Porous magnesium alloy three-dimensional reinforced absorbable medical compound material and preparation method thereof

A composite material and porous magnesium technology, which is applied in the field of porous magnesium alloy three-dimensional reinforced absorbable medical composite materials, bone internal fixation composite materials, and orthopaedic internal fixation materials, which can solve the problem of reducing the ability of fracture fixation, unable to degrade and absorb, and affecting imaging examinations. Cancer patients with chemotherapy and other problems, to achieve the effect of improving toughness and overcoming too high and too strong acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

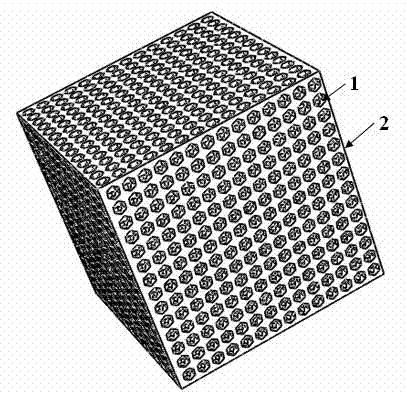

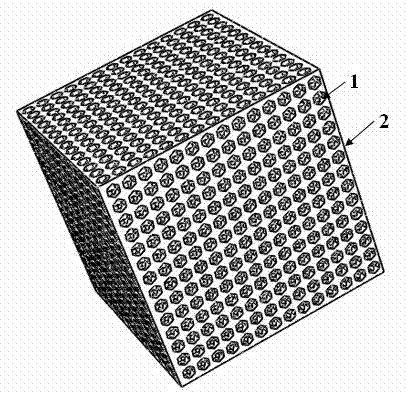

[0039] 5g of AZ31B porous magnesium alloy reinforcement with a porosity of 50% was prepared by powder metallurgy molding method, and 10g / L sodium silicate, 2g / L NaOH and 10g / L hydroxyapatite nanoparticles were used as micro-arc oxidation electrolysis In the liquid system, the magnesium alloy reinforcement is immersed in it and a voltage of 400V is applied for 20 minutes of micro-arc oxidation treatment to form a ceramic protective film rich in magnesium oxide, magnesium silicate and hydroxyapatite on the surface in situ. Take 6g of polylactic acid with a molecular weight of 200,000, heat it to 220°C and melt it, inject it into the cavity of a cube mold with a side length of 20mm, mix and stir the polylactic acid solution with the porous magnesium alloy structure evenly, so that the pores in the porous magnesium alloy will be filled. Filled with polylactic acid solution, vacuum dried at 90°C for later use. Then press at 170° C. and 10 MPa for 20 minutes, and cool to room temper...

Embodiment 2

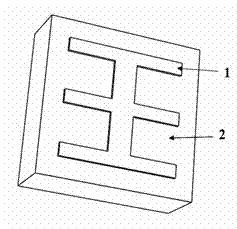

[0041] Using the die-casting molding process, prepare a "king"-shaped three-dimensional magnesium alloy frame reinforcement 2.3g composed of support rods, and pass it through the micro-arc oxidation treatment method as shown in Example 1 to obtain magnesium oxide-rich , magnesium silicate, hydroxyapatite film layer. The three-dimensional porous magnesium alloy frame reinforcement is placed in a 20mmx40mmx5mm die cavity and fixed. Take 4.8g of polylactic acid with a molecular weight of 200,000, and directly mix the polylactic acid powder with the three-dimensional porous magnesium alloy frame reinforcement, so that the three-dimensional porous magnesium alloy frame is evenly filled with polylactic acid powder, and set aside. The mixture was molded at 200° C. under 10 MPa pressure for 10 minutes, and cooled to normal temperature. Finally, it can be machined into the required internal fixation products for orthopedics.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com