A kind of solid chlorine dioxide effervescent tablet and preparation method thereof

A chlorine dioxide effervescent tablet, chlorine dioxide parent technology, applied in the directions of botanical equipment and methods, biocides, disinfectants, etc., can solve the problems of reducing chlorine dioxide yield, equipment corrosion, complex equipment and the like, To achieve the effect of speeding up the dissolution rate, improving the reaction kinetics, improving the conversion rate and chemical yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

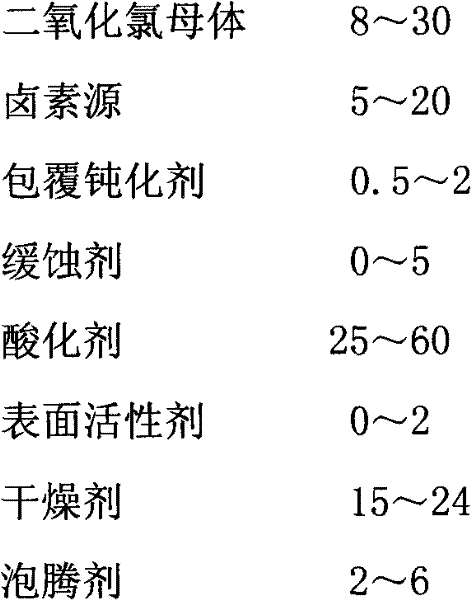

Method used

Image

Examples

Embodiment 1

[0088] Tablets weighing 1.0 g were prepared using the following formulation.

[0089] Sodium chlorite 20kg

[0090] Bleach 10kg

[0091] Nano Zinc Oxide 0.5kg

[0092] Nano Magnesium Oxide 0.5kg

[0093] Sodium citrate 3kg

[0094] D-malic acid 42kg

[0095] Sucrose fatty acid ester 1kg

[0096] Anhydrous magnesium sulfate 18kg

[0097] Sodium bicarbonate 5kg

[0098] The tablet preparation process is carried out according to the following steps:

[0099] a. Add 0.25kg nanometer zinc oxide, 0.25kg nanometer magnesium oxide, 20kg sodium chlorite and 5kg sodium bicarbonate into the first mixing container, mix for 15-20 minutes, and use a coating passivator to treat the carbon dioxide The chlorine matrix is coated and passivated for use.

[0100] b. Add 0.25kg of nano-zinc oxide, 0.25kg of nano-magnesium oxide and 10kg of bleaching essence to the second mixing container, mix for 15-20 minutes, and use a coating passivator to coat and passivate the bleaching essence ,s...

Embodiment 2

[0108] Tablets weighing 4.0 g were prepared using the following formulation.

[0109] Sodium chlorite 24kg

[0110] Bleach 12kg

[0111] Nano Zinc Oxide 1.0kg

[0112] Nano Magnesium Oxide 0.5kg

[0113] Nano magnesium carbonate 0.5kg

[0114] Sodium acetate 3kg

[0115] L-malic acid 41kg

[0116] Saponin 1kg

[0117] Anhydrous calcium chloride 15kg

[0118] Sodium bicarbonate 2.0kg

[0119] The tablet preparation process is carried out according to the following steps:

[0120] a. Add 0.5kg nano-zinc oxide, 0.25kg nano-magnesium oxide, 0.25kg nano-magnesium carbonate, 24kg sodium chlorite and 2kg sodium bicarbonate into the first mixing container, mix for 15-20 minutes, and use a coating blunt The oxidizing agent is used to coat and passivate the chlorine dioxide precursor for use.

[0121] b. Add 0.5kg nano-zinc oxide, 0.25kg nano-magnesium oxide, 0.25kg nano-magnesium carbonate and 12kg bleaching essence to the second mixing container, mix for 15-20 minutes, and u...

Embodiment 3

[0129] Tablets weighing 5.0 g were prepared using the following formulation.

[0130] Sodium chlorite 8kg

[0131] Bleach 5kg

[0132] Nano Magnesium Oxide 1.0kg

[0133] L-malic acid 25kg

[0134] Anhydrous sodium sulfate 15kg

[0135] Sodium carbonate 2.0kg

[0136] The tablet preparation process is carried out according to the following steps:

[0137] a. Add 0.5kg of nano-magnesium oxide, 8kg of sodium chlorite and 2kg of sodium carbonate into the first mixing container, mix for 15-20 minutes, and use a coating passivator to coat and passivate the chlorine dioxide precursor ,stand-by.

[0138] b. Add 0.5 kg of nano-magnesium oxide and 8 kg of bleaching essence into the second mixing container, mix for 15-20 minutes, and coat and passivate the bleaching essence with a coating passivation agent for use.

[0139] c. Add the mixture in the first mixing vessel in step a to the mixture in the second mixing vessel in step b, then add 15 kg of anhydrous sodium sulfate, mix ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com