Method for preparing probiotic brown lactobacillus beverage product with large amount of bacteria

A lactic acid bacteria beverage and probiotic technology, applied in dairy products, milk preparations, applications, etc., can solve the problems of poor tolerance, easy inactivation by gastric acid, and low number of probiotics, achieve strong tolerance, restore intestinal The effect of bacterial flora balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

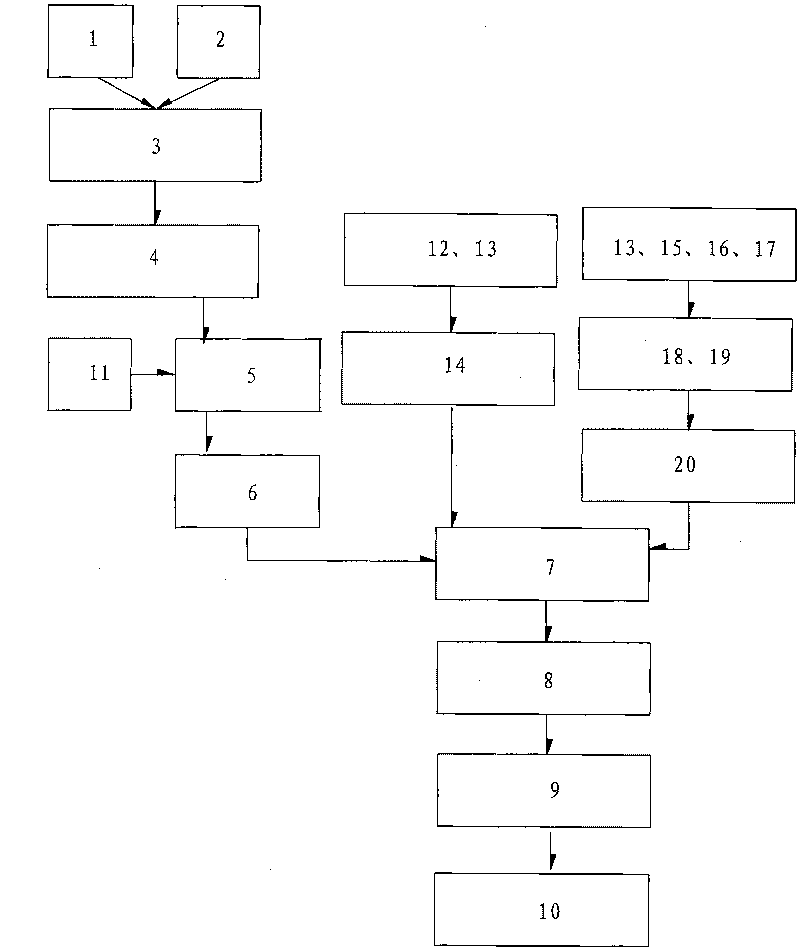

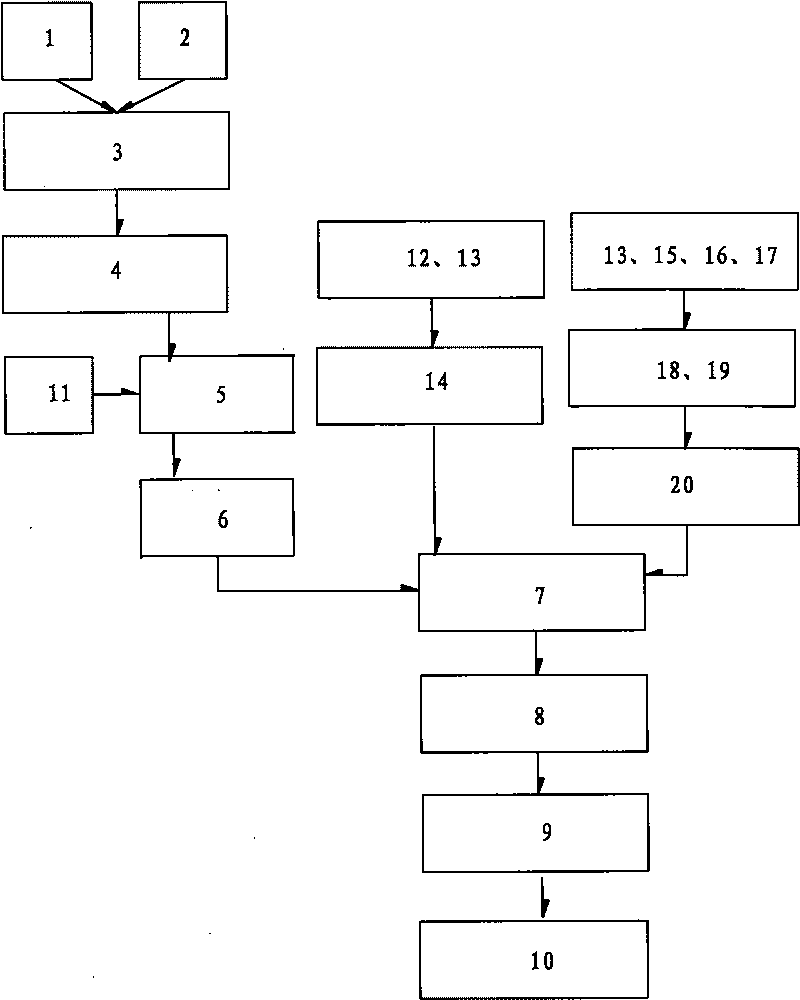

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 is prepared using skimmed milk powder

[0039] All raw materials: skimmed milk powder, glucose, purified water, Lactobacillus casei strains, citric acid, sucrose, fructose syrup, pectin and food flavors are commercially available.

[0040] Equipment for trial production: colloid mill or water-powder mixer, homogenizer, temporary storage tank, sterilizing plate combination, cooling plate, screw pump, constant temperature incubator, PH meter, viscometer and filling machine, etc.;

[0041] Ingredients:

[0042] Skimmed milk powder 10kg, glucose 2kg, purified water 70kg;

[0043] Specific steps:

[0044] 1. Hydration: Restore skim milk powder and purified water to skim milk at a ratio of 1:4~8, and add a certain amount of glucose and the rest of water for hydration. The hydration temperature is 40~50°C, and the hydration time is 30~40min; stirring time And frequency: 30s / 15min; after the hydration is completed, sterilize at 95°C for 5min; obtain the steriliz...

Embodiment 2

