Catalyst for acid and halogen gas treatment and production method thereof

A halogen gas and acid gas technology, applied in separation methods, greenhouse gas capture, chemical instruments and methods, etc., can solve the problems of high energy consumption efficiency, poor efficiency, pollution and other problems of electric heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

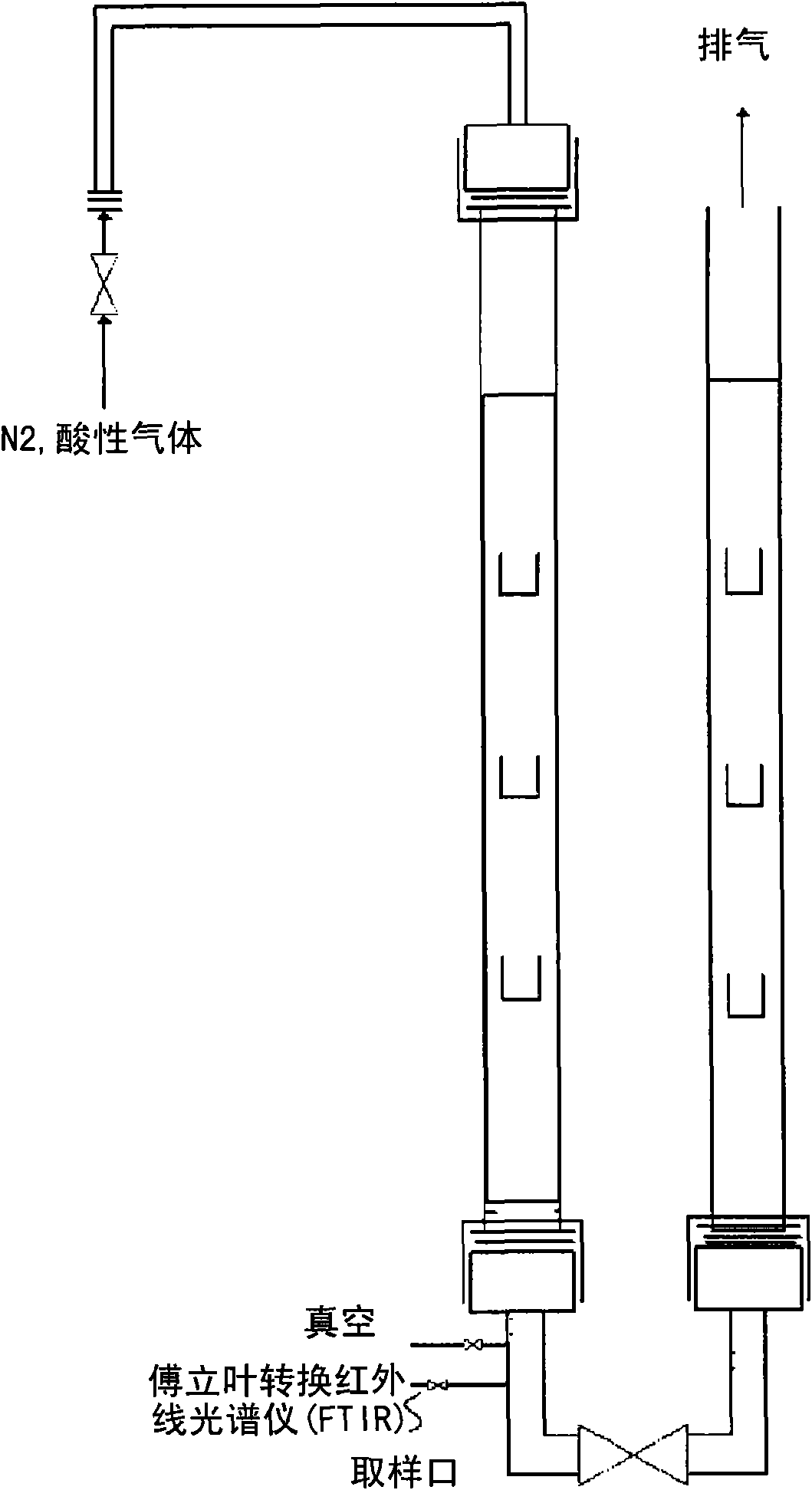

Method used

Image

Examples

specific example

[0020] Representative specific examples of the catalyst of the present invention include the following three series:

