Polymer gel electrolyte and preparation method thereof

A technology of gel electrolyte and polymer, which is applied in the direction of capacitor electrolyte/absorbent, circuit, photosensitive equipment, etc. It can solve the problems of battery packaging difficulties, dye desorption, solvent volatilization, etc., and achieve fast interface charge transmission speed and interface resistance. Effects of small, mild operating conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

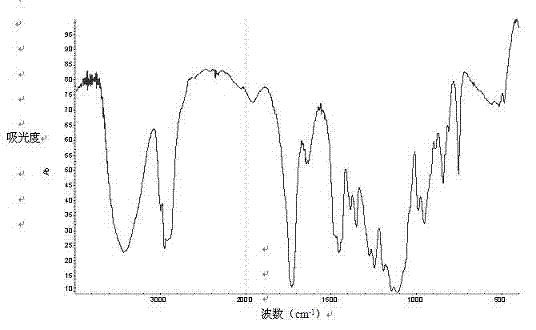

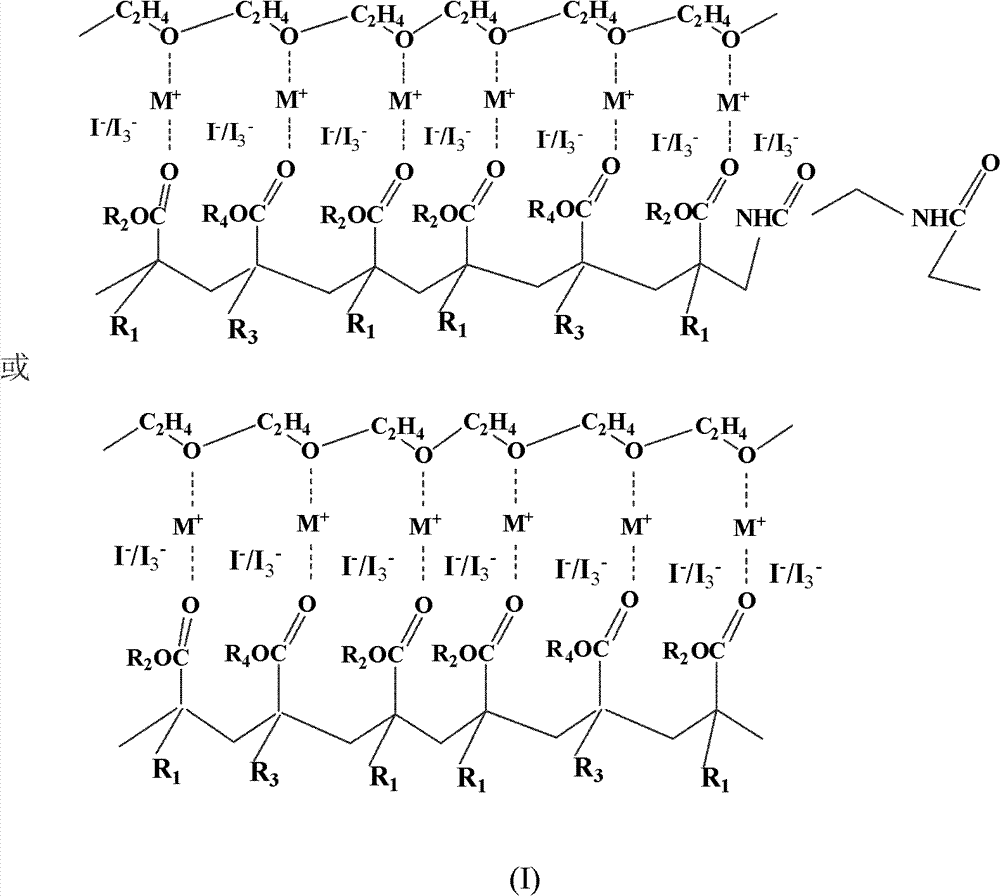

[0034] The preparation method of polymer gel electrolyte is through PA / PEG polymer and redox pair iodide / I 2 The mixed reaction forms the polymer gel electrolyte of the present invention. Specifically, the preparation method of the present invention comprises the following steps:

[0035] Step 1: Preparation of PA / PEG polymer

[0036] The reaction flask is respectively connected with condensed water, mechanical stirring and flowing nitrogen. First, polyethylene glycol, cross-linking agent N, N-methylenebisacrylamide BIS (also optional) and solvent are added to the reaction flask. Monomers such as methyl methacrylate MMA, methyl acrylate, butyl acrylate BA, butyl methacrylate, hydroxyethyl methacrylate, hydroxypropyl acrylate, fluoroheptyl acrylate, fluoroheptyl methacrylate Dissolve in the solvent; dissolve the initiator in the solvent, flow nitrogen gas, raise the temperature at 50-90°C, slowly drop the acrylate monomer solution and the initiator solution into the reaction ...

Embodiment 1

[0057] Step 1: Preparation of PA / PEG polymer

[0058] The reaction flask was respectively connected with condensed water, mechanical stirring and flowing nitrogen. First, 4.29 g of polyethylene glycol and 5 g of tetrahydrofuran were added to the reaction flask, and 8.5 g of acrylate monomer MMA and 0.5 g of BA were dissolved in 10 g of solvent; Dissolve 0.1 g of azobisisobutyronitrile in a solvent of 5 g of tetrahydrofuran, flow nitrogen gas, raise the temperature to 70° C., slowly drop the acrylate monomer solution and initiator solvent into the reaction flask simultaneously, and react for 24 hours.

[0059] In this embodiment, the mass ratio of monomer MMA:BA:initiator AIBN:PEG:solvent is 1:0.0588:0.01176:0.50:2.35. The molecular formula of polyethylene glycol PEG is HO-(CH 2 CH 2 O) n H, n stands for CH 2 CH 2 The average value of the number of repeating units of O is an integer of 9, and it is a commercially available reagent grade product.

[0060] Obtaining the mol...

Embodiment 2

[0080] Step 1: Preparation of PA / PEG polymer

[0081] Same as the first step in Example 1.

[0082] Step 2: Preparation of Polymer Gel Electrolyte

[0083] Prepare iodide / I 2 Electrolyte solution: same as the first step of embodiment 1

[0084] Preparation of polymer gel electrolyte: Take 4g of PA / PEG polymer treated in the first step and add it to 4g of the above electrolyte solution, then add 0.20g of electrolyte additive tert-butylpyridine, seal it in a flask, and heat it at 80°C Stir to form a homogeneous viscous solution, and then cool to room temperature to obtain a polymer gel electrolyte.

[0085] Wherein, the weight ratio of PA / PEG polymer:electrolyte solution:electrolyte additive is 1:1:0.05.

[0086] The above-mentioned electrolyte additive tert-butylpyridine can be replaced by pyridine or guanidine isothiocyanate GuSCN.

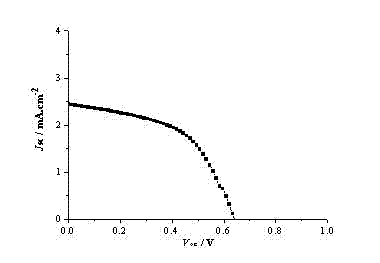

[0087] Dye-sensitized solar cells DSSC were prepared using the obtained polymer gel electrolyte. Its photovoltaic conversion efficiency η w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com