[0055] Embodiment 2 is prepared using skimmed milk powder

[0056] 1. Maillard reaction

[0057] Skimmed milk powder 20kg, glucose 6kg, purified water 160kg;

[0058] Hydration temperature: 50-55°C, hydration time: 40-50min; stirring time and frequency: 30sec / 15min; sterilization temperature: 98°C, 5min; stir at 95-98°C, react for 2.0-2.5h; the reaction liquid changes from milky yellow to When the brown color is the end point of the reaction, the Maillard reaction solution is obtained and set aside;

[0059] 2. Probiotic fermentation

[0060] Cool the Maillard reaction solution to 37-38°C, inoculate 0.02-0.03 g of bacteria per 100ml of Maillard reaction solution, inoculate Lactobacillus casei (Lactobacillus casei) bacteria, stir for 10-15 minutes after inoculation, and then inoculate at 37 Ferment at ~38°C for 72 hours. When the pH reaches 3.8-4.0, stop the fermentation, cool to 2-6°C, and obtain the probiotic fermentation broth for later use;

[0061] 3. Post-processing ...

Embodiment 3

[0066] Embodiment 3 is prepared using skimmed milk powder

[0067] Maillard reaction

[0068] Weight ratio: skim milk powder 15kg, glucose 4kg, purified water 120kg; inoculate 0.02-0.025g of bacteria per 100ml of Maillard reaction solution, inoculate Lactobacillus casei (Lactobacillus casei) bacteria, probiotics ferment for 56 hours, and adjust the acidity tartaric acid;

[0069] During base material preparation, beet sugar 4kg, fructose syrup 8kg, pectin 0.4kg, purified water 80kg, all the other are the same as embodiment 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com