Silica nitride fluorescent powder and preparation method thereof

A silicon oxynitride and phosphor technology, which is used in chemical instruments and methods, luminescent materials, sustainable buildings, etc., can solve the problems of brightness reduction and application limitations, and achieve small brightness reduction, high characteristics, and grain size. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The present invention also provides a preparation method of fluorescent powder, comprising the following steps:

[0059] 1) According to the chemical expression Ba e C f D. g E. 3+a (Al, Ga, In) 3+b o 4+c N 5+d , calculate the amount of each raw material according to the ratio of each element, where -2C +gv D =2, e>0, v C , v D Represents the valence state of C and D; C is one or The luminescent center of several elements, D is an alkaline earth metal other than Ba and a mixture of one or several elements in Zn.

[0060] Each raw material is: one or several barium-containing compounds in barium oxide or barium carbonate or barium oxalate that can be converted into barium oxide, including Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, One or several elements of Tm, Yb, Mn, Cr, Bi, Pb, Fe, oxides, nitrides or compounds that can be converted into oxides or nitrides, containing alkaline earth metals other than Ba and one of Zn Or several simple substances, oxides, n...

Embodiment 1

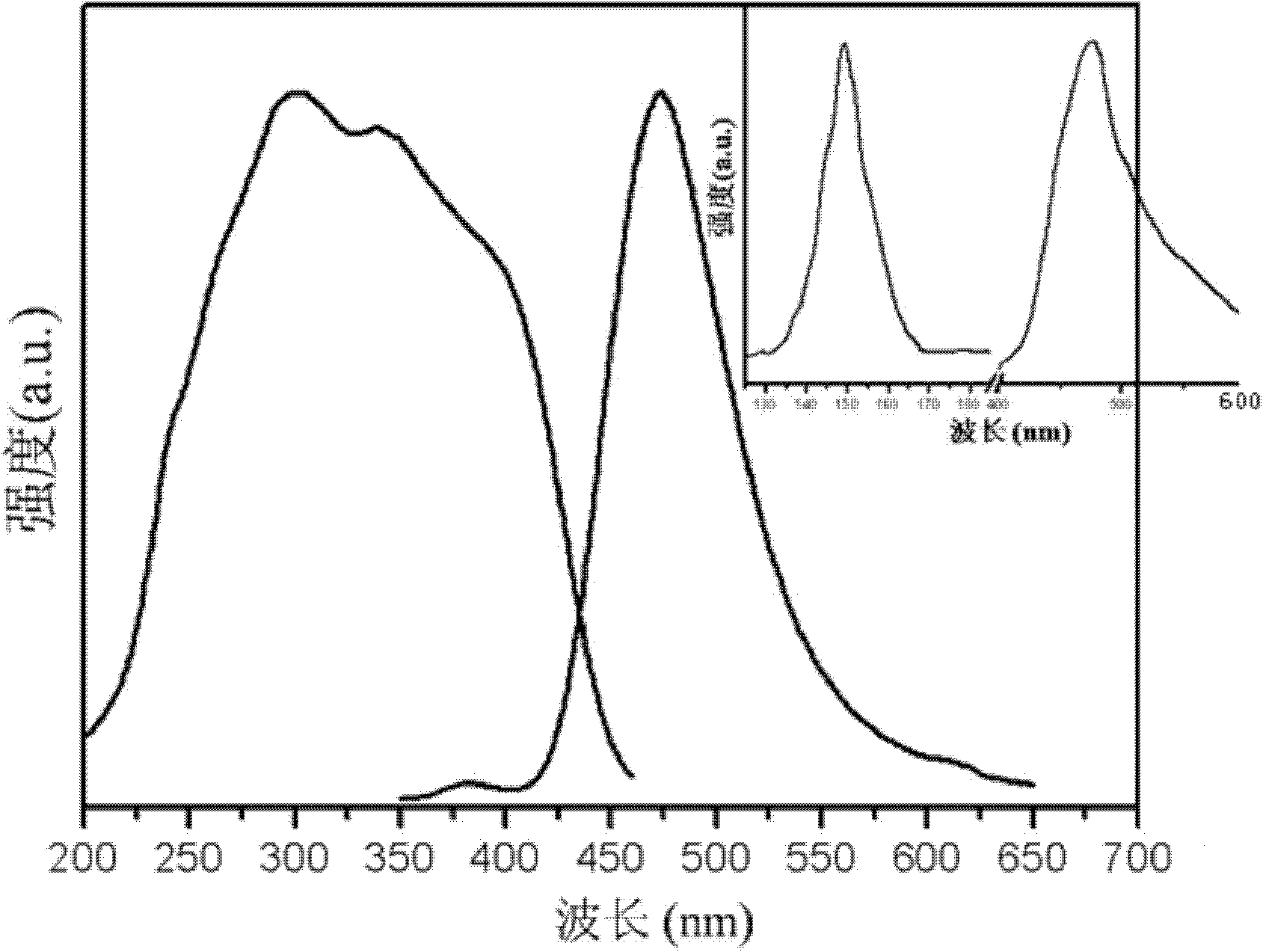

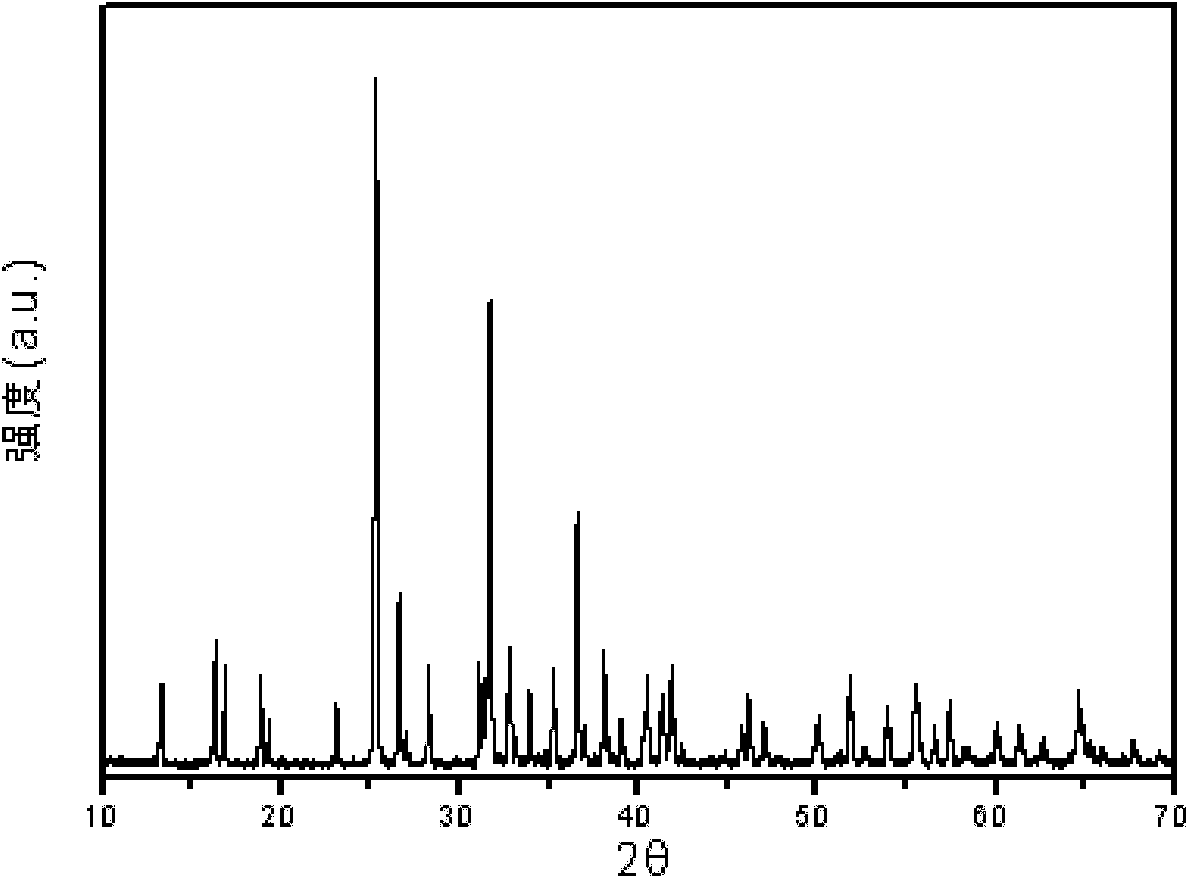

[0074] According to the chemical formula Ba 0.85 Eu 0.15 Si 3 Al 3 o 4 N 5 , Weigh 2.6560gBaCO 3 , 1.7536gSi 3 N 4 , 0.3168gEu 2 o 3 , 0.4968gAlN, 1.2186gAl 2 o 3 starting powder, and added 0.1288gH 3 BO 3 As a flux, put them together into a silica mortar and grind thoroughly for 20 minutes to fully mix various raw materials. Put the mixed powder into a BN crucible with a bulk relative density of about 30%, then cover it with a non-sealed top cover, put it into a corundum tube furnace, and vacuumize the high-temperature furnace to reduce the oxygen content , and then pass into the mixed reducing gas, that is, the flowing N with a purity of 99.999% 2 / NH 3 (Its volume ratio is 10:1) in the ambient atmosphere, the temperature was raised to 800°C at a heating rate of 10°C / min, and then to 1550°C at a heating rate of 5°C / min, kept for 4 hours, and then heated at a temperature of 10°C / min Cool down to 800°C at a cooling rate of min, then cool naturally to room tempe...

