Method for preparing p-aminodiphenylamine

A technology of p-aminodiphenylamine and nitrodiphenylamine, which is applied in the field of preparation of p-aminodiphenylamine, can solve problems such as difficult solvent recovery, long hydrogenation time, and hydrogenation of azobenzene, so as to avoid the control of moisture content, Simple operation and improved reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1. 50g of powdered activated carbon was pretreated, soaked in 200g of 3% nitric acid solution at 30°C for 8 hours, washed with deionized water until neutral, then soaked in 3% hydrogen peroxide solution for 4 hours, washed, and dried at 105°C for 16 hours.

[0030] Get the treated activated carbon 20g for later use. Dissolve a certain amount of palladium chloride and lanthanum nitrate in 100mL of 2% hydrochloric acid solution, pour it into a container filled with carrier activated carbon, stir for 4 hours, take it out, add 10mL of 5% formaldehyde for reduction, and use 5% sodium hydroxide The pH of the solution was adjusted to 6-8, maintained for 4 hours, taken out, washed with deionized water, and vacuum-dried at 80°C for 8 hours to obtain the finished catalyst, which was designated as Cat1.

Embodiment 2

[0031] Example 2. 50g of powdered activated carbon was pretreated, soaked in 200g of 3% hydrochloric acid solution at 60°C for 8 hours, washed with deionized water until neutral, soaked in 5% hydrogen peroxide solution for 4 hours, washed, and dried at 105°C for 16 hours.

[0032] Get the treated activated carbon 20g for later use. Dissolve a certain amount of palladium nitrate and cerium nitrate in 100ml of 2% nitric acid solution, pour it into a container filled with carrier activated carbon, stir for 5 hours, take it out, add 10ml of 5% hydrazine hydrate for reduction, and use 5% sodium hydroxide The pH of the solution was adjusted to 6-8, maintained for 4 hours, taken out, washed with deionized water, and vacuum-dried at 80°C for 8 hours to obtain the finished catalyst, which was designated as Cat2.

Embodiment 3-6

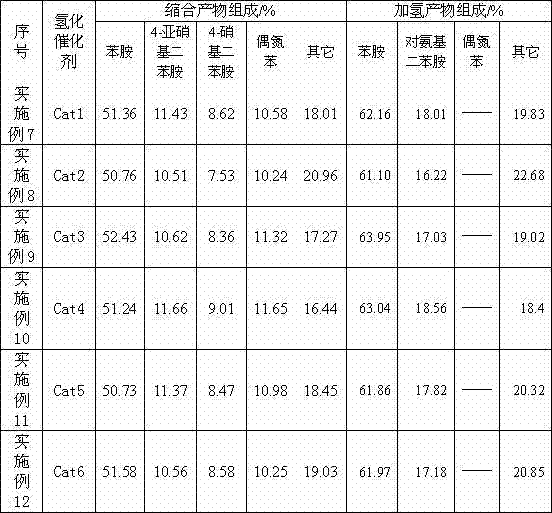

[0033] Example 3-6. The catalyst was prepared by the method of Example 1, and the contents of each component were shown in the table.

[0034] Table 1 The content of each component in the catalyst

[0035] Example catalyst palladium rare earth element 1 Cat1 5% (added in the form of palladium chloride) La (added in the form of lanthanum nitrate) 0.05% 2 Cat2 7% (added in the form of palladium nitrate) La (added in the form of lanthanum chloride) 0.70% 3 Cat3 9% (added in the form of palladium acetate) Ce (added in the form of cerium chloride) 0.18% 4 Cat4 11% (added in the form of palladium chloride) Pr (added in the form of praseodymium chloride) 0.33% 5 Cat5 13% (added in the form of palladium nitrate) Nd (added as neodymium chloride) 0.65% 6 Cat6 15% (added in the form of palladium acetate) Sm (added as samarium chloride) 0.90%

[0036] Above-mentioned embodiment 1-6 is the preparation of h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com