Application of immobilized quinone compound in accelerating denitrification process of microorganism

A compound and microorganism technology, applied in the fields of chemical engineering, biological engineering and environmental engineering, can solve the problems of staying in the laboratory and pilot test stage, complicated process condition control, high equipment investment and operating cost, and reduce secondary pollution. , the effect of low production cost, acceleration speed and capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] One, an immobilized quinone compound, it is prepared by following steps:

[0015] a Weigh sodium alginate and add it to deionized water or normal saline, dissolve it completely in a constant temperature water bath at 90°C, then cool to 35-45°C to make a sodium alginate aqueous solution with a concentration of 6% by mass;

[0016] b Add 1,8-dichloroanthraquinone to the above solution and mix evenly, the weight of the 1,8-dichloroanthraquinone is 5% of the weight of the sodium alginate aqueous solution;

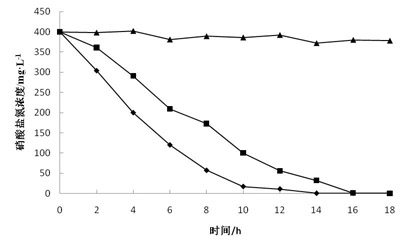

[0017] c Squeeze the mixed solution prepared in the above steps into the calcium chloride solution with a mass percentage concentration of 5% with a medical syringe, and the volume percentage of the mixed solution and the calcium chloride solution is 30%, forming a fixed diameter of 3 to 4mm. The pellets were thawed, cross-linked at room temperature for 5 h, and placed in a refrigerator at 4 °C. figure 1 It is the scanning electron micrograph of the immobilized pellet o...

Embodiment 2

[0028] One, an immobilized quinone compound, it is prepared by following steps:

[0029] a Weigh sodium alginate and add it to deionized water or normal saline, dissolve it completely in a constant temperature water bath at 90°C, then cool to 35~45°C to make a sodium alginate aqueous solution with a concentration of 3% by mass;

[0030] b Add an appropriate amount of 1,5-dichloroanthraquinone to the above solution and mix evenly, the weight of the 1,5-dichloroanthraquinone is 3% of the weight of the sodium alginate aqueous solution;

[0031]c Squeeze the mixed solution prepared in the above steps into the calcium chloride solution with a concentration of 3% by mass percentage with a syringe, and the volume percentage of the mixed solution and the calcium chloride solution is 50%, forming a fixed diameter of 3 to 4 mm. The pellets were thawed, cross-linked at room temperature for 5 h, and placed in a refrigerator at 4 °C for later use.

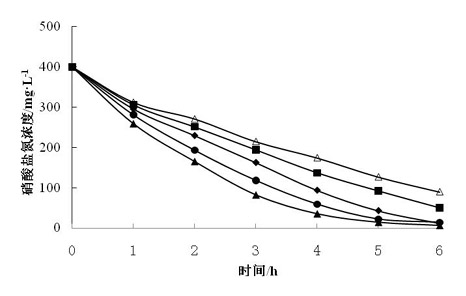

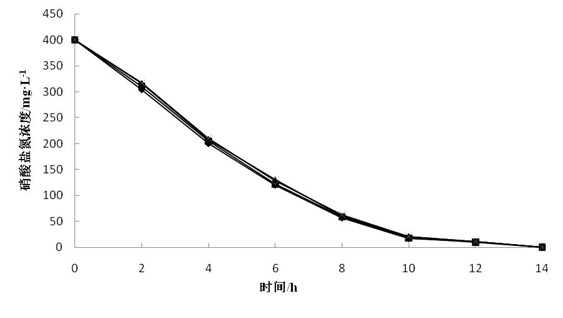

[0032] 2. The application of the immobi...

Embodiment 3

[0037] One, an immobilized quinone compound, it is prepared by following steps:

[0038] a Weigh sodium alginate and add it to deionized water or normal saline, dissolve it completely in a constant temperature water bath at 90°C, then cool to 35-45°C to make a sodium alginate aqueous solution with a concentration of 5% by mass;

[0039] b Add an appropriate amount of 1,4,5,8-tetrachloroanthraquinone to the above solution and mix evenly, the weight of the 1,4,5,8-tetrachloroanthraquinone is 4% of the weight of the sodium alginate aqueous solution;

[0040] c Squeeze the mixed solution prepared by the above steps into a calcium chloride solution with a mass percentage concentration of 2% with a medical syringe, and the volume percentage of the mixed solution and the calcium chloride solution is 40%, forming a 3-4mm diameter The beads were immobilized, cross-linked for 5 h at room temperature, and placed in a refrigerator at 4 °C for later use.

[0041] 2. Application of the imm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com