New production process for refining crude heparin sodium

A production process and technology of crude heparin, which is applied in the field of refined production process of crude heparin sodium, can solve problems such as difficulty in obtaining high-quality heparin products, large loss of heparin activity, and destruction of heparin structure, and achieve less dosage, less loss of heparin activity, and cracking Gentle and complete effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

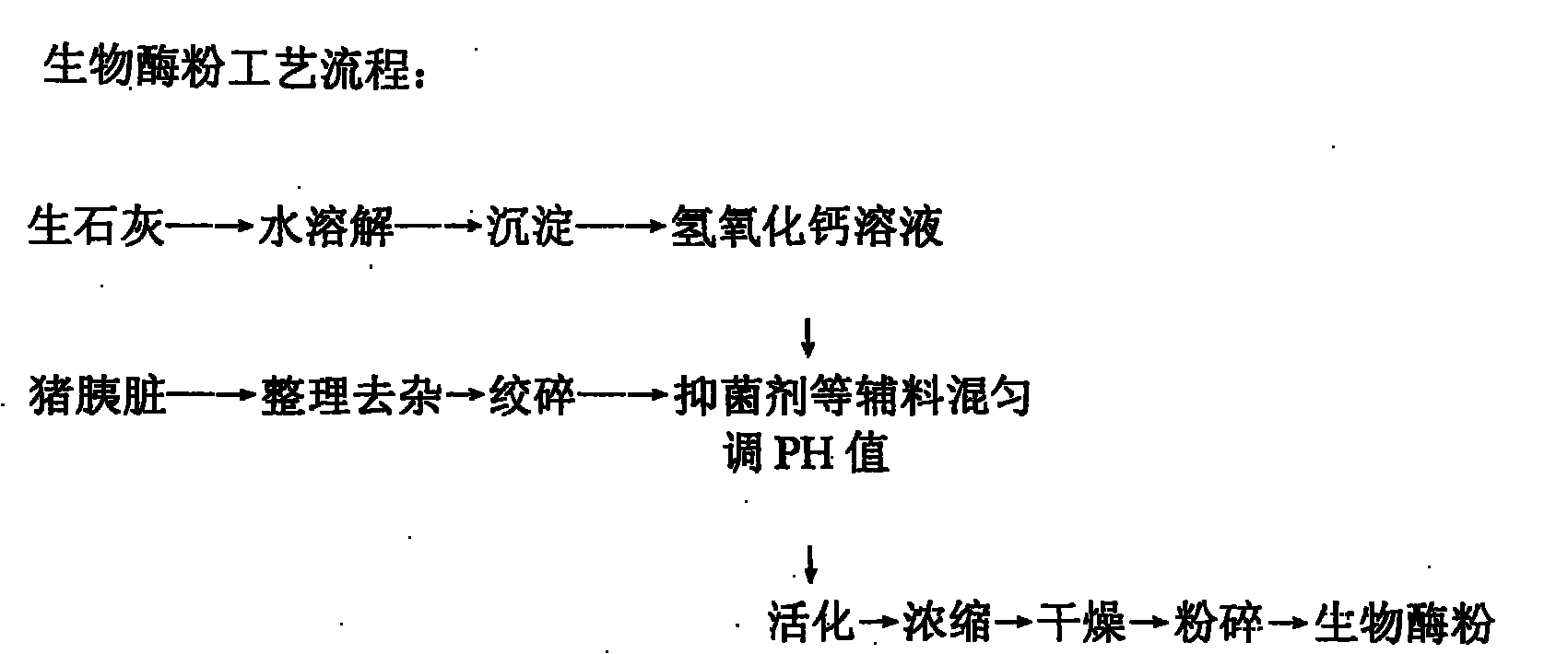

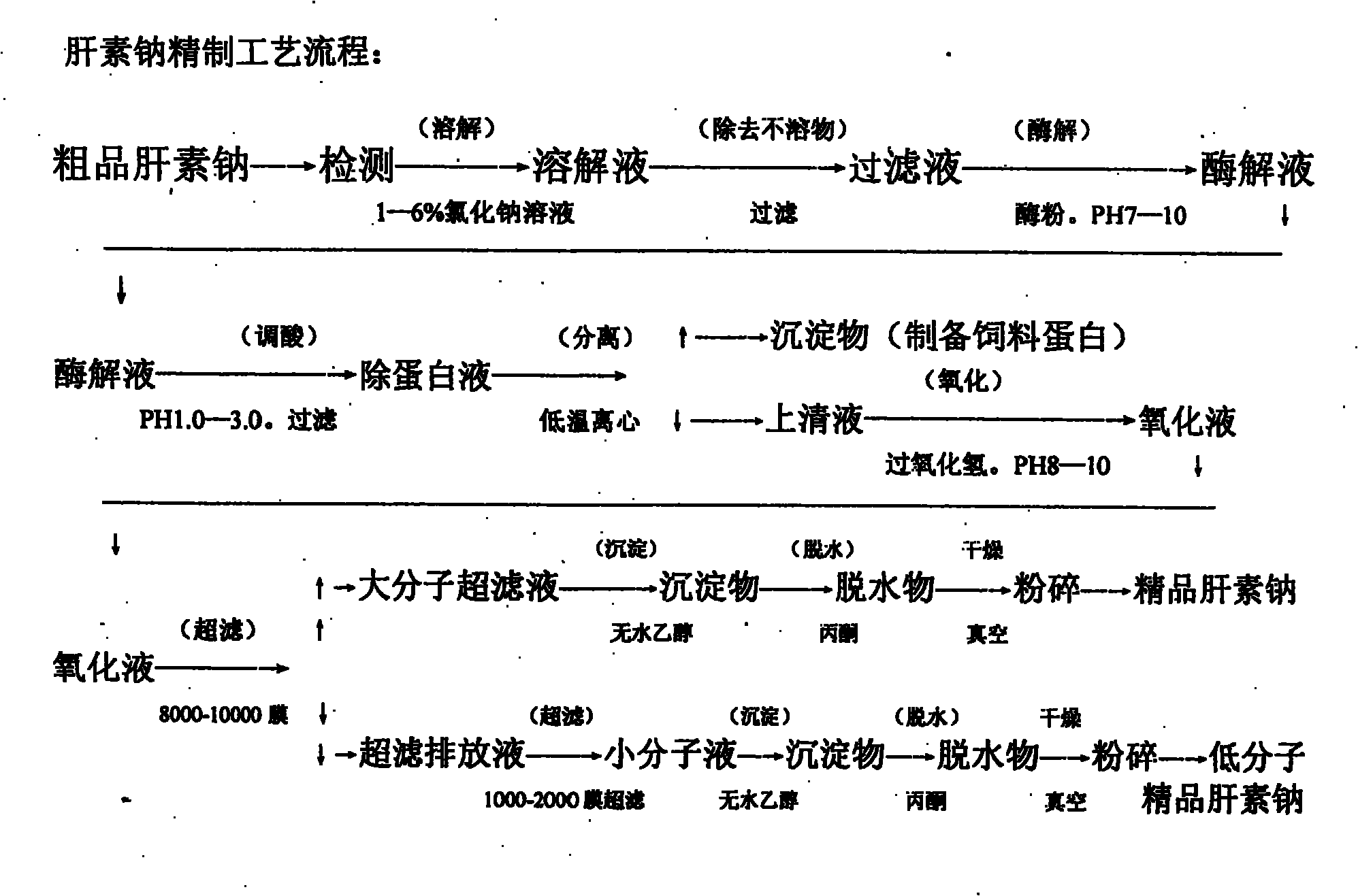

Method used

Image

Examples

Embodiment

[0039] ①Main experimental equipment:

[0040] Ultraviolet spectrophotometer (Shanghai Jingke), centrifuge (Shanghai Anting), stirrer, reaction kettle, vacuum drying oven, analytical balance, electronic balance, PH meter, pipette gun, test tube, beaker and other appliances.

[0041] ②Material:

[0042] Crude heparin sodium (produced by the applicant), heparin standard (China Institute for the Identification of Pharmaceutical and Biological Products), sheep plasma or pig plasma (collected by itself), hydrogen peroxide (analytical pure Chengdu Chemical Reagent Company), biological enzyme powder (applied self-made), other reagents were of analytical grade.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com