Cathode material of lithium-ion secondary battery and method for preparing same

A technology for secondary batteries and positive electrode materials, which is applied in the field of positive electrode materials for lithium-ion secondary batteries and its preparation. It can solve the problem of the uniformity of material crystallization, the difficulty in precise control of particle shape and particle size distribution, and the violation of the sustainable development strategy. , many heat treatment steps, etc., to achieve good electrochemical performance, less steps, and uniform surface coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]The main preparation steps of this embodiment are:

[0039] a) Weigh the reaction raw material LiOH·H respectively according to the mole fraction ratio of Li:(Ni+Co):B is 1.03:0.97:0.03 2 O, Ni 0.8 co 0.2 (OH) 2 and H 3 BO 3 , for grinding and thorough mixing;

[0040] b) put the mixture obtained in step (a) into a flat-bottomed crucible, put it into a cylindrical high-temperature furnace that adopts electric heating, and heat it; The current heats up, and when the temperature reaches 500°C, keep it warm for pretreatment, and the pretreatment time is 5 hours; cool the flat-bottomed crucible to below 100°C with the furnace, take out the pre-burned raw materials, put them into a mortar and grind them again;

[0041] c) Put the raw material ground in step (b) into a rotary muffle furnace, heat up with a constant current, and feed oxygen at the same time, with a pressure of 1 standard atmosphere. When the temperature reaches 750°C, keep warm to carry out high-temperat...

