Nickel-cobalt composite oxide, nickel-cobalt doped oxide and preparation method thereof

A composite oxide and oxide technology, used in electrical components, battery electrodes, circuits, etc., can solve the problems of reducing material capacity activity, difficult internal oxidation, and low degree of oxidation, and achieve complete crystallization, good sphericity, and good activity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

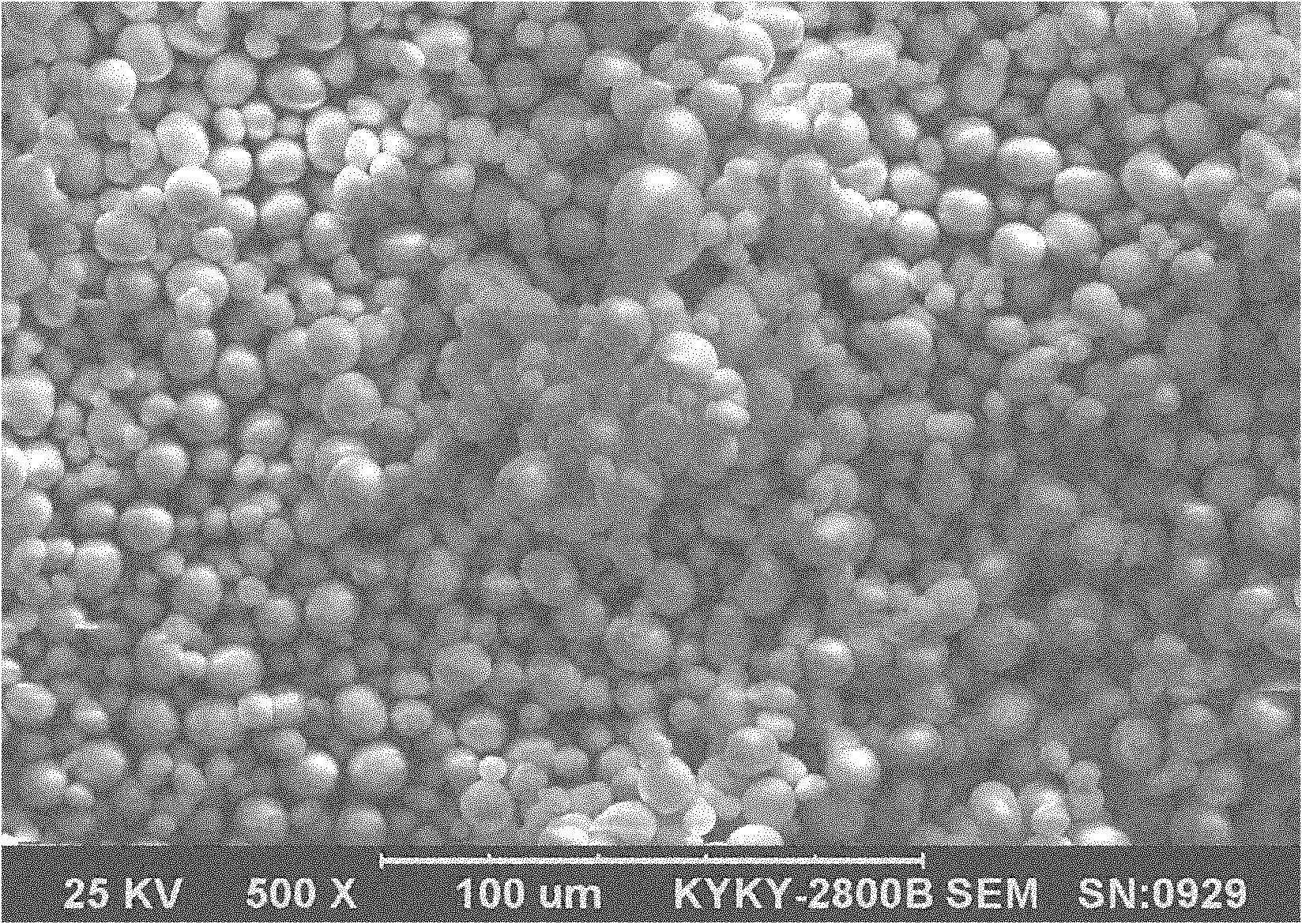

Embodiment 1

[0033] A mixed solution of cobalt sulfate and nickel sulfate is used, wherein the total concentration of nickel and cobalt is 2.0mol / L, the molar ratio of nickel to cobalt is 2.55:0.45, the concentration of sodium hydroxide solution is 5mol / L, and the concentration of ammonia water is 1mol / L. It is a saturated sodium chlorate solution; nickel-cobalt metal solution, lye, and additives are added to the reaction device in parallel, and by adjusting the flow of lye and additives, the control potential reaction potential is 1200mV and the pH value is 11.5, and the nickel-cobalt precipitates simultaneously by Bivalent oxidation to trivalent; keep the potential and pH value after the reaction overflows, and age for 3 hours; after filtering, wash with hot water at 60-70 degrees until the pH of the effluent is 6-8, and the impurities in the washed precipitate The content meets the requirement that the mass content of manganese, calcium, magnesium, manganese, and sodium is less than 150p...