Embodiment 2

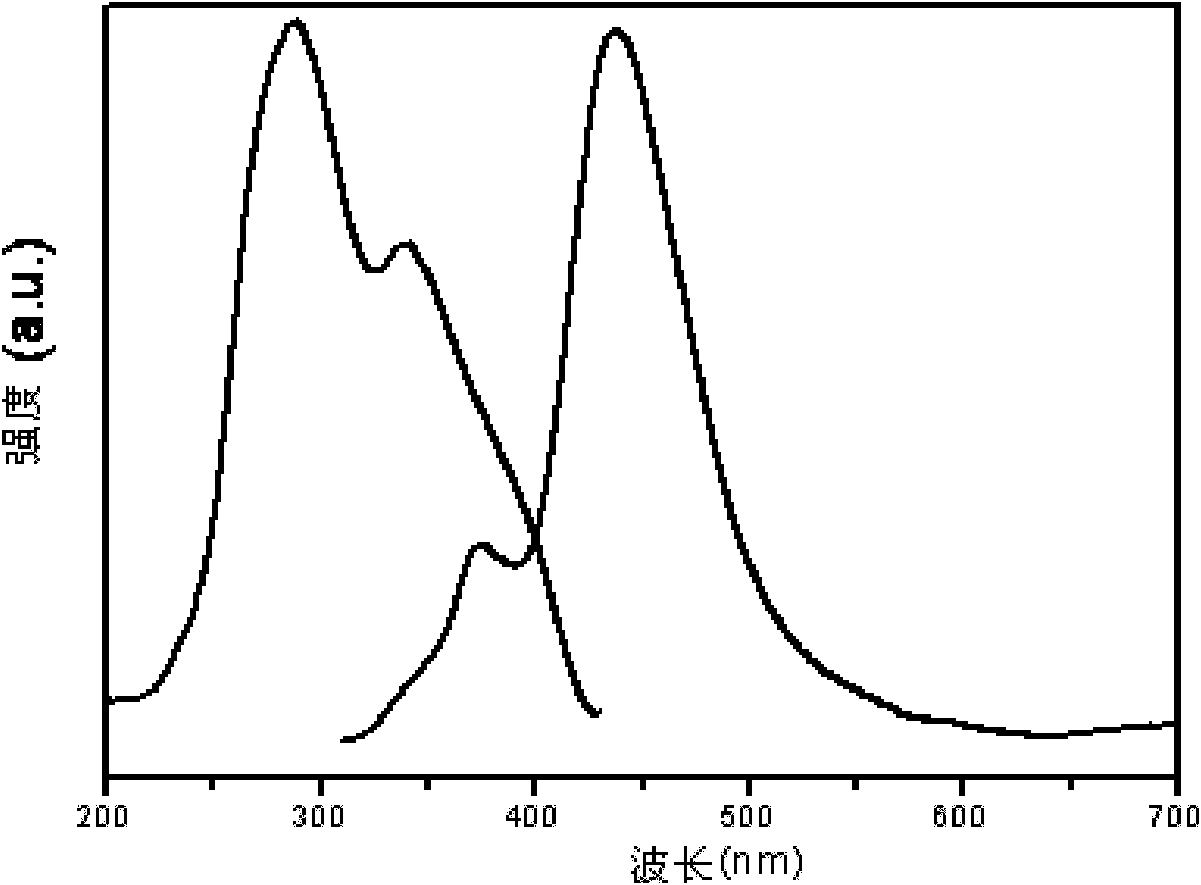

[0076] According to the chemical formula Ba 0.95 Ce 0.05 Si 3 Al 3 o 4 N 5 , weighed 2.2345gBa(NO 3 ) 2 , 0.9139gAl 2 o 3 , 0.3726gAlN, 1.3151gSi 3 N 4 , 0.0775g CeO 2 The starting powder is put into a silicon nitride mortar and ground for 20 minutes to fully mix various raw materials. Put the mixed powder into the BN crucible, the bulk relative density is about 30%, then cover the non-sealed top cover, put the BN crucible into the graphite crucible, and finally put the graphite crucible into the vacuum carbon tube furnace, first Carry out a vacuum operation, and then pass in flowing N with a purity of 99.999% 2 The temperature was raised to 800°C at a heating rate of 4°C / min, then to 1200°C at a heating rate of 6°C / min, and finally to 1600°C at a heating rate of 5°C / min for 8 hours, and then to 5°C / min cooling rate to 1200°C, then naturally cool to room temperature, take out the obtained powder, put it in a mortar and grind it into powder to obtain the required ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Luminous wavelength | aaaaa | aaaaa |

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com