Embodiment 2

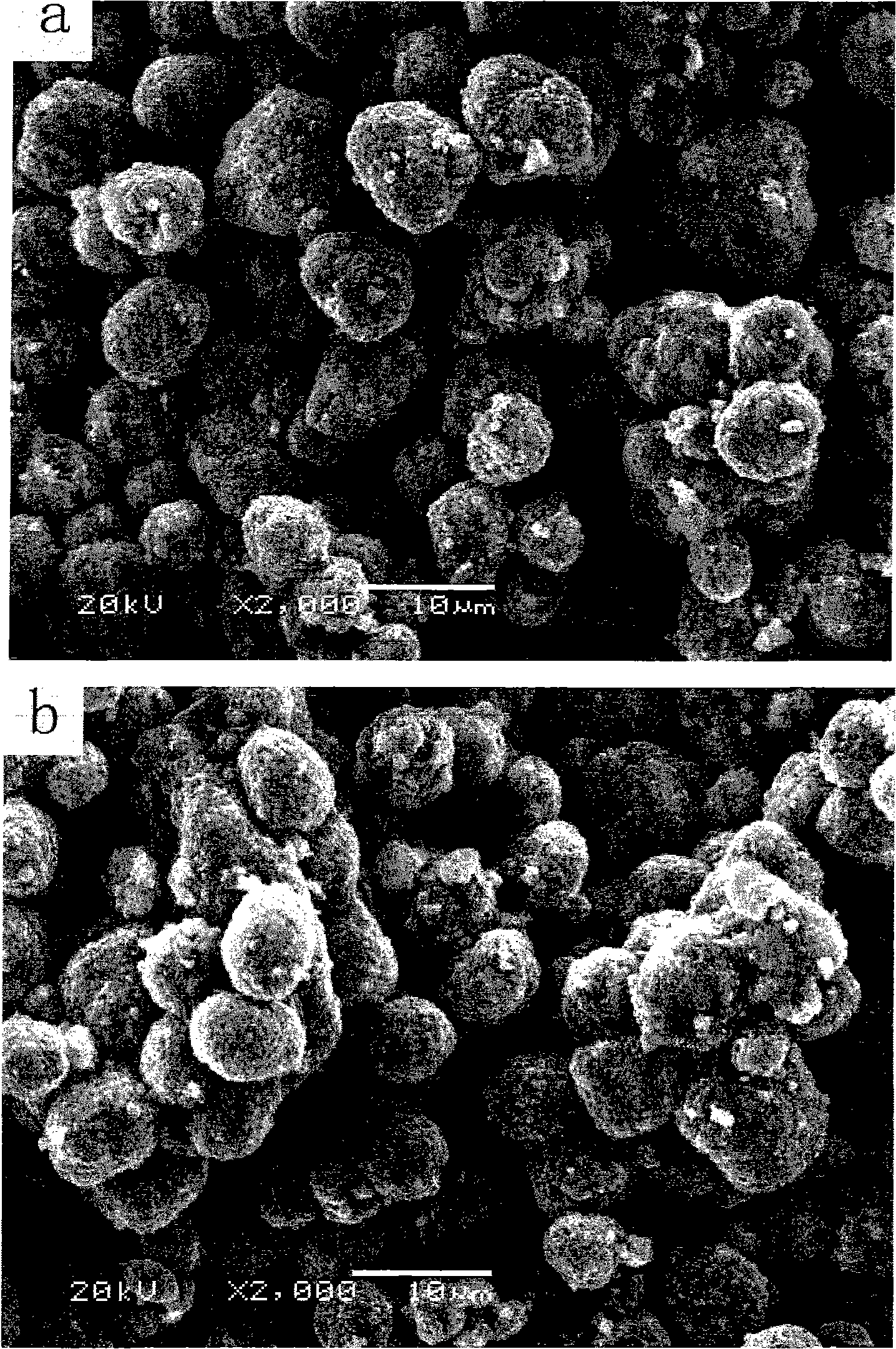

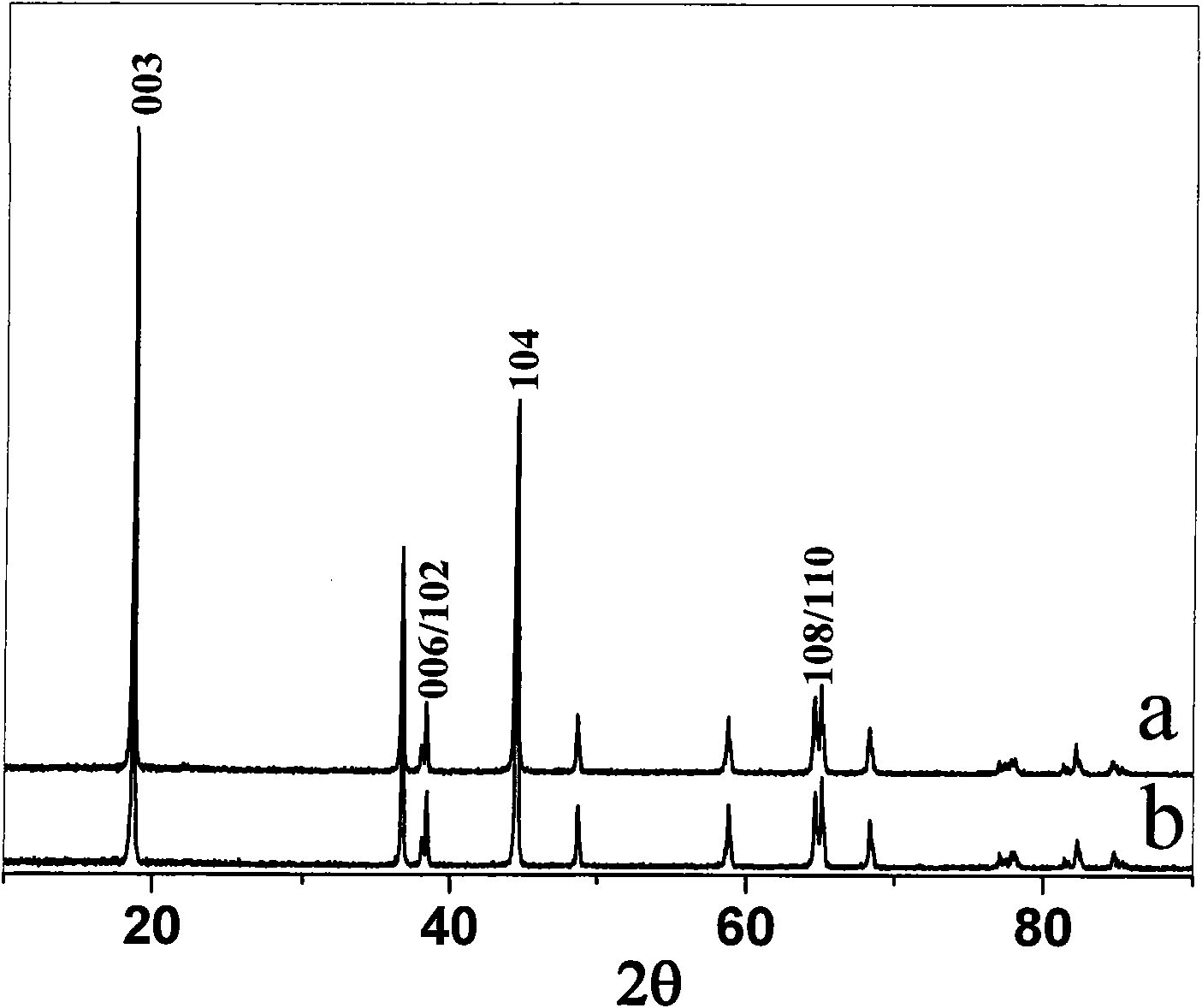

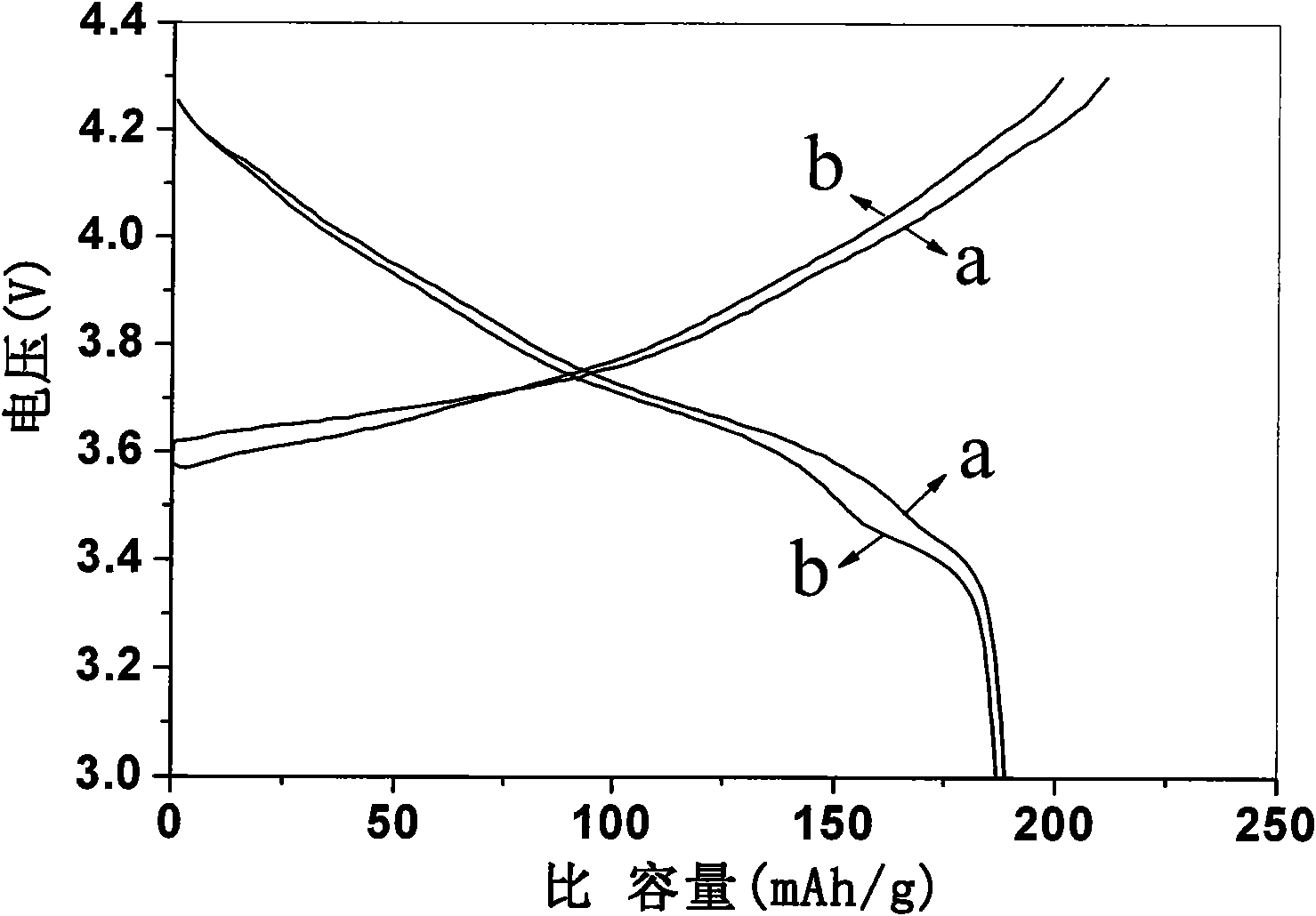

[0046] The preparation step of this embodiment is the same as that of Example 1, except that the Ni 0.8 co 0.2 (OH) 2 Change to LiNi 0.8 co 0.2 o 2 , and LiOH·H 2 The amount of O is changed to H 3 BO 3 Half of the molar number of the dosage, the obtained boron-doped lithium nickel cobalt oxide material is LiNi 0.776 co 0.194 B 0.03 o 2 , and its scanning electron microscope image is as figure 1 Shown in b, its average particle diameter is basically the same as that of Example 1, and the X-ray diffraction pattern of this material is as figure 2 Shown in curve b. Use this cathode material to make a simulated battery to test its capacity and cycle performance, such as image 3 and Figure 4 As shown in the curve b, the first discharge specific capacity is 188.8mAh / g under the 3.0-4.3V, 0.5C rate charge and discharge system, and the capacity retention rate after 50 cycles at 1C rate is 93.3%.

Embodiment 3

[0048] The raw materials used in this embodiment are the same as in Example 1, except that the mol ratio of Li in step (1): (Ni+Co): B is changed to 1.03: 0.99: 0.01; the holding temperature in step (2) is changed to 400°C , the holding time was changed to 8h; the holding temperature in step (4) was changed to 800°C, and the holding time was 6h. Other steps were the same as in Example 1, and the positive electrode material prepared at last was LiNi 0.792 co 0.198 B 0.01 o 2 . Using this cathode material to make a simulated battery, its capacity and cycle performance are as follows: Figure 5 and Figure 6 As shown, the first discharge specific capacity is 187.5mAh / g under the 3.0-4.3V, 0.5C rate charge-discharge system, and the capacity retention rate after 50 cycles at 1C rate is 89%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Tap density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com