Embodiment 2

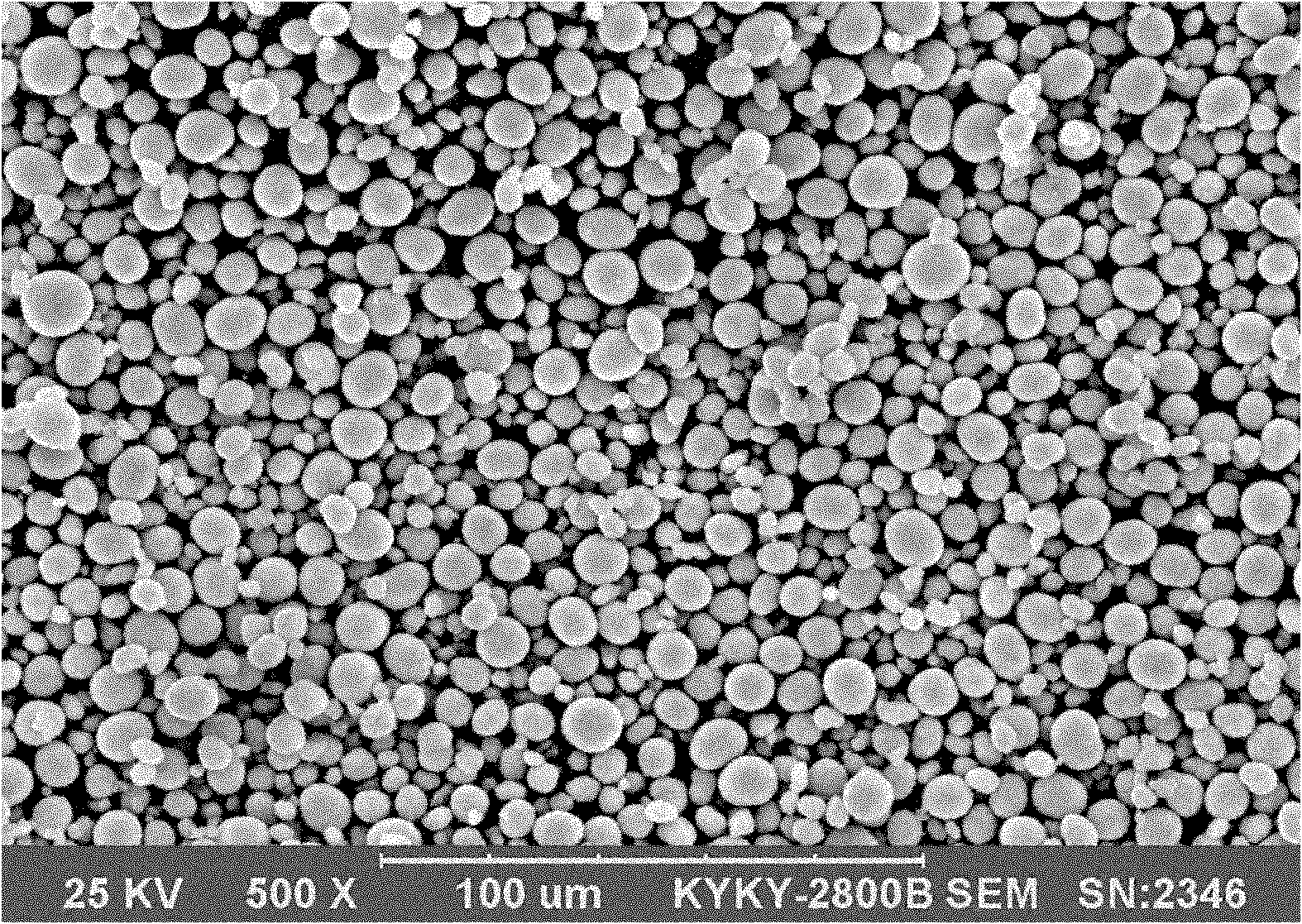

[0036]Use a mixed solution of cobalt chloride and nickel chloride, wherein the total concentration of nickel and cobalt is 1.5mol / L, the molar ratio of nickel to cobalt is 2.12:0.88, the concentration of sodium hydroxide solution is 8mol / L, and the additive is perchloric acid solution Add nickel-cobalt metal solution, lye, and additives into the reaction device in parallel, by adjusting the flow of lye and additives, the potential reaction potential is controlled to be 1500mV and the pH value is 10.8, and the nickel-cobalt is oxidized from divalent to trivalent while precipitation ; Keep the potential and pH value after the reaction overflows, and age for 3.5 hours; after filtering, wash with hot water at 60-70 degrees until the pH value of the effluent is 6-8, and the impurity content in the washed precipitate meets the requirements of manganese and calcium , magnesium, manganese, sodium mass content is less than 150ppm, zinc, copper, iron, lead, mercury, hexavalent chromium m...

Embodiment 3

[0039] Use cobalt chloride, nickel sulfate, aluminum sulfate to prepare mixed solution, wherein the total concentration of nickel, cobalt and aluminum is 1.5mol / L, the molar ratio of nickel, cobalt and aluminum is 2.40: 0.45: 0.15, and the concentration of sodium hydroxide solution is 6mol / L, the concentration of ammonia water is 1.5mol / L, and the additive is a mixed solution of potassium chlorate and hydrogen peroxide; the mixed solution of nickel-cobalt-aluminum metal, lye, and additives are added to the reaction device in parallel, and the potential is controlled by adjusting the flow of lye and additives. The reaction potential is 900mV and the pH value is 11.2; keep the potential and pH value after the reaction overflows, and age for 2 hours; after filtering, wash with hot water at 60-70 degrees until the pH value of the effluent is 6-8, and the impurity content in the precipitate Meet the requirements that the mass content of manganese, calcium, magnesium, manganese, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com