Cadmium telluride film solar cell and preparation method thereof

A technology of solar cells and cadmium telluride, which is applied in the field of solar cells, can solve problems such as environmental pollution, large amount of toxic cadmium, and hazards to operators, and achieve the effect of avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

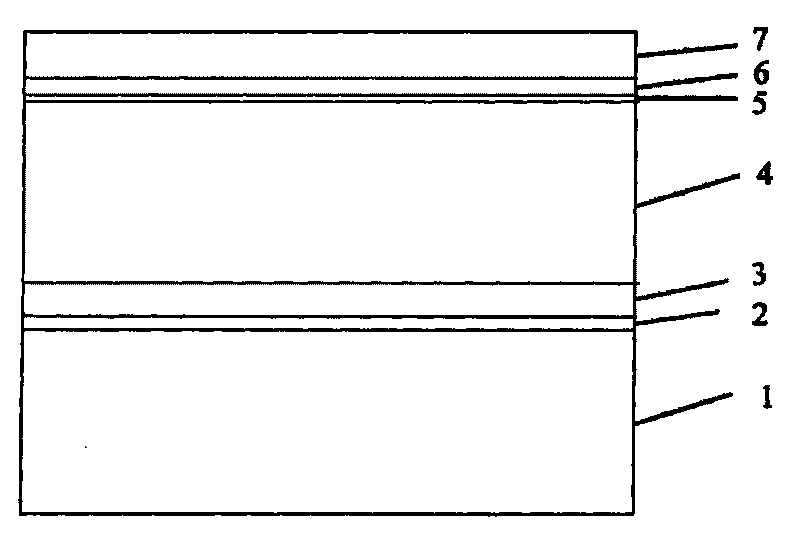

[0028] The preparation method of the present invention is:

[0029] (1) Use low toxicity compound cadmium as the cadmium source, use sulfur or sulfide as the sulfur source, use tellurium or telluride as the tellurium source, and carry out a molar ratio of cadmium source to sulfur source or tellurium source of 1:1 to 1:50. chemical reaction to prepare cadmium sulfide and cadmium telluride particles with uniform particle size; the cadmium sulfide and cadmium telluride particles are prepared by high temperature pyrolysis method or hydrothermal synthesis method, wherein the cadmium source is cadmium oxide, cadmium oleate, ten Any one of cadmium octaate, cadmium hexadecate, cadmium chloride, cadmium sulfate, and cadmium nitrate; the sulfur source adopts long-chain organic acid or organic amine-treated sulfur in the high-temperature pyrolysis method, and the tellurium source adopts Tellurium treated with long-chain organic acids or organic amines, and the high-boiling organic solven...