[0021] 1. DT-H-001 series:

[0022] Soak saturated potassium carbonate (KCO3) with activated carbon particles 2 CO 3 ), potassium bicarbonate (KHCO 3 ), potassium hydroxide (KOH), sodium carbonate (Na 2 CO 3 ), sodium bicarbonate (NaHCO 3 ), sodium hydroxide (NaOH), lithium carbonate (Li 2 CO 3 ), lithium bicarbonate (LiHCO 3 ) and / or lithium hydroxide (LiOH) and other aqueous solutions or alcohol solutions of about 20-70%, drained after several hours, and then dried at 60-250°C for 2-48 hours to obtain the finished product. According to different gas requirements, prepare different alkaline solutions for soaking to obtain high-efficiency treatment catalysts with different characteristics. It can mainly treat gases such as halogens and hydrogen halides, and can also be used as a catalyst for treating perfluorocarbons (PFCs) gases.

[0023] 2. DT-...

Embodiment 1

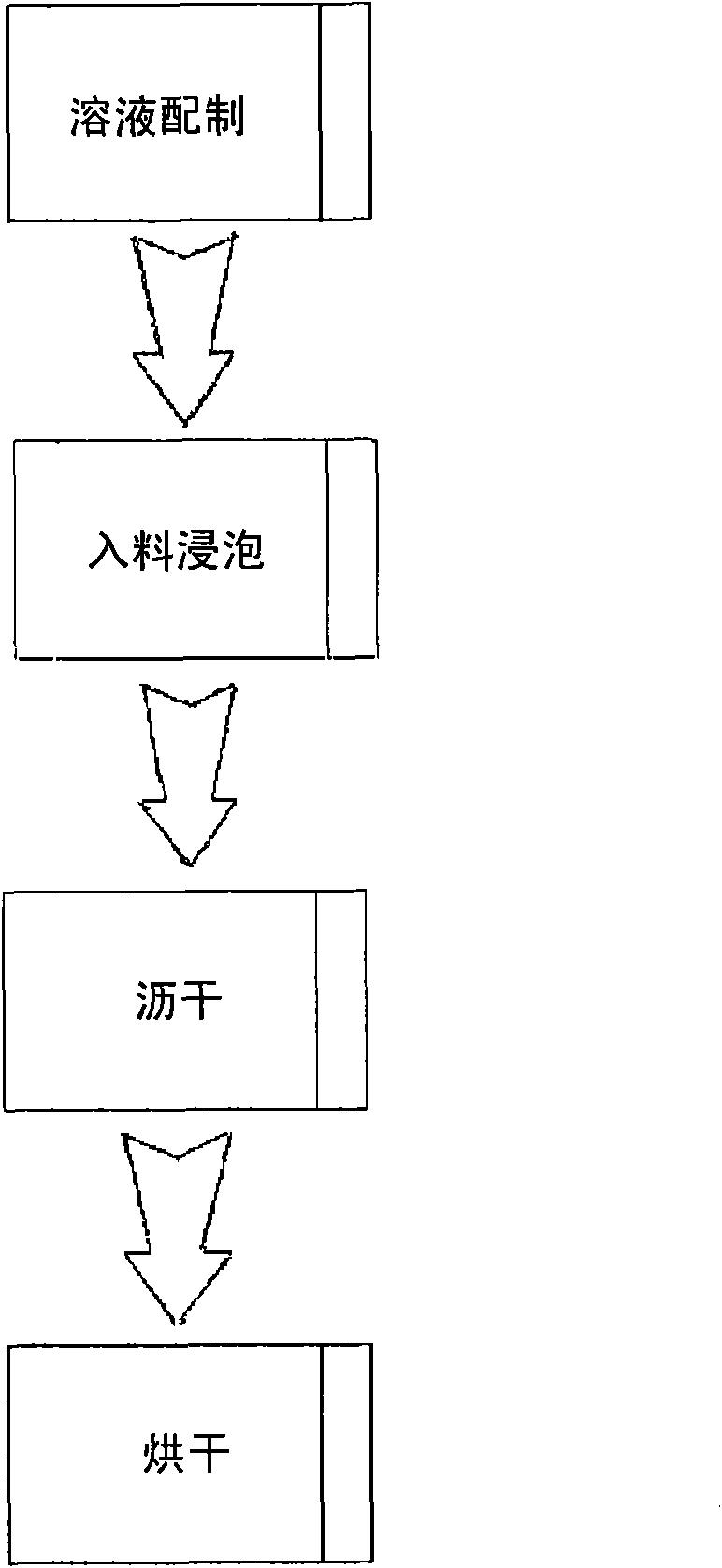

[0031] Example 1: DT-H-001 Series Activated Carbon Immersion Potassium Hydroxide (KOH) / Potassium Carbonate (K 2 CO 3 ) method of manufacture

