Resistive random access memory based on polymer/metal ion composite system, and preparation method for resistive random access memory

A resistive memory, metal ion technology, applied in static memory, digital memory information, semiconductor/solid-state device manufacturing, etc., can solve the problems of performance difference, device failure, low yield, etc., to achieve excellent resistive characteristics, high application The effect of value, low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

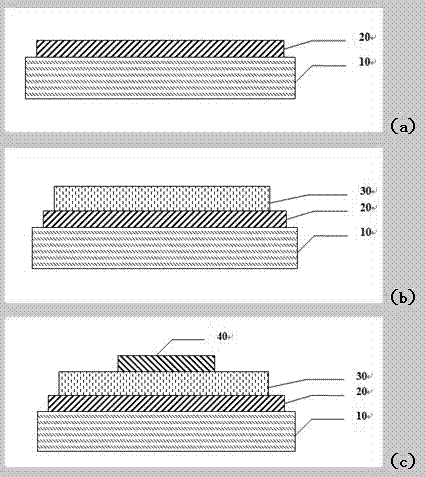

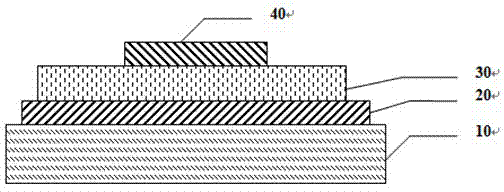

[0028] Step 1, forming the bottom electrode 20 on the insulating substrate 10 .

[0029] In this step, the material used for the bottom electrode 20 can be a metal electrode of Cu, W, Co, Ni, Ta, Ti, Zn, Al, Cr or a composite metal electrode of two or more combinations, and can be indium oxide doped Tin (ITO), zinc oxide doped with aluminum (AZO), can also be P-type silicon, N-type silicon materials. It can be formed by methods such as physical vapor deposition, chemical vapor deposition, or electrochemical deposition. The electrode can be formed on the surface of insulating substrates such as silicon dioxide, glass, quartz, ceramics, or other insulating flexible substrate materials. Parameters such as width and thickness of the electrodes are not limiting, and those skilled in the art can make choices according to specific conditions. The patterning of the bottom electrode can be realized through photolithography process steps. In this embodiment, a thermal evaporation met...

Embodiment 2

[0034] In this embodiment, the storage device is fabricated in the same manner as in the first embodiment, except that the second step is to form a polyimide / sodium ion composite film 30 on the surface of the bottom electrode 20 . Specifically:

[0035] In this embodiment, 2,3,3',4-biphenyltetracarboxylic dianhydride and p-aniline are mixed in a certain proportion and dissolved in nitrogen, a polyamic acid solution formed in nitrogen-dimethylformamide. Mix sodium chloride with the formed polyamic acid solution in proportion (the concentration of sodium ions is 0.01mol / L), and ultrasonically disperse to form a uniform polyamic acid / sodium ion mixed solution. The polyamic acid / sodium ion mixed solution is applied on the top of the bottom electrode 20 by a spin coating method to form a polyamic acid / sodium ion composite film. Under the protection of argon atmosphere, the polyimide / sodium ion composite film 30 is formed by heat treatment at 350 degrees centigrade for 1 hour.

Embodiment 3

[0037] In this embodiment, the storage device is fabricated in the same manner as in the first embodiment, except that the second step is to form a polyimide / potassium ion composite film 30 on the surface of the bottom electrode 20 . Specifically:

[0038] In this embodiment, 2,3,3',4-biphenyltetracarboxylic dianhydride and p-aniline are mixed in a certain proportion and dissolved in nitrogen, a polyamic acid solution formed in nitrogen-dimethylformamide. Potassium chloride was mixed with the formed polyamic acid solution in proportion (the concentration of potassium ions was 0.01 mol / L), and ultrasonically dispersed to form a uniform polyamic acid / potassium ion mixed solution. The polyamic acid / potassium ion mixed solution is applied on the top of the bottom electrode 20 by a spin coating method to form a polyamic acid / potassium ion composite film. Under the protection of argon atmosphere, the polyimide / potassium ion composite film 30 is formed by heat treatment at 350 degre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com