stripping solution, and the resist on the surface of the silicon wafer is covered on it. silver film removal. Immediately thereafter the wafer was immersed in HF+H 2 o 2 +H 2 O corrosion solution in a closed container, 25 degrees Celsius for 10 minutes. An array of silicon nanostructures is obtained. The samples were then soaked in concentrated nitric acid solution for at least one hour to remove the silver film...

Embodiment 2

[0023] Coat photoresist on the clean silicon surface, and electron beam exposure will accurately copy the nanostructure pattern on the photolithographic mask on the clean silicon wafer surface coated with photoresist, and dissolve the unnecessary photoresist in the developing solution to obtain The resist-protected pattern required for etching has a line width of 200nm. After using high vacuum thermal evaporation technology to deposit a layer of 50nm thick metal silver film on the surface of the treated silicon wafer, the silicon wafer is soaked in the photoresist stripping solution, and the resist on the surface of the silicon wafer is covered on it. silver film removal. Immediately thereafter the wafer was immersed in HF+H 2 o 2 +H 2 In an airtight container of O etching solution, treat at 25 degrees Celsius for 10 minutes to obtain a silicon nanostructure array. The samples were then soaked in concentrated nitric acid solution for at least one hour to remove the silver ...

Embodiment 3

[0025] Coat photoresist on the clean silicon surface, and electron beam exposure will accurately copy the nanostructure pattern on the photolithographic mask on the clean silicon wafer surface coated with photoresist, and dissolve the unnecessary photoresist in the developing solution to obtain The resist-protected pattern required for etching has a line width of 800nm. After depositing a 100nm-thick metal silver film on the surface of the treated silicon wafer using high vacuum thermal evaporation technology, the silicon wafer is soaked in a photoresist stripping solution, and the resist on the surface of the silicon wafer is covered on it. silver film removal. Immediately thereafter the wafer was immersed in HF+H 2 o 2 +H 2 In an airtight container of O etching solution, treat at 25 degrees Celsius for 10 minutes to obtain a silicon nanostructure array. The samples were then soaked in concentrated nitric acid solution for at least one hour to remove the silver film on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com