Method for quickly generating apatite on surface of titanium and alloy thereof

A technology of apatite and alloy, which is applied in the direction of surface reaction electrolytic coating, electrolytic coating, coating, etc., can solve the problems of reducing the nucleation ability of apatite, reducing the bonding strength between the film layer and the substrate, and achieving the improvement of hydrophilicity Sexuality, easy promotion, fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

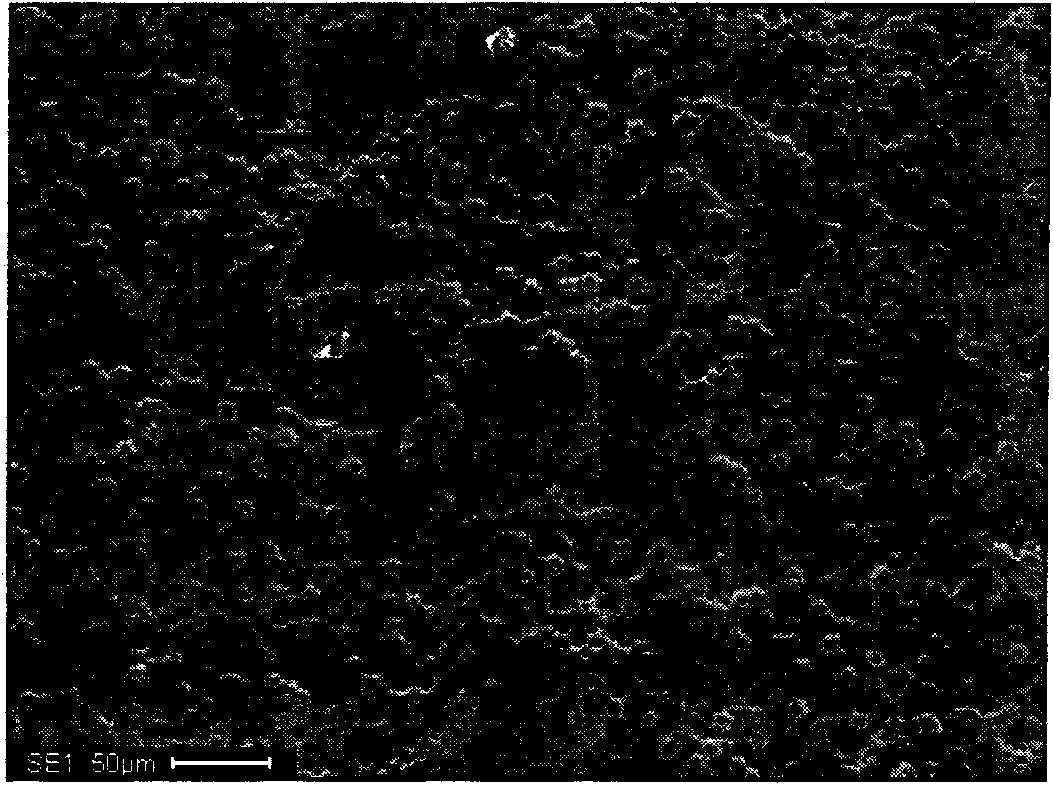

Image

Examples

Embodiment 1

[0028] A method for quickly generating apatite on the surface of titanium and its alloys is to irradiate ultraviolet light on the basis of low-voltage micro-arc oxidation. The method includes the following steps and process conditions:

[0029] Step 1: Low Voltage Micro-arc Oxidation

[0030] (1) Divide 10×10×1mm 3 The titanium sheet is polished to smooth with 180#, 280#, 360#, 600#, 800#, 1000# sandpaper in turn, and then ultrasonically cleaned with 99.5% acetone, 99.7% absolute ethanol, and deionized water for 20 minutes;

[0031] (2) Deionized water is mixed with sodium dihydrogen phosphate and calcium acetate to prepare electrolyte solutions containing phosphate ions and calcium ions, so that the concentration of phosphate ions in the electrolyte solution is 0.02mol / L, and the concentration of calcium ions is 0.10 mol / L;

[0032] (3) With titanium sheet as the anode and stainless steel as the cathode, a DC pulse power supply is used, the micro-arc oxidation voltage is 10...

Embodiment 2

[0037] A method for quickly generating apatite on the surface of titanium and its alloys is to irradiate ultraviolet light on the basis of low-voltage micro-arc oxidation. The method includes the following steps and process conditions:

[0038] Step 1: Low Voltage Micro-arc Oxidation

[0039] (1) Divide 10×10×1mm 3 The titanium sheet is polished to smooth with 180#, 280#, 360#, 600#, 800#, 1000# sandpaper in turn, and then ultrasonically cleaned with 99.5% acetone, 99.7% absolute ethanol, and deionized water for 20 minutes;

[0040] (2) Deionized water is mixed with β-sodium glycerophosphate and calcium acetate to prepare electrolyte solutions containing phosphate ions and calcium ions, so that the concentration of phosphate ions in the electrolyte solution is 0.05mol / L, and the concentration of calcium ions is 0.20mol / L;

[0041] (3) With titanium sheet as the anode and stainless steel as the cathode, a DC pulse power supply is used, the micro-arc oxidation voltage is 200V,...

Embodiment 3

[0046] A method for quickly generating apatite on the surface of titanium and its alloys is to irradiate ultraviolet light on the basis of low-voltage micro-arc oxidation. The method includes the following steps and process conditions:

[0047] Step 1: Low Voltage Micro-arc Oxidation

[0048](1) Polish the Ф4×10mm titanium alloy rod (Ti6Al4V) with 180#, 280#, 360#, 600#, 800#, 1000# sandpaper in sequence until smooth, and then use 99.5% acetone, 99.7% absolute ethanol, Ultrasonic cleaning with deionized water for 20 minutes each;

[0049] (2) Deionized water is mixed with β-sodium glycerophosphate and calcium acetate to prepare electrolyte solutions containing phosphate ions and calcium ions, so that the concentration of phosphate ions in the electrolyte solution is 0.10mol / L, and the concentration of calcium ions is 0.30mol / L;

[0050] (3) Titanium alloy rods are used as anodes, stainless steel is used as cathodes, a DC pulse power supply is used, the micro-arc oxidation vo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com