Preparation method of compact silicon carbide ceramic

A technology of silicon carbide ceramics and silicon carbide, which is applied in the field of preparation of high-strength and dense silicon carbide ceramics, can solve the problems of complex preparation process, large sintering shrinkage, and low production efficiency, and achieve simple process, short production cycle and high production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A preparation method of dense silicon carbide ceramics, comprising the steps of:

[0026] (1) Prepare the mixture according to the mass percentage and formula listed in Table 1: silicon carbide powder can use a single particle size, or a combination of particle sizes with different size distributions; adding a grain regulator can stabilize the deposition and densify the product. Grain modifiers include silicon nitride, boron and borides (boron nitride, boron carbide, boron), vanadium compounds (such as vanadium carbide, vanadium silicide, vanadium oxide).

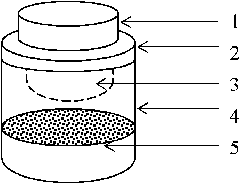

[0027] (2) Add mixed batch 5 in graphite crucible 4, charge height is less than 1 / 4th of crucible depth, cover support body 2 again, place graphite cooling block 1 on support body 2 ( figure 1 ).

[0028] (3) Put the graphite crucible 4 with the mixed ingredients 5, the support body 2 and the graphite cooling block 1 into the intermediate frequency electromagnetic induction furnace together, and evacuate until the p...

Embodiment 7

[0039] It can be seen from Table 3 that the silicon carbide ceramic block 3 prepared by the present invention has a thickness of 3-51 mm, a density greater than 3.15 grams / cubic centimeter, and a three-point bending strength greater than 600 MPa. The porosity is less than 0.05%. For the silicon carbide ceramic product of embodiment 7, observe its structure morphology with SX-2700 scanning electron microscope see figure 2 with image 3 . in figure 2 It is the microstructural structure of 300 times of the original surface of embodiment 7; image 3 It is 25 times the microstructural structure of embodiment 7 perpendicular to the original plane (growth direction). It can be seen from the figure that the material particles are bonded by pure silicon carbide, and the silicon carbide crystal particles are oriented through the crystal preferred orientation, and there are almost no pores.

[0040] Table 3 Test performance of dense silicon carbide ceramic material of the present ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com