Oil desulphurization method utilizing microwave driving

A petroleum and microwave technology, applied in the field of petroleum desulfurization, can solve the problems of being in the laboratory research stage, low desulfurization efficiency, difficult separation of organic polymers, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

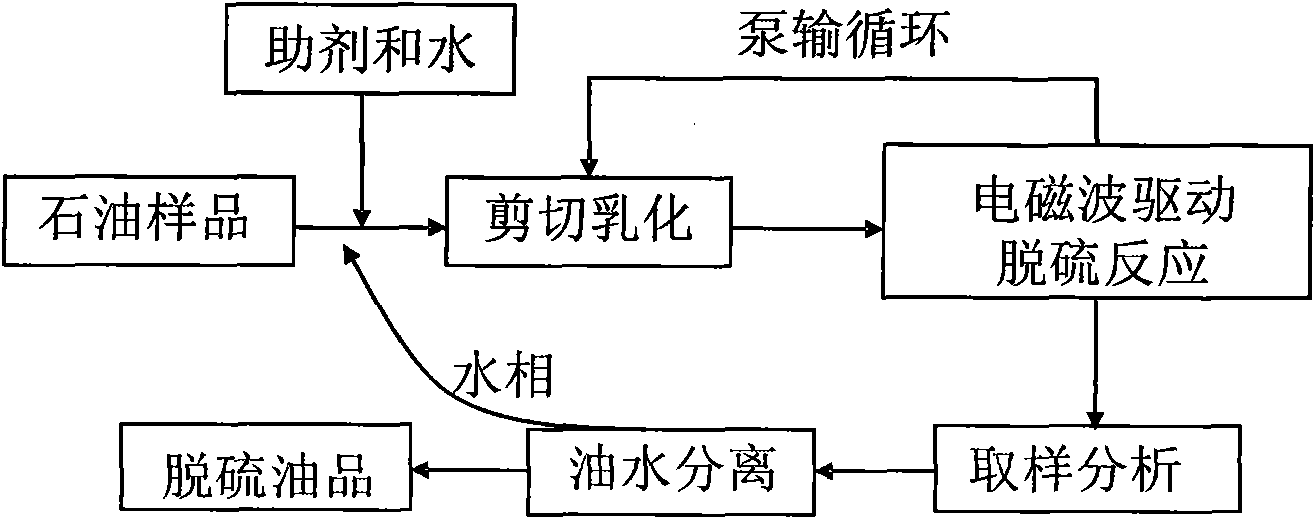

Method used

Image

Examples

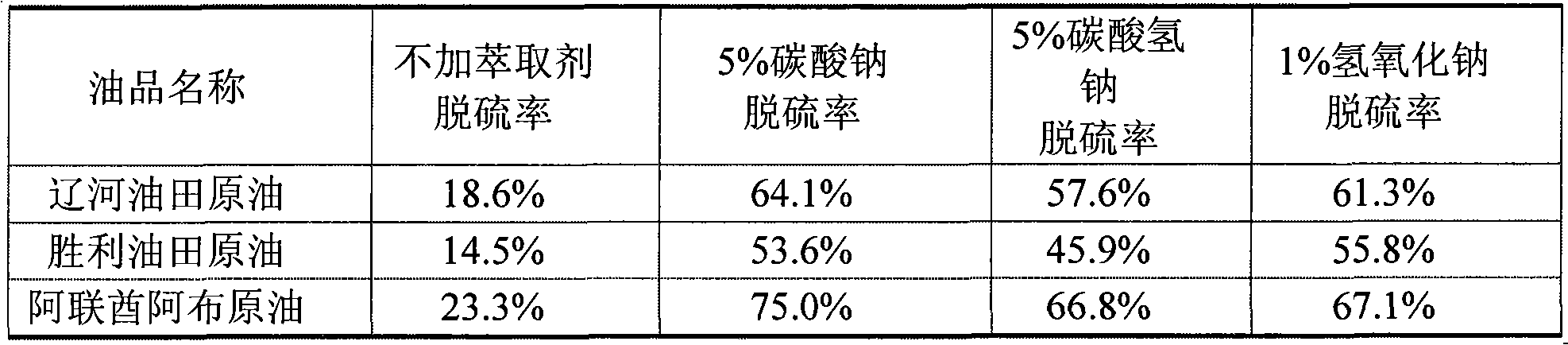

Embodiment 1

[0022] Add 3mL acid (can be formic acid, acetic acid, dichloroacetic acid, trifluoroacetic acid, benzoic acid, citric acid, tartaric acid, ascorbic acid, apple acid, etc.), 8mLH 2 o 2 , an appropriate amount of water (50-200mL), a small amount of emulsifier (mass fraction <0.1%); the mixed solution is placed under a high-shear emulsifier for emulsification for 3-5 minutes, and the rotating speed is 3000-23000 rpm; then the emulsion Transfer to a special reaction flask, react under microwave irradiation conditions for 10 minutes, then add 100mL 5% soda ash aqueous solution (also can be 5% sodium bicarbonate aqueous solution or 1% sodium hydroxide solution) to the desulfurized petroleum sample , standing or centrifuging to separate the desulfurized oil. In this example, microwaves are used to drive petroleum desulfurization. The frequency of the microwaves is 2480 MHz, which belongs to the decimeter wave, and the input power of the microwaves is 450 W. In this example, unless...

