A method and device for rapid and automatic determination of melamine content in dairy products

A technology of melamine and a determination method, applied in the field of food analysis, can solve the problems such as the popularization and application of unfavorable methods, the difficult combination of measurement systems, and the large human error.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

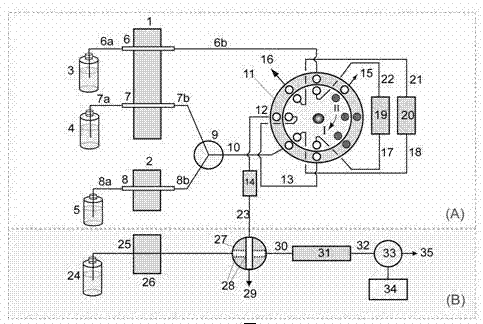

Method used

Image

Examples

Embodiment 1

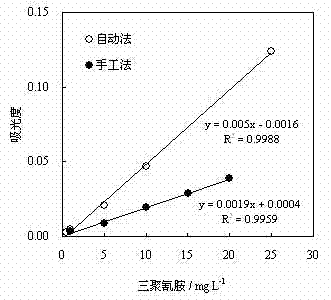

[0050] In this embodiment, melamine standard solutions with different concentrations are used to investigate the concentration effect of the present invention. Experimental conditions of the automatic pretreatment system: the column cleaning solution (5) is a mixture of ultrapure water and methanol (1+1), and its flow rate is 1.05mL min -1 , the dosage is 2.5mL; the volume of the emulsion sample (4) is 6 mL, and its flow rate is 1.2mL min -1 ; The eluent (3) is 7.0% (v / v) ammoniated methanol solution, and its flow rate is 1.48mL min -1 , the elution time is 30s; the extraction column 2 (20) has a length of 40 mm, an inner diameter of 3 mm, a filler particle size of 45 μm, and a mass of 60 mg; the first connecting tube (12) uses a polyamide with a length of 25 cm and an inner diameter of 0.8 mm Tetrafluoroethylene pipe; the lengths of the three-way outlet pipe (10), the first connecting pipe (12), the fourth connecting pipe (18), the fifth connecting pipe (21) and the seventh ...

Embodiment 2

[0052] In this embodiment, the reproducibility of the present invention, four kinds of dairy products containing melamine and the recovery rate of standard addition were measured. The measurement results of the reproducibility (n=11) are shown in Table 1, and the results of the standard recovery are shown in Table 2. According to the data in Table 1, it can be seen that the RSD<3.88% of the measurement results of the present invention means that the precision is much higher than the given value of the national standard (RSD<10.0%). According to the data in Table 2, it can be seen that the standard recovery of the present invention is between 95.4-108.1%, and the result is satisfactory. It can be seen that the present invention can fully meet the requirements of pretreatment and rapid determination of melamine content determination in dairy products.

[0053]

[0054]

[0055]

Embodiment 3

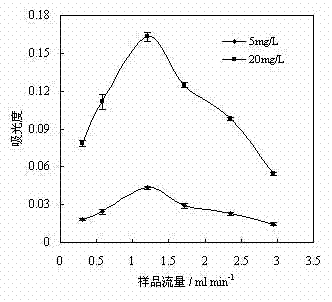

[0057] In this embodiment, the present invention uses 5 mg / L and 20 mg / L melamine standard solutions as test samples (4) to investigate the effect of enriching melamine in the extraction column under different sample flow rates. Experimental conditions: the fixed sample volume is 8.0mL, the column cleaning solution (5) is a mixture of water and methanol (50 / 50, v / v), the cleaning time is 200s; the cleaning flow rate is 0.9mL min -1 , the eluent (3) is 5.0% (v / v) ammoniated methanol, and its flow rate is 1.17mL min -1 , the elution time is 45s. See the experimental results image 3 . It can be seen that, in the present invention, as the sample flow increases, the absorbance gradually increases first and then gradually decreases; when the sample flow is 1.2mL min -1 , the absorbance value is maximum. That is, the melamine enrichment effect of the extraction column is the best at this time.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com