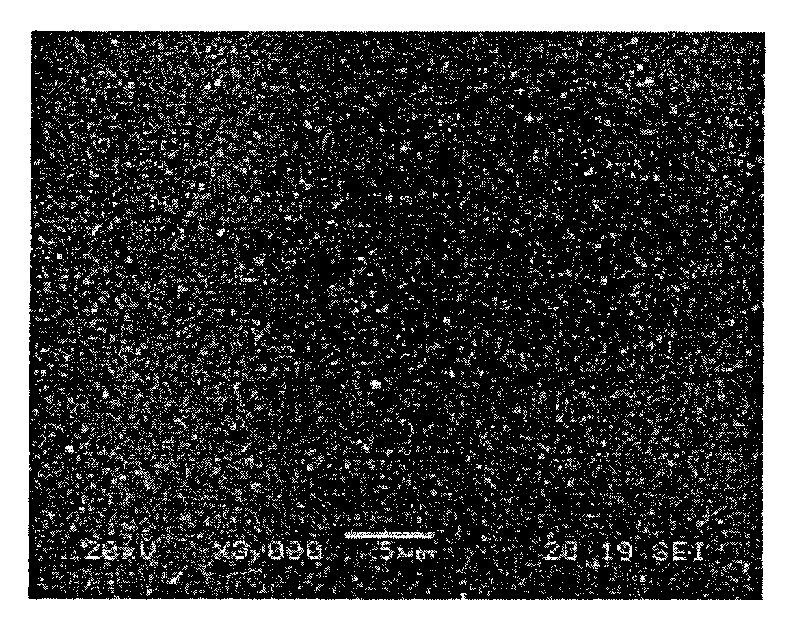

Embodiment 1

[0035]Get 3mmol of cadmium oxide, 5mmol of oleic acid, 80g of octadecene mixed into a 500mL three-necked flask, heated to 240°C under nitrogen environment until the solution is completely uniform, get 3mmol of sulfur powder, 36mmol of oleylamine and 100mL of octadecene and heated to 180 The light yellow solution obtained at ℃ was added to the above-mentioned three-necked flask, and then the temperature was set to 220 ℃ for growth, and the reaction was performed for 1 hour to obtain cadmium sulfide.

[0036] The above cadmium sulfide product is added to a mixed solution of 90 mL of acetone and 10 mL of methanol, and purified by centrifugation for 3 to 5 times.

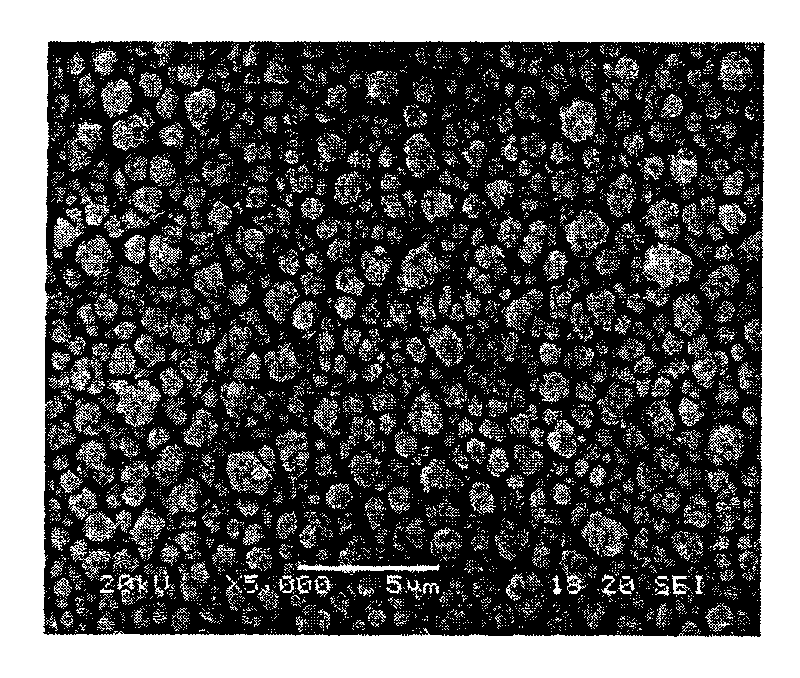

[0037] Take 3mmol of cadmium oleate, 1mmol of oleic acid, and 80g of octadecene mixed into a 500mL three-neck flask, heated to 280°C under nitrogen atmosphere until the solution is completely uniform, and heated by taking 150mmol tellurium powder, 36mmol L octadecylamine and 100mL octadecene. The light yellow solution o...

Embodiment 2

[0048] Get 3mmol cadmium oxide, 5mmol hexadecanoic acid, 80g paraffin mix and put into 500mL three-necked flask, heat to 240 ℃ under nitrogen environment until the solution is completely uniform, get 12mmol sulfur powder 36mmol oleic acid and 100mL octadecene and paraffin mixed solution The light yellow solution obtained by heating to 180 DEG C was added to the above three-necked flask, and then the temperature was set to 220 DEG C for growth, and the reaction was performed for 1 hour to obtain cadmium sulfide.

[0049] Take 3mmol of cadmium octadecanoate, 1mmol of hexadecanoic acid, and 80g of paraffin, mix them into a 500mL three-necked flask, heat to 280°C under nitrogen atmosphere until the solution is completely uniform, take 12mmol of tellurium powder, 36mmol of octadecanoic acid and 100mL of octadecene and heat The light yellow solution obtained at 220° C. was added to the above three-necked flask, and then the temperature was set to 260° C. for growth, and the reaction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com