Embodiment 2

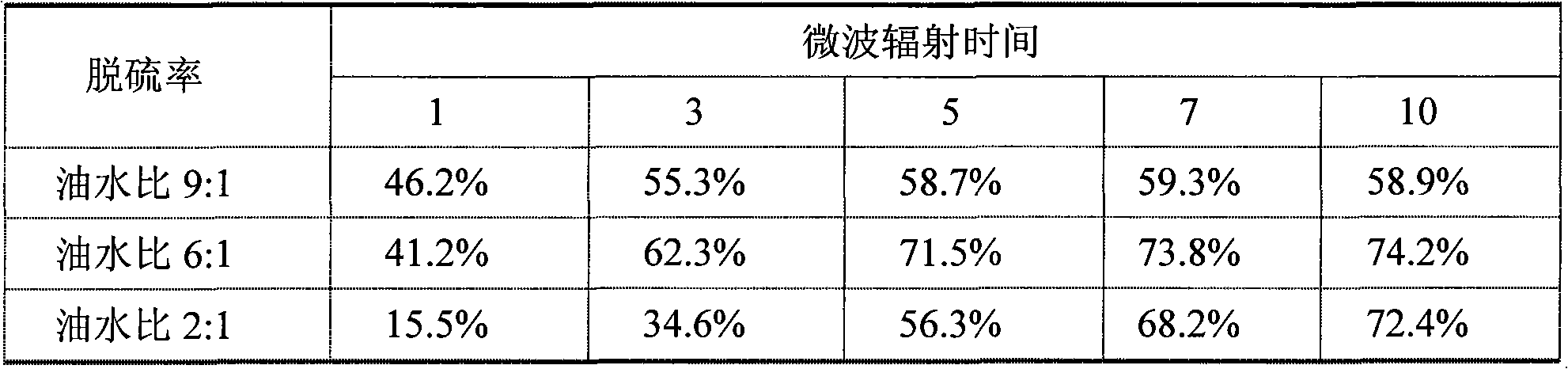

[0026] Example 2: Experiment of microwave radiation time on desulfurization effect

[0027] The treatment was carried out according to the method described in Example 1, except that the microwave irradiation time was 1, 3, 5, 7, and 10 minutes for sampling treatment, and then measured. Other processing methods and reaction conditions are the same.

[0028] Desulfurization results at different microwave irradiation times: (Oil product: UAE Abu crude oil sample)

[0029] time / min

Embodiment 3

[0030] Example 3: Microwave radiation frequency experiment on desulfurization effect

[0031] The treatment was carried out according to the method described in Example 1, except that the microwave radiation frequencies were 850MHz, 1500MHz, and 2480MHz, and the reaction was carried out for 10 minutes, and then measured. Other processing methods and reaction conditions are the same.

[0032] Desulfurization results under different microwave radiation frequencies: (Oil product: UAE Abu crude oil sample)

[0033] frequency

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com