[0032] one of the above DT-H-001 A series of decomposition catalysts can be manufactured according to the following steps:

[0033] 1. Take 10-30g potassium hydroxide (KOH) and add 10-30g potassium carbonate (KOH) 2 CO 3 ) into 100ml of water and stirred to completely dissolve;

[0034] 2. Add 20-70g of activated carbon and soak at room temperature to 90°C for 2-36 hours;

[0035] 3. Take it out and drain it, put it in an oven and dry it at 60-250°C for 2-48 hours to complete.

Embodiment 2

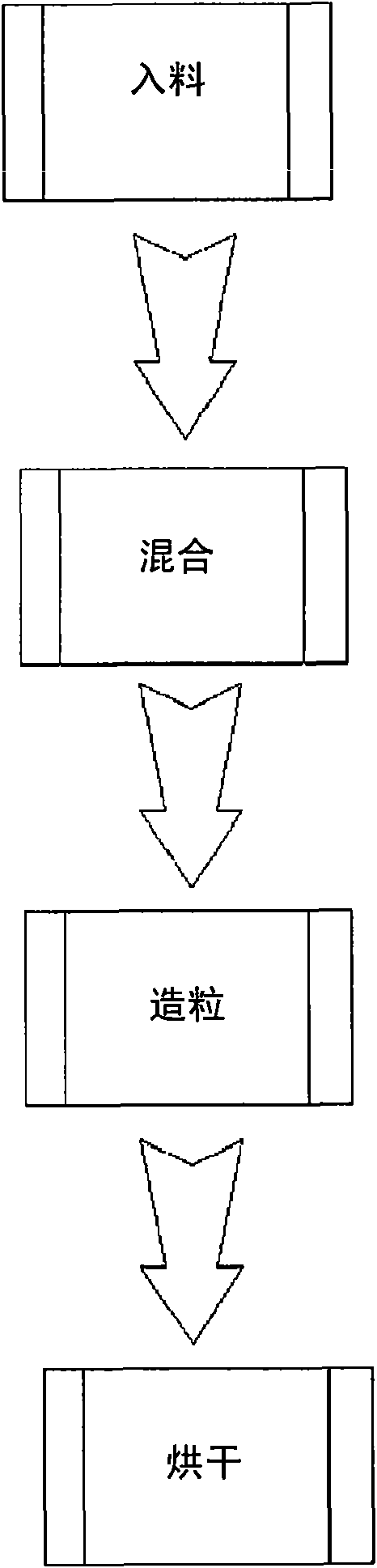

[0036] Example 2: DT-H-002 series of calcium hydroxide (Ca(OH) 2 ), calcium carbonate (CaCO 3 )、 Magnesium oxide (MgO), nickel trioxide (Ni 2 O 3 ), iron oxide monohydrate (Fe 2 O 3 .H 2 O)、 Iron oxide (Fe 2 O 3 ) mixed type of manufacturing method

[0037] one of the above DT-H-002 A series of decomposition catalysts can be manufactured according to the following steps:

[0038] 1. Take 20-80g calcium hydroxide (Ca(OH) 2 ) plus 5-50g calcium carbonate (CaCO 3 ) plus 5-50g magnesium oxide (MgO) plus 2-10g nickel trioxide (Ni 2 o 3 ) plus 2 to 10 g of iron oxide monohydrate (Fe 2 o 3 .H 2 O) add 20~50g iron oxide (Fe 2 o 3 ) plus 30g of silicon dioxide (SiO 2 ) mix and stir evenly;

[0039] 2. Add 10-50ml of 2-40% PVA and 5-20ml of water and stir well;

[0040] 3. Granulate according to the required shape and specification;

[0041] 4. Put it in an oven and dry it at 60-300°C for 6-48 hours to complete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com