Method for preparing in-situ therapeutic substance-loaded microcapsules

A therapeutic and microcapsule technology, which is applied in the field of biomedicine and biomaterials, can solve the problem that it is difficult to meet the stable and sustained release of microcapsules, the controllable release and sustained release of drugs are difficult to maintain, and the wall layer of microcapsules collapses. and other issues, to achieve excellent biological safety and controlled drug release, which is conducive to sustained release and adjustable particle size.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The weighing average molecular weight is 50000, and the degree of deacetylation is 83%. Inside the syringe of the electrospinning device;

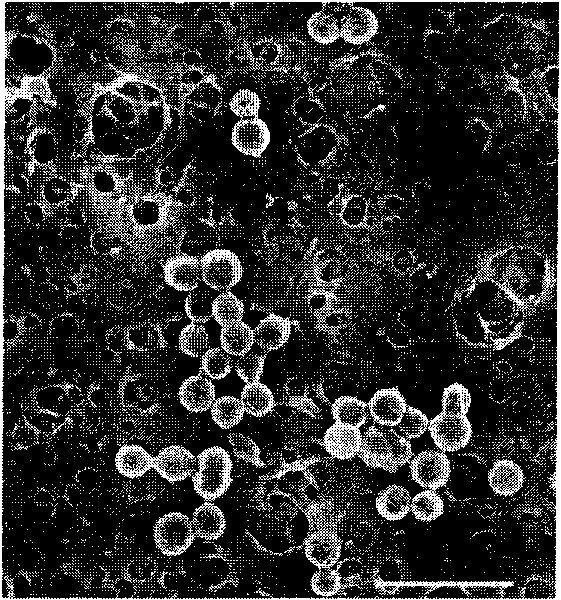

[0031] Dissolve sodium alginate in water to prepare a sodium alginate aqueous solution with a concentration of 12g / L, then place it in a container directly below the needle tip of a hollow metal needle of a syringe, and adjust the distance between the needle tip and the liquid surface of the sodium alginate solution to be 8cm. The solution is grounded with a wire, and continuously stirred at 60 rpm, the hollow metal needle is connected to a 10kV DC voltage, and the chitosan solution in the syringe is pushed out at a speed of 0.10 ml / hour, and electrostatically sprayed, containing cyclosporine A Under the action of high-voltage electrostatic electric field, the chitosan solution instantly forms a mist of gel particles, which falls into the sodium alginate solution to form chitosan gel particles with sodium alginate as the capsule wal...

Embodiment 2

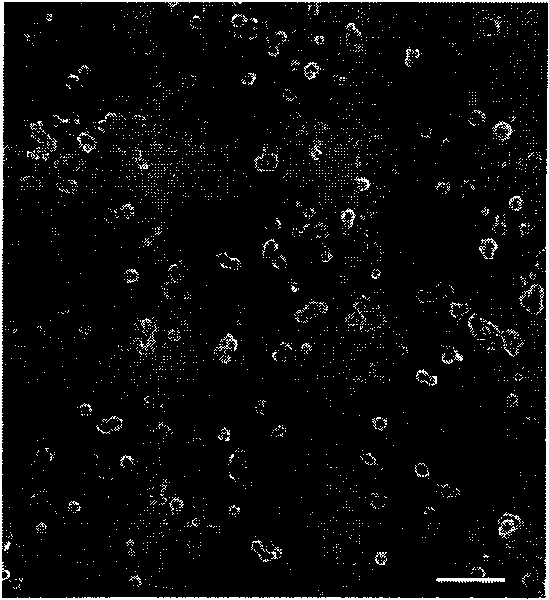

[0033] With the preparation method of Example 1, the difference is: add vascular endothelial growth factor to the chitosan solution, change the DC voltage applied by the metal needle to 15kV, and the distance between the needle tip and the grounded 12g / L sodium alginate receiving solution Change it to 12cm, make microcapsules loaded with vascular endothelial growth factor through high-voltage electrostatic spraying, and observe the morphology of this kind of microcapsules with a scanning electron microscope as attached figure 2 As shown, the microcapsules prepared by this method are nearly spherical nanoparticles.

Embodiment 3

[0035] Sodium alginate was dissolved in water to prepare a sodium alginate aqueous solution with a concentration of 30g / L, and then 0.001g of nano-titanium dioxide with a particle size of 30nm was added, mixed evenly and loaded into the syringe of the electrospinning device;

[0036] Weighing average molecular weight is 250000, and the degree of deacetylation is 86%. , adjust the distance between the needle tip and the liquid surface of the chitosan solution to be 10cm, the solution is grounded with a wire, and continuously stirred at 120 rpm, the hollow metal needle is connected to a DC voltage of 15kV, and the sodium alginate solution in the syringe is injected at a rate of 0.20 ml / hour The speed is pushed out, and electrostatic spraying is carried out. The sodium alginate solution containing nano-titanium dioxide instantly forms a mist of gel particles under the action of a high-voltage electrostatic electric field, and falls into the chitosan solution to form a microcosm wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com