Vinyl polyether and preparation method and application thereof

A technology of vinyl polyether and vinyl ether, applied in the field of polyether, can solve the problems of poor quality stability of water reducer products, few types of polyether monomers, cumbersome process steps, etc., and achieve superior quality, narrow molecular weight distribution, Good effect of process controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

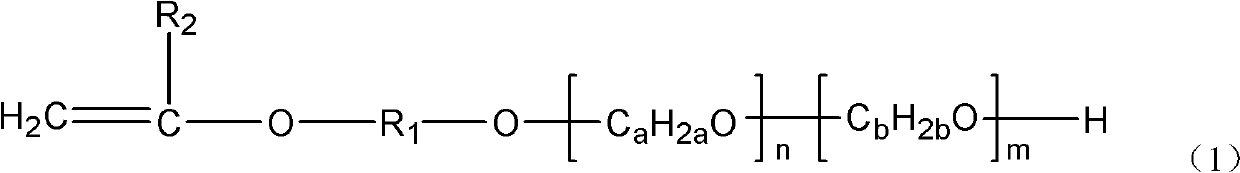

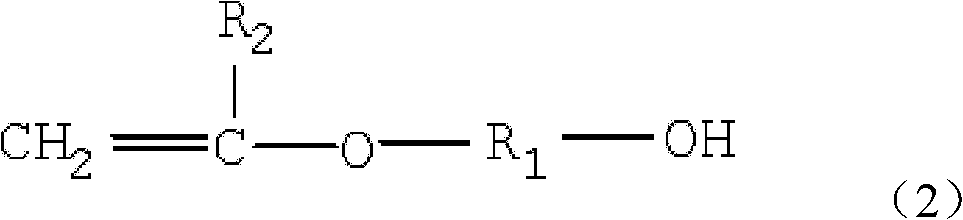

Embodiment 1

[0045] The sodium methylate of 40g ethylene glycol monovinyl ether and 4.9g is joined in the autoclave, with N 2 After the replacement is qualified, start to heat up the reactor and start the mixer at the same time. When the temperature of the kettle rose to 92°C, start to add 2g of ethylene oxide to the reactor. After the temperature rose and the pressure dropped, 49g of oxirane was continuously and stably added to the reactor. During the feeding, the reaction temperature was controlled to be 120-130°C. After the feeding is completed, under constant temperature conditions, carry out the aging reaction for 20 minutes. When the pressure of the kettle no longer drops, start to cool down the materials in the reactor. After the temperature of the reactor is lowered to 70-90°C, phosphoric acid is added to carry out neutralization reaction until the pH of the polyether product is 6.4 to obtain a vinyl polyether product of the present invention, whose structure is shown in the follow...

Embodiment 2

[0048] The potassium hydroxide of 3g diethylene glycol monovinyl ether and 0.25g is joined in the autoclave, with N2 After the replacement is qualified, start to heat up the reactor and start the mixer at the same time. When the temperature of the kettle rises to 110°C, start to add 2g of ethylene oxide and 2g of propylene oxide to the reactor. After the temperature rises and the pressure drops, add 66g of ethylene oxide and 40g of oxyethane continuously and stably. Add propane to the reaction kettle, among them, propylene oxide needs to be added after the ethylene oxide polymerization reaction is completed. During each feeding period, the reaction temperature is controlled at 150-160 ° C. After each feeding is completed, the aging reaction is carried out under constant temperature conditions. After 30 minutes, when the pressure of the kettle no longer drops, start to cool down the materials in the reactor. The temperature of the reactor is lowered to 90°C and acetic acid is ad...

Embodiment 3

[0051] Add 5g of 4-hydroxybutyl vinyl ether and 0.41g of sodium hydroxide and potassium hydroxide into the autoclave, and use N 2 After the replacement is qualified, start to heat up the reactor and start the mixer at the same time. When the temperature of the kettle rises to 110°C, start to add 2g of a mixture of ethylene oxide and butylene oxide to the reaction kettle. After the temperature rises and the pressure drops, add 98g of ethylene oxide and butylene oxide continuously and stably. Add the mixture of alkanes to the reaction kettle, and control the reaction temperature at 130-140°C during the feeding period. After the feeding is completed, under constant temperature conditions, carry out the aging reaction for 40 minutes. When the pressure of the kettle no longer drops, start to cool down the reactor materials. After the temperature of the reactor is lowered to 85°C, dilute sulfuric acid is added to carry out neutralization reaction until the pH of the polyether produc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com