Solar battery with soft copper, indium, gallium and selenium film

A technology of solar cells and copper indium gallium selenide, applied in circuits, electrical components, photovoltaic power generation, etc., can solve problems affecting battery performance, difficult to install or carry, peeling off, etc., to achieve wide application and promotion, improve light conversion efficiency, The effect of simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

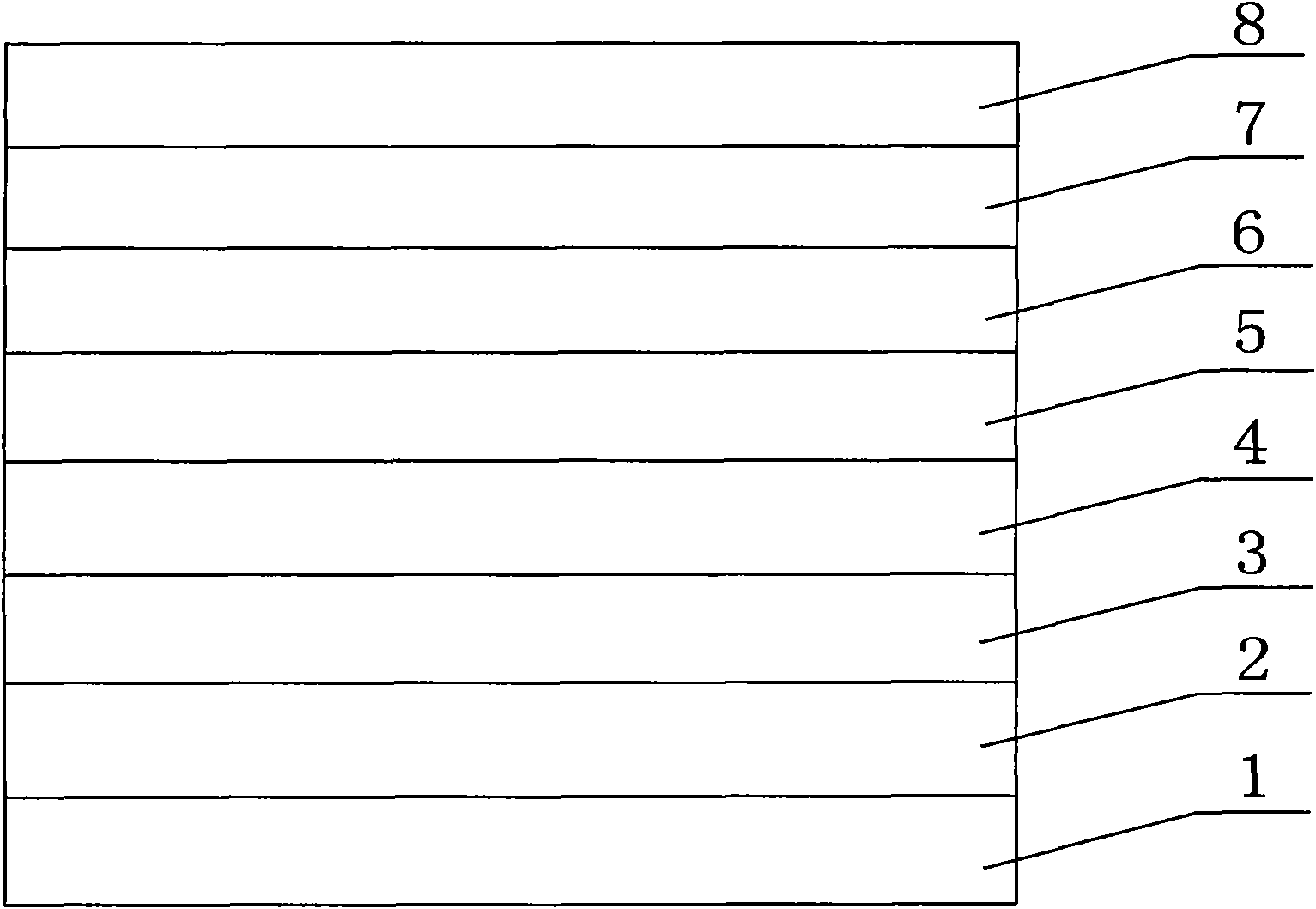

[0027] The following specific examples of preparing copper indium gallium selenium thin film solar cells with polyimide as a flexible substrate will further elaborate the present invention, and its specific preparation is as follows:

[0028] (1) Clean the flexible polyimide substrate 1 of 5cm×5cm×100um with pure acetone, absolute ethanol and deionized water for 15 minutes, and then dry it with pure nitrogen for later use;

[0029] (2) The above-mentioned cleaned polyimide flexible substrate 1 is placed in the vacuum chamber of the magnetron sputtering system, and in a pure argon atmosphere, it is glow-treated for 15 minutes with a plasma with a power of 50W;

[0030] (3) Under the pressure of 1.0Pa and the radio frequency power of 200W, the sodium-containing silicate target (Na 2 O·CaO·5SiO 2 ) target material for 50 minutes, on the polyimide flexible substrate 1, the thickness of the film layer is deposited on the polyimide flexible substrate 1, and the alkali